ANSI B16.9 Alloy Steel ButtWeld Fittings Weight, Dimensions Chart in mm, kg, PDF online

A buttweld fitting is a pipe fitting that is weldable that allows for change of direction of flow, to

branch off, reduces pipe size or attach additional equipment. A buttweld fitting is produced by the

process of hot or cold forming, which means that it is bended and moulded to the correct shape. They are

also heat treated to remove residual stresses and to achieve special mechanical properties. The ends of

buttweld fittings have to be bevelled and the exact shape and form of the bevel depends upon the wall

thickness of the pipe it is being attached to. The material of a buttweld fitting can be any one of a

number of exotic materials such as super duplex, nickel alloy or 6% Molybdenum. The most of the time,

the

material of the fitting is the same as the pipe system that it is welded to. Weight and Dimensions Chart

PDF is given below.

- Alloy Steel Buttweld Fitting: Alloy steel butt weld fittings are components used in piping

systems to connect and change the direction of pipes or tubes. These fittings are made from alloy

steel materials, which provide enhanced strength, corrosion resistance, and other properties

compared to standard carbon steel fittings. Alloy steel butt weld fittings are typically made from

various alloy steel grades, including but not limited to Chrome-Moly Alloys(contain chromium and

molybdenum), Stainless Steel Alloys, Low-Alloy Steels and other Alloy Steels for specific

requirements. Alloy steel butt weld fittings are available in a wide range of sizes, from small

diameters for low-pressure applications to large diameters for high-pressure systems. For detailed

reference, refer to the Alloy Steel Buttweld Fittings Weight and Dimensions Chart PDF, where

dimensions and weights are given in mm and kg respectively.

Features:

- Chrome-Moly Alloys offer high-temperature strength and corrosion resistance.

- Stainless steel Alloys provide excellent corrosion resistance.

- Low-Alloy Steels offer good strength and toughness while maintaining weldability and

corrosion resistance.

Applications:

Alloy steel butt weld fittings are used in a wide range of industries and

applications, including oil and gas, petrochemical, power generation, chemical processing, water

treatment, and more. They are suitable for high-pressure and high-temperature environments, making

them ideal for demanding conditions. Different applications demand different weight and dimensions

to be used. Alloy Steel Buttweld Fittings Dimensions Chart given in mm, kg gives all the

information. The wide variety of implementations shows the strength of the buttweld fitting and how

often this specific type of fitting is used.

Specifications of Buttweld Fittings

Alloy steel butt weld fittings must adhere to specific industry standards and specifications, such as

ASTM (American Society for Testing and Materials) standards, ASME (American Society of Mechanical

Engineers) standards, and ANSI (American National Standards Institute) standards. These standards define

material grades, dimensions, and testing requirements. The dimensional standard of the buttweld fittings

we supply are in accordance with the ANSI B16.9, MSS SP43 and MSS SP75. All the specifications of

buttweld

fittings are mentioned in the Dimensions Chart below.

Types of Alloy Steel Buttweld fitting:

The types of Alloy Steel Buttweld fitting are:

- Elbows

- Tees

- Reducers

- