ANSI B16.9 Tantalum Buttweld Fittings Weight, Dimensions Chart in mm, kg, PDF online

Tantalum buttweld fittings are specialized components used in industrial applications that require

resistance to corrosion and high-temperature environments. Tantalum is a rare and highly

corrosion-resistant metal, which makes it ideal for use in aggressive chemical processing and

high-temperature applications. Tantalum buttweld fittings are typically joined to pipes using a buttweld

process, in which the ends of the pipe and fitting are heated to a high temperature and then pressed

together. This process creates a strong, leak-tight joint. Tantalum is known for its exceptional

corrosion resistance, particularly against strong acids, such as hydrochloric acid, sulfuric acid, and

nitric acid. This property makes tantalum buttweld fittings suitable for applications where other

materials would corrode quickly. Tantalum can withstand high temperatures, making it suitable for

applications where elevated temperatures are involved, such as in chemical reactors and heat exchangers.

Tantalum buttweld fittings are typically made from high-purity tantalum to meet the strict requirements

of industries like the semiconductor and pharmaceutical industries, where contamination can be

detrimental to the final product. These buttweld fittings come in various sizes and types, all of which

is shown in tantalum buttweld fittings weight and dimensions chart PDF on this page.Tantalum buttweld

fittings are relatively low-maintenance due to their corrosion resistance.

Features:

- Excellent corrosion resistance

- Good weldability

- Long service life

- High strength

- Temperature resistance

- Low maintenance costs

- Reduced risk of downtime

Applications:

- Oil and gas industry: pipelines, heat exchangers, pressure vessels, offshore structures

- Chemical processing industry: reactors, distillation columns, piping systems

- Marine industry: seawater piping systems, desalination plants, ship hulls

- Power generation industry: boilers, condensers, piping systems

- Other industries: food processing, pharmaceutical, pulp and paper

Specifications of Tantalum Buttweld Fittings

The dimensional standard of the buttweld fittings we supply are in accordance with the American National

Standards Institute (ANSI): ANSI B16.9, MSS SP43 and MSS SP75. All the specifications of tantalum

buttweld

fittings are mentioned in the weight and dimensions chart PDF in mm and kg units below.

Types of Tantalum Buttweld fitting:

The types of tantalum buttweld fitting are:

- Elbows

- Tees

- Reducers

- Caps

- Stub Ends

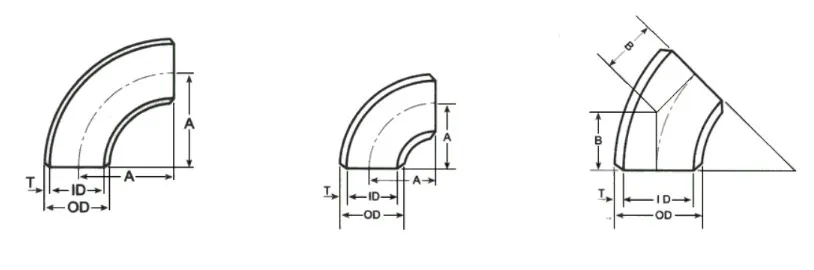

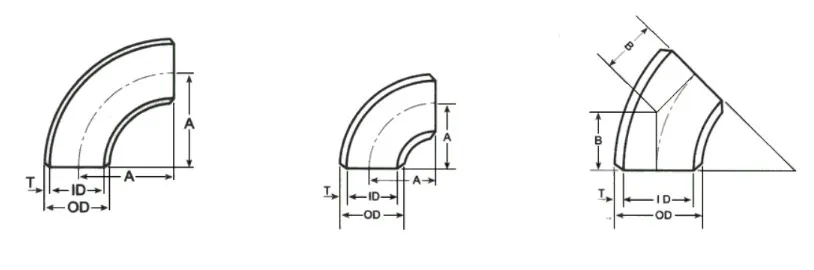

ANSI B16.9/B16.28 90°/45° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel(OD) |

Center to End |

| Long Radius Elbow |

Short Radius Elbow |

| 90 degree. A |

45 degree B |

90 degree A |

| 1/2 |

21.3 |

38.1 |

15.7 |

- |

| 3/4 |

26.7 |

38.1 |

19.1 |

- |

| 1 |

33.4 |

38.1 |

22.4 |

25.4 |

| 1-1/4 |

42.2 |

47.8 |

25.4 |

31.8 |

| 1-1/2 |

48.3 |

57.2 |

28.4 |

38.1 |

| 2 |

60.3 |

76.2 |

35.1 |

50.8 |

| 2-1/2 |

73.0 |

95.2 |

44.4 |

63.5 |

| 3 |

88.9 |

114.3 |

50.8 |

76.2 |

| 3-1/2 |

101.6 |

133.4 |

57.2 |

88.9 |

| 4 |

114.3 |

152.4 |

63.5 |

101.6 |

| 5 |

141.3 |

190.5 |

79.2 |

127.0 |

| 6 |

168.3 |

228.6 |

95.2 |

152.4 |

| 8 |

219.1 |

304.8 |

127.0 |

203.2 |

| 10 |

273.1 |

381.0 |

158.8 |

254.0 |

| 12 |

323.9 |

457.2 |

190.5 |

304.8 |

| 14 |

355.6 |

533.4 |

222.2 |

355.6 |

| 16 |

406.4 |

609.6 |

254.0 |

406.4 |

| 18 |

457.2 |

685.8 |

285.8 |

457.2 |

| 20 |

508.0 |

762.0 |

317.5 |

508.0 |

| 22 |

558.8 |

838.2 |

342.9 |

558.8 |

| 24 |

609.6 |

914.4 |

381.0 |

609.6 |

| 26 |

660.4 |

990.6 |

406.4 |

660.4 |

| 28 |

711.2 |

1066.8 |

438.2 |

711.2 |

| 30 |

762.0 |

1143.0 |

469.9 |

762.0 |

| 32 |

812.8 |

1219.2 |

501.6 |

812.8 |

| 34 |

863.6 |

1295.4 |

533.4 |

863.6 |

| 36 |

914.4 |

1371.6 |

565.2 |

914.4 |

| 38 |

965.2 |

1447.8 |

599.9 |

- |

| 40 |

1016.0 |

1524.0 |

632.0 |

1016.0 |

| 42 |

1066.8 |

1600.2 |

660.4 |

1066.8 |

| 44 |

1117.6 |

1676.4 |

695.5 |

1117.6 |

| 46 |

1168.4 |

1752.6 |

726.9 |

- |

| 48 |

1219.2 |

1828.8 |

759.0 |

1219.2 |

| 52* |

1320.8 |

- |

- |

1320.8 |

| 54* |

1371.6 |

2057.4 |

852.2 |

1371.6 |

| 56* |

1422.4 |

2133.6 |

883.8 |

1422.4 |

| 60* |

1524.0 |

2286.0 |

946.9 |

1524.0 |

| 66* |

1676.4 |

2514.6 |

1041.6 |

- |

| 68* |

1727.0 |

2591 |

1073 |

1727 |

| 72* |

1829.0 |

2743 |

1137 |

1829 |

| 76* |

1930.0 |

2896 |

1199 |

1930 |

| 80* |

2032.0 |

3048 |

1263 |

2032 |

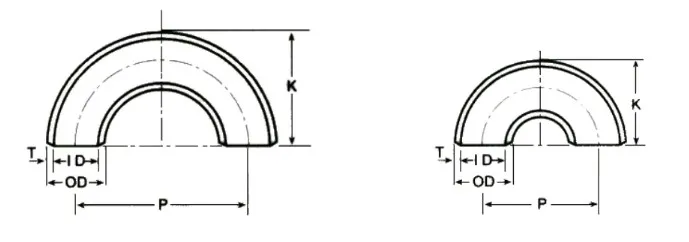

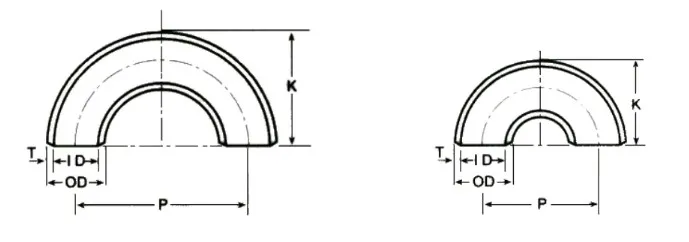

ANSI B16.9/B16.28 180° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel OD |

Long Radius Elbow |

Short Radius Elbow |

| Short Radius Elbow |

Center to Center. P |

Back to Face K |

| 1/2 |

21.3 |

76.2 |

47.8 |

- |

- |

| 3/4 |

26.7 |

76.2 |

50.8 |

- |

- |

| 1 |

33.4 |

76.2 |

55.6 |

50.8 |

41.1 |

| 1-1/4 |

42.2 |

95.2 |

69.8 |

63.5 |

52.3 |

| 1-1/2 |

48.3 |

114.3 |

82.6 |

76.2 |

62.0 |

| 2 |

60.3 |

152.4 |

106.4 |

101.6 |

81.0 |

| 2-1/2 |

73.0 |

109.5 |

131.8 |

127.0 |

100.1 |

| 3 |

88.9 |

228.6 |

158.8 |

152.4 |

120.7 |

| 3-1/2 |

101.6 |

266.7 |

184.2 |

177.8 |

139.7 |

| 4 |

114.3 |

304.8 |

209.6 |

203.2 |

158.8 |

| 5 |

141.3 |

381.0 |

261.9 |

254.0 |

196.9 |

| 6 |

168.3 |

457.2 |

312.7 |

304.8 |

236.5 |

| 8 |

219.1 |

609.6 |

414.3 |

406.4 |

312.7 |

| 10 |

273.1 |

762.0 |

517.7 |

508.0 |

390.7 |

| 12 |

323.9 |

914.4 |

619.3 |

609.6 |

466.9 |

| 14 |

355.6 |

1066.8 |

711.2 |

711.2 |

533.4 |

| 16 |

406.4 |

1219.2 |

812.8 |

812.8 |

609.6 |

| 18 |

457.2 |

1371.6 |

914.4 |

914.4 |

685.8 |

| 20 |

508.0 |

1524.0 |

1016.0 |

1016.0 |

762.0 |

| 22 |

558.8 |

1676.4 |

1117.6 |

1117.6 |

838.2 |

| 24 |

609.6 |

1828.8 |

1219.2 |

1219.2 |

914.4 |

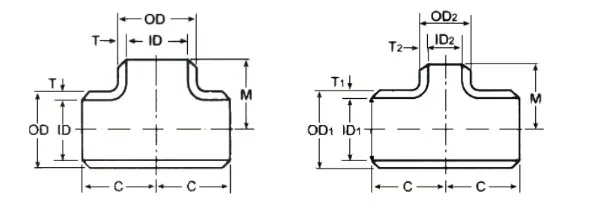

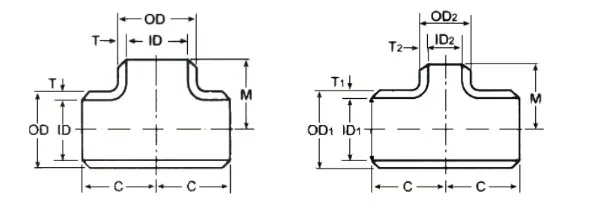

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 1/2 x 1/2 |

21.3 |

21.3 |

25.4 |

25.4 |

| 1/2 x 3/8 |

|

17.1 |

|

25.4 |

| 1/2 x 1/4 |

|

13.7 |

|

25.4 |

| 3/4 x 3/4 |

26.7 |

26.7 |

28.4 |

28.4 |

| 3/4 x 1/2 |

|

21.3 |

|

28.4 |

| 3/4 x 3/8 |

|

17.1 |

|

28.4 |

| 1 x 1 |

33.4 |

33.4 |

38.1 |

38.1 |

| 1 x 3/4 |

|

26.7 |

|

38.1 |

| 1 x 1/2 |

|

21.3 |

|

38.1 |

| 1-1/4 x 1-1/4 |

42.2 |

42.2 |

47.8 |

47.8 |

| 1-1/4 x 1 |

|

33.4 |

|

47.8 |

| 1-1/4 x 3/4 |

|

26.7 |

|

47.8 |

| 1-1/4 x 1/2 |

|

21.3 |

|

47.8 |

| 1-1/2 x 1-1/2 |

48.3 |

48.3 |

57.2 |

57.2 |

| 1-1/2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 1-1/2 x 1 |

|

33.4 |

|

57.2 |

| 1-1/2 x 3/4 |

|

26.7 |

|

57.2 |

| 1-1/2 x 1/2 |

|

21.3 |

|

57.2 |

| 2 x 2 |

60.3 |

60.3 |

63.5 |

63.5 |

| 2 x 1-1/2 |

|

48.3 |

|

60.5 |

| 2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 2 x 1 |

|

33.4 |

|

50.8 |

| 2 x 3/4 |

|

26.7 |

|

44.4 |

| 2 x 1/2* |

|

21.3 |

|

|

| 2-1/2 x 2-1/2 |

73.0 |

73.0 |

76.2 |

76.2 |

| 2-1/2 x 2 |

|

60.3 |

|

69.8 |

| 2-1/2 x 1-1/2 |

|

48.3 |

|

66.5 |

| 2-1/2 x 1-1/4 |

|

42.2 |

|

63.5 |

| 2-1/2 x 1 |

|

33.4 |

|

57.2 |

| 3 x 3 |

88.9 |

88.9 |

85.9 |

85.9 |

| 3 x 2-1/2 |

|

73.0 |

|

82.6 |

| 3 x 2 |

|

60.3 |

|

76.2 |

| 3 x 1-1/2 |

|

48.3 |

|

73.2 |

| 3 x 1-1/4 |

|

42.2 |

|

69.8 |

| 3 x 1* |

|

33.4 |

|

|

| 3-1/2 x 3-1/2 |

101.6 |

101.6 |

95.2 |

95.2 |

| 3-1/2 x 3 |

|

88.9 |

|

91.9 |

| 3-1/2 x 2-1/2 |

|

73.0 |

|

88.9 |

| 3-1/2 x 2 |

|

60.3 |

|

82.6 |

| 3-1/2 x 1-1/2 |

|

48.3 |

|

79.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 4 x 4 |

114.3 |

114.3 |

104.6 |

104.6 |

| 4 x 3-1/2 |

|

101.6 |

|

101.6 |

| 4 x 3 |

|

88.9 |

|

98.6 |

| 4 x 2-1/2 |

|

73.0 |

|

95.2 |

| 4 x 2 |

|

60.3 |

|

88.9 |

| 4 x 1-1/2 |

|

48.3 |

|

85.9 |

| 4 x 1-1/4 |

|

42.2 |

|

|

| 4 x 1* |

|

33.5 |

|

|

| 5 x 5 |

141.3 |

141.3 |

124.0 |

124.0 |

| 5 x 4 |

|

114.3 |

|

117.3 |

| 5 x 3-1/2 |

|

101.6 |

|

114.3 |

| 5 x 3 |

|

88.9 |

|

111.3 |

| 5 x 2-1/2 |

|

73.0 |

|

108.0 |

| 5 x 2 |

|

60.3 |

|

104.6 |

| 5 x 1-1/2* |

|

48.3 |

|

|

| 6 x 6 |

168.3 |

168.3 |

142.7 |

142.7 |

| 6 x 5 |

|

141.3 |

|

136.7 |

| 6 x 4 |

|

114.3 |

|

130.0 |

| 6 x 3-1/2 |

|

101.6 |

|

127.0 |

| 6 x 3 |

|

88.9 |

|

124.0 |

| 6 x 2-1/2 |

|

73.0 |

|

120.6 |

| 6 x 2* |

|

60.3 |

|

|

| 8 x 8 |

19.1 |

219.1 |

177.8 |

177.8 |

| 8 x 6 |

|

168.3 |

|

168.1 |

| 8 x 5 |

|

141.3 |

|

162.1 |

| 8 x 4 |

|

114.3 |

|

155.4 |

| 8 x 3-1/2 |

|

101.6 |

|

152.4 |

| 8 x 3* |

|

88.9 |

|

|

| 10 x 10 |

273.1 |

273.1 |

215.9 |

215.9 |

| 10 x 8 |

|

219.1 |

|

203.2 |

| 10 x 6 |

|

168.3 |

|

193.5 |

| 10 x 5 |

|

141.3 |

|

190.5 |

| 10 x 4 |

|

114.3 |

|

184.2 |

| 12 x 12 |

323.9 |

323.9 |

254.0 |

254.0 |

| 12 x 10 |

|

273.1 |

|

241.3 |

| 12 x 8 |

|

219.1 |

|

228.6 |

| 12 x 6 |

|

168.3 |

|

218.9 |

| 12 x 5 |

|

141.3 |

|

215.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 14 x 14 |

355.6 |

355.6 |

279.4 |

279.4 |

| 14 x 12 |

|

323.9 |

|

269.7 |

| 14 x 10 |

|

273.1 |

|

257.0 |

| 14 x 8 |

|

219.1 |

|

247.6 |

| 14 x 6 |

|

168.3 |

|

238.3 |

| 16 x 16 |

406.4 |

406.4 |

304.8 |

304.8 |

| 16 x 14 |

|

355.6 |

|

304.8 |

| 16 x 12 |

|

323.9 |

|

295.1 |

| 16 x 10 |

|

273.1 |

|

282.4 |

| 16 x 8 |

|

219.1 |

|

373.0 |

| 16 x 6 |

|

168.3 |

|

263.7 |

| 18 x 18 |

457.2 |

457.2 |

342.9 |

342.9 |

| 18 x 16 |

|

406.4 |

|

330.2 |

| 18 x 14 |

|

355.6 |

|

330.2 |

| 18 x 12 |

|

323.9 |

|

320.5 |

| 18 x 10 |

|

273.1 |

|

307.8 |

| 18 x 8 |

|

219.1 |

|

298.4 |

| 20 x 20 |

508.0 |

508.0 |

381.0 |

381.0 |

| 20 x 18 |

|

457.2 |

|

369.3 |

| 20 x 16 |

|

406.4 |

|

355.6 |

| 20 x 14 |

|

355.6 |

|

355.6 |

| 20 x 12 |

|

323.9 |

|

345.9 |

| 20 x 10 |

|

273.1 |

|

333.2 |

| 20 x 8 |

|

219.1 |

|

323.8 |

| 22 x 22 |

558.8 |

558.8 |

419.1 |

419.1 |

| 22 x 20 |

|

508.0 |

|

406.4 |

| 22 x 18 |

|

457.2 |

|

393.7 |

| 22 x 16 |

|

406.4 |

|

381.0 |

| 22 x 14 |

|

355.6 |

|

381.0 |

| 22 x 12 |

|

323.9 |

|

371.3 |

| 22 x 10 |

|

273.1 |

|

358.6 |

| 24 x 24 |

609.6 |

609.6 |

431.8 |

431.8 |

| 24 x 22 |

|

558.8 |

|

431.8 |

| 24 x 20 |

|

508.0 |

|

431.8 |

| 24 x 18 |

|

457.2 |

|

419.1 |

| 24 x 16 |

|

406.4 |

|

406.4 |

| 24 x 14 |

|

355.6 |

|

406.4 |

| 24 x 12 |

|

323.9 |

|

396.7 |

| 24 x 10 |

|

273.1 |

|

384.0 |

| 26 x 26 |

660.4 |

660.4 |

495.3 |

495.3 |

| 26 x 24 |

|

609.6 |

|

482.6 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 26 x 22 |

|

558.8 |

|

469.9 |

| 26 x 20 |

|

508.0 |

|

457.2 |

| 26 x 18 |

|

457.2 |

|

444.5 |

| 26 x 16 |

|

406.4 |

|

431.8 |

| 26 x 14 |

|

355.6 |

|

431.8 |

| 26 x 12 |

|

323.1 |

|

422.1 |

| 28 x 28 |

711.2 |

711.2 |

520.7 |

520.7 |

| 28 x 26 |

|

660.4 |

|

520.7 |

| 28 x 24 |

|

609.6 |

|

508.0 |

| 28 x 22 |

|

558.8 |

|

495.3 |

| 28 x 20 |

|

508.0 |

|

482.6 |

| 28 x 18 |

|

457.2 |

|

469.9 |

| 28 x 16 |

|

406.4 |

|

457.2 |

| 28 x 14 |

|

355.6 |

|

457.2 |

| 28 x 12 |

|

323.1 |

|

447.5 |

| 30 x 30 |

762.0 |

762.0 |

558.8 |

558.8 |

| 30 x 28 |

|

711.2 |

|

546.1 |

| 30 x 26 |

|

660.4 |

|

546.1 |

| 30 x 24 |

|

609.6 |

|

533.4 |

| 30 x 22 |

|

558.8 |

|

520.7 |

| 30 x 20 |

|

508.0 |

|

508.0 |

| 30 x 18 |

|

457.2 |

|

495.3 |

| 30 x 16 |

|

406.4 |

|

482.6 |

| 30 x 14 |

|

355.6 |

|

482.6 |

| 30 x 12 |

|

323.9 |

|

472.6 |

| 30 x 10 |

|

273.1 |

|

460.2 |

| 32 x 32 |

812.8 |

812.8 |

596.9 |

596.9 |

| 32 x 30 |

|

762.0 |

|

584.2 |

| 32 x 28 |

|

711.2 |

|

571.5 |

| 32 x 26 |

|

660.4 |

|

571.5 |

| 32 x 24 |

|

609.6 |

|

558.8 |

| 32 x 22 |

|

558.8 |

|

546.1 |

| 32 x 20 |

|

508.0 |

|

533.4 |

| 32 x 18 |

|

457.2 |

|

520.7 |

| 32 x 16 |

|

406.4 |

|

508.0 |

| 32 x 14 |

|

355.6 |

|

508.0 |

| 34 x 34 |

863.6 |

863.6 |

635.0 |

635.0 |

| 34 x 32 |

|

812.8 |

|

622.3 |

| 34 x 30 |

|

762.0 |

|

609.6 |

| 34 x 28 |

|

711.2 |

|

596.9 |

| 34 x 26 |

|

660.4 |

|

596.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 34 x 24 |

|

609.6 |

|

584.2 |

| 34 x 22 |

|

558.8 |

|

571.5 |

| 34 x 20 |

|

508.0 |

|

558.8 |

| 34 x 18 |

|

457.2 |

|

546.1 |

| 34 x 16 |

|

406.4 |

|

533.4 |

| 36 x 36 |

914.4 |

914.4 |

673.1 |

673.1 |

| 36 x 34 |

|

863.6 |

|

660.4 |

| 36 x 32 |

|

812.8 |

|

647.7 |

| 36 x 30 |

|

762.0 |

|

635.0 |

| 36 x 28 |

|

711.2 |

|

622.3 |

| 36 x 26 |

|

660.4 |

|

622.3 |

| 36 x 24 |

|

609.6 |

|

609.6 |

| 36 x 22 |

|

558.8 |

|

596.9 |

| 36 x 20 |

|

508.0 |

|

584.2 |

| 36 x 18 |

|

457.2 |

|

571.5 |

| 36 x 16 |

|

406.4 |

|

558.8 |

| 38 x 38 |

965.2 |

965.2 |

711.2 |

711.2 |

| 38 x 36 |

|

914.4 |

|

711.2 |

| 38 x 34 |

|

863.6 |

|

698.5 |

| 38 x 32 |

|

812.8 |

|

685.8 |

| 38 x 30 |

|

762.0 |

|

673.1 |

| 38 x 28 |

|

711.2 |

|

647.7 |

| 38 x 26 |

|

660.4 |

|

647.7 |

| 38 x 24 |

|

609.6 |

|

635.0 |

| 38 x 22 |

|

558.8 |

|

622.3 |

| 38 x 20 |

|

508.0 |

|

609.6 |

| 38 x 18 |

|

457.2 |

|

596.9 |

| 40 x 40 |

1016.0 |

1016.0 |

749.3 |

749.3 |

| 40 x 38 |

|

965.2 |

|

749.3 |

| 40 x 36 |

|

914.4 |

|

736.6 |

| 40 x 34 |

|

863.6 |

|

723.9 |

| 40 x 32 |

|

812.8 |

|

711.2 |

| 40 x 30 |

|

762.0 |

|

698.5 |

| 40 x 28 |

|

711.2 |

|

673.1 |

| 40 x 26 |

|

660.4 |

|

673.1 |

| 40 x 24 |

|

609.6 |

|

660.4 |

| 40 x 22 |

|

558.8 |

|

647.7 |

| 40 x 20 |

|

508.0 |

|

635.0 |

| 40 x 18 |

|

457.2 |

|

622.3 |

| 42 x 42 |

1066.8 |

1066.8 |

762.0 |

711.2 |

| 42 x 40 |

|

1016.0 |

|

711.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 42 x 38 |

|

965.2 |

|

711.2 |

| 42 x 36 |

|

914.4 |

|

711.2 |

| 42 x 34 |

|

863.6 |

|

711.2 |

| 42 x 32 |

|

812.8 |

|

711.2 |

| 42 x 30 |

|

762.0 |

|

711.2 |

| 42 x 28 |

1066.8 |

711.2 |

762.0 |

698.5 |

| 42 x 26 |

|

660.4 |

|

698.5 |

| 42 x 24 |

|

609.6 |

|

660.4 |

| 42 x 22 |

|

558.8 |

|

660.4 |

| 42 x 20 |

|

508.0 |

|

660.4 |

| 42 x 18 |

|

457.2 |

|

647.7 |

| 42 x 16 |

|

406.4 |

|

635.0 |

| 44 x 44 |

1117.6 |

1117.6 |

812.8 |

762.0 |

| 44 x 42 |

|

1066.8 |

|

762.0 |

| 44 x 40 |

|

1016.0 |

|

749.3 |

| 44 x 38 |

|

965.2 |

|

736.6 |

| 44 x 36 |

|

914.4 |

|

723.9 |

| 44 x 34 |

|

863.6 |

|

723.9 |

| 44 x 32 |

|

812.8 |

|

711.2 |

| 44 x 30 |

|

762.0 |

|

711.2 |

| 44 x 28 |

|

711.2 |

|

698.5 |

| 44 x 26 |

|

660.4 |

|

698.5 |

| 44 x 24 |

|

609.6 |

|

698.5 |

| 44 x 22 |

|

558.8 |

|

685.8 |

| 44 x 20 |

|

508.0 |

|

685.8 |

| 46 x 46 |

1168.4 |

1168.4 |

850.9 |

800.1 |

| 46 x 44 |

|

1117.6 |

|

800.1 |

| 46 x 42 |

|

1066.8 |

|

787.4 |

| 46 x 40 |

|

1016.0 |

|

774.7 |

| 46 x 38 |

|

965.2 |

|

762.0 |

| 46 x 36 |

|

914.4 |

|

762.0 |

| 46 x 34 |

|

863.6 |

|

749.3 |

| 46 x 32 |

|

812.8 |

|

749.3 |

| 46 x 30 |

|

762.0 |

|

736.6 |

| 46 x 28 |

|

711.2 |

|

736.6 |

| 46 x 26 |

|

660.4 |

|

736.6 |

| 46 x 24 |

|

609.6 |

|

723.9 |

| 46 x 20* |

|

508.0 |

|

723.9 |

| 48 x 48 |

1219.2 |

1219.2 |

889.0 |

838.2 |

| 48 x 46 |

|

1168.4 |

|

838.2 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

1219.2 |

812.8 |

889.0 |

787.4 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

|

812.8 |

|

787.4 |

| 48 x 30 |

|

762.0 |

|

762.0 |

| 48 x 28 |

|

711.2 |

|

762.0 |

| 48 x 26 |

|

660.4 |

|

762.0 |

| 48 x 24 |

|

609.6 |

|

736.6 |

| 48 x 22 |

|

558.8 |

|

736.6 |

| 52 x 52* |

1320.8 |

1320.8 |

965.2 |

914.4 |

| 52 x 48* |

|

1219.2 |

|

863.6 |

| 52 x 44* |

|

1117.6 |

|

812.8 |

| 52 x 40* |

|

1016.0 |

|

762.0 |

| 54 x 54* |

1371.6 |

1371.6 |

1003.3 |

952.5 |

| 54 x 52* |

|

1320.8 |

|

914.4 |

| 54 x 48* |

|

1219.2 |

|

863.6 |

| 54 x 44* |

|

1117.6 |

|

863.6 |

| 54 x 40* |

|

1016.0 |

|

812.8 |

| 54 x 28* |

|

711.2 |

|

787.4 |

| 54 x 20* |

|

508.0 |

|

787.4 |

| 56 x 56* |

1422.4 |

1422.4 |

1041.4 |

965.2 |

| 56 x 52* |

|

1320.8 |

|

914.4 |

| 56 x 48* |

|

1219.2 |

|

863.6 |

| 56 x 44* |

|

1117.6 |

|

812.8 |

| 56 x 40* |

|

1016.0 |

|

812.8 |

| 56 x 28* |

|

711.2 |

|

812.8 |

| 56 x 20* |

|

508.0 |

|

812.8 |

| 60 x 60* |

1524.0 |

1524.0 |

1117.6 |

1016.0 |

| 60 x 56* |

|

1422.4 |

|

965.2 |

| 60 x 52* |

|

1320.8 |

|

914.4 |

| 60 x 48* |

|

1219.2 |

|

863.6 |

| 60 x 40* |

|

1016.0 |

|

863.6 |

| 60 x 28* |

|

711.2 |

|

863.6 |

| 60 x 20* |

|

508.0 |

|

863.6 |

| 64 x 64* |

1626.0 |

1626.0 |

1194.0 |

1092.0 |

| 64 x 60* |

|

1524.0 |

|

1067.0 |

| 64 x 56* |

|

1422.0 |

|

1016.0 |

| 64 x 52* |

|

1321.0 |

|

965.0 |

| 64 x 48* |

|

1219.0 |

|

914 |

| 66 x 66* |

1676.4 |

1676.4 |

1219.2 |

1066.8 |

| 68 x 68* |

1727.0 |

1727.0 |

1270.0 |

1168.0 |

| 68 x 64* |

|

1626.0 |

|

1143.0 |

| 68 x 60* |

|

1524.0 |

|

1118.0 |

| 68 x 56* |

|

1422.0 |

|

1067.0 |

| 68 x 52* |

|

1321.0 |

|

1016.0 |

| 68 x 48* |

|

1219.0 |

|

965.0 |

| 72 x 72* |

1829.0 |

1829.0 |

1320.0 |

1245.0 |

| 72 x 68* |

|

1727.0 |

|

1219.0 |

| 72 x 64* |

|

1626.0 |

|

1194.0 |

| 72 x 60* |

|

1524.0 |

|

1168.0 |

| 72 x 56* |

1829.0 |

1422.0 |

1320.0 |

1118.0 |

| 72 x 52* |

|

1321.0 |

|

1067.0 |

| 72 x 48* |

|

1219.0 |

|

1016.0 |

| 76 x 76* |

1930.0 |

1930.0 |

1422.0 |

1320.0 |

| 76 x 72* |

|

1829.0 |

|

1295.0 |

| 76 x 68* |

|

1727.0 |

|

1270.0 |

| 76 x 64* |

|

1626.0 |

|

1245.0 |

| 76 x 60* |

|

1524.0 |

|

1219.0 |

| 76 x 56* |

|

1422.0 |

|

1168.0 |

| 76 x 52* |

|

1321.0 |

|

1118.0 |

| 76 x 48* |

|

1219.0 |

|

1067.0 |

| 80 x 80* |

2032.0 |

2032.0 |

1499.0 |

1397.0 |

| 80 x 76* |

|

1930.0 |

|

1372.0 |

| 80 x 72* |

|

1829.0 |

|

1346.0 |

| 80 x 68* |

|

1727.0 |

|

1321.0 |

| 80 x 64* |

|

1626.0 |

|

1295.0 |

| 80 x 60* |

|

1524.0 |

|

1270.0 |

| 80 x 56* |

|

1422.0 |

|

1219.0 |

| 80 x 52* |

|

1321.0 |

|

1168.0 |

| 80 x 48* |

|

1219.0 |

|

1118.0 |

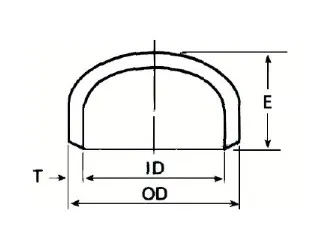

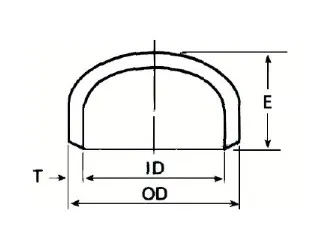

ANSI B16.9 / MSS SP-75 Cap Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel D |

Center to End E |

| 1/2 |

21.3 |

25.4 |

| 3/4 |

26.7 |

25.4 |

| 1 |

33.4 |

38.1 |

| 1-1/4 |

42.2 |

38.1 |

| 1-1/2 |

48.3 |

38.1 |

| 2 |

60.3 |

38.1 |

| 2-1/2 |

73.0 |

38.1 |

| 3 |

88.9 |

50.8 |

| 3-1/2 |

101.6 |

63.5 |

| 4 |

114.3 |

63.5 |

| 5 |

141.3 |

76.2 |

| 6 |

168.3 |

88.9 |

| 8 |

219.1 |

101.6 |

| 10 |

273.1 |

127.0 |

| 12 |

323.9 |

152.4 |

| 14 |

355.6 |

165.1 |

| 16 |

406.4 |

177.8 |

| 18 |

457.2 |

203.2 |

| 20 |

508.0 |

228.6 |

| 22 |

558.8 |

254.0 |

| 24 |

609.6 |

266.7 |

| 26 |

660.4 |

266.7 |

| 28 |

711.2 |

266.7 |

| 30 |

762.0 |

266.7 |

| 32 |

812.8 |

266.7 |

| 34 |

863.6 |

266.7 |

| 36 |

914.4 |

266.7 |

| 38 |

965.2 |

304.8 |

| 40 |

1016.0 |

304.8 |

| 42 |

1066.8 |

304.8 |

| 44 |

1117.6 |

342.9 |

| 46 |

1168.4 |

342.9 |

| 48 |

1219.2 |

342.9 |

ANSI B36.19M Wall Thickness Schedule Dimension Chart (mm, kg)

| Nominal Pipe Size |

Outside Diameter |

Nominal Wall Thickness |

| A |

B |

JIS |

ANSI |

Sch 5S |

Sch 10S |

Sch 20S |

GS |

Sch 10 |

LG (7.9) |

Sch 20 |

Sch 30 |

STD |

Sch 40 |

Sch 60 |

XS |

Sch 80 |

Sch 100 |

Sch 120 |

Sch 140 |

Sch 160 |

XXS |

| 8 |

1/4 |

13.8 |

13.7 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.2) |

2.2 |

2.4 |

(3.0) |

3.0 |

- |

- |

- |

- |

- |

| 10 |

3/8 |

17.3 |

17.1 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.3) |

2.3 |

2.8 |

(3.2) |

3.2 |

- |

- |

- |

- |

- |

| 15 |

1/2 |

21.7 |

21.3 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.8) |

2.8 |

3.2 |

(3.7) |

3.7 |

- |

- |

- |

4.7 |

7.5 |

| 20 |

3/4 |

27.2 |

26.7 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.9) |

2.9 |

3.4 |

(3.9) |

3.9 |

- |

- |

- |

5.5 |

7.8 |

| 25 |

1 |

34.0 |

33.4 |

1.65 |

2.8 |

3.0 |

3.2 |

- |

- |

- |

- |

(3.4) |

3.4 |

3.9 |

(4.5) |

4.5 |

- |

- |

- |

6.4 |

9.1 |

| 32 |

1-1/4 |

42.7 |

42.2 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.6) |

3.6 |

4.5 |

(4.9) |

4.9 |

- |

- |

- |

6.4 |

9.7 |

| 40 |

1-1/2 |

48.6 |

48.3 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.7) |

3.7 |

4.5 |

(5.1) |

5.1 |

- |

- |

- |

7.1 |

10.2 |

| 50 |

2 |

60.5 |

60.3 |

1.65 |

2.8 |

3.5 |

3.8 |

- |

- |

- |

- |

(3.9) |

3.9 |

4.9 |

(5.5) |

5.5 |

- |

- |

- |

8.7 |

11.1 |

| 65 |

2-1/2 |

76.3 |

73.0 |

2.1 |

3.0 |

3.5 |

4.2 |

- |

- |

- |

- |

(5.2) |

5.2 |

6.0 |

(7.0) |

7.0 |

- |

- |

- |

9.5 |

14.0 |

| 80 |

3 |

89.1 |

88.9 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.5) |

5.5 |

6.6 |

(7.6) |

7.6 |

- |

- |

- |

11.1 |

15.2 |

| 90 |

3-1/2 |

101.6 |

101.6 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.7) |

5.7 |

7.0 |

(8.1) |

8.1 |

- |

- |

- |

12.7 |

- |

| 100 |

4 |

114.3 |

114.3 |

2.1 |

3.0 |

4.0 |

4.5 |

- |

- |

- |

- |

(6.0) |

6.0 |

7.1 |

(8.6) |

8.6 |

- |

11.1 |

- |

13.5 |

17.1 |

| 125 |

5 |

139.8 |

141.3 |

2.8 |

3.4 |

5.0 |

4.5 |

- |

- |

- |

- |

(6.6) |

6.6 |

8.1 |

(9.5) |

9.5 |

- |

12.7 |

- |

15.9 |

19.0 |

| 150 |

6 |

165.2 |

168.3 |

2.8 |

3.4 |

5.0 |

5.0 |

- |

5.0** |

- |

- |

(7.1) |

7.1 |

9.3 |

(11.0) |

11.0 |

- |

14.3 |

- |

18.2 |

21.9 |

| 175 |

7 |

190.7 |

- |

- |

- |

- |

5.3 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 200 |

8 |

216.3 |

219.1 |

2.8 |

3.8 |

6.5 |

5.8 |

- |

5.8** |

6.4 |

7.0 |

(8.2) |

8.2 |

10.3 |

(12.7) |

12.7 |

15.1 |

18.2 |

20.6 |

23.0 |

22.2 |

| 225 |

9 |

241.8 |

- |

- |

- |

- |

6.2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 250 |

10 |

267.4 |

273.1 |

3.4 |

4.2 |

6.5 |

6.6 |

- |

6.6** |

6.4 |

7.8 |

(9.3) |

9.3 |

12.7 |

12.7 |

15.1 |

18.3 |

21.4 |

25.4 |

28.6 |

25.4 |

| 300 |

12 |

318.5 |

323.9 |

4.0 |

4.6 |

6.5 |

6.9 |

- |

6.9** |

6.4 |

8.4 |

9.5 |

10.3 |

14.3 |

12.7 |

17.4 |

21.4 |

25.4 |

28.6 |

33.3 |

25.4 |

| 350 |

14 |

355.6 |

355.6 |

4.0 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

11.1 |

15.1 |

12.7 |

19.0 |

23.8 |

27.8 |

31.8 |

35.7 |

- |

| 400 |

16 |

406.4 |

406.4 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

12.7 |

16.7 |

12.7 |

21.4 |

26.2 |

30.9 |

36.5 |

40.5 |

- |

| 450 |

18 |

457.2 |

457.2 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

11.1 |

9.5 |

14.3 |

19.0 |

12.7 |

23.8 |

29.4 |

34.9 |

39.7 |

45.2 |

- |

| 500 |

20 |

508.0 |

508.0 |

4.8 |

5.5 |

7.9 |

7.9 |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

15.1 |

20.6 |

12.7 |

26.2 |

32.5 |

38.1 |

44.4 |

50.0 |

- |

| 550 |

22 |

558.8 |

558.8 |

4.8 |

5.5 |

- |

- |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

- |

22.2 |

12.7 |

28.6 |

34.9 |

41.3 |

47.6 |

54.0 |

- |

| 600 |

24 |

609.6 |

609.6 |

5.5 |

6.4 |

- |

- |

6.4 |

7.9 |

9.5 |

14.3 |

9.5 |

17.5 |

24.6 |

12.7 |

31.0 |

38.9 |

46.0 |

52.4 |

59.5 |

- |

| 650 |

26 |

660.4 |

660.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 700 |

28 |

711.2 |

711.2 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 750 |

30 |

762.0 |

762.0 |

6.4 |

7.9 |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 800 |

32 |

812.8 |

812.8 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 850 |

34 |

863.6 |

863.6 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 900 |

36 |

914.4 |

914.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

19.1 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 950 |

38 |

965.2 |

965.2 |

- |

- |

- |

- |

- |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1000 |

40 |

1016.0 |

1016.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1050 |

42 |

1066.8 |

1066.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1100 |

44 |

1117.6 |

1117.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1150 |

46 |

1168.4 |

1168.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1200 |

48 |

1219.2 |

1219.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1250 |

50 |

1270.0 |

1270.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1300 |

52 |

1320.8 |

1320.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1350 |

54 |

1371.6 |

1371.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1400 |

56 |

1422.4 |

1422.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1450 |

58 |

1473.2 |

1473.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1500 |

60 |

1524.0 |

1524.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1600 |

64 |

1626.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1700 |

68 |

1727.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1800 |

72 |

1829.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1900 |

76 |

1932.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2000 |

80 |

2032.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions in accordance with JIS G3448, JIS G3455, JIS G3454, JIS G3459, ANSI B36.10M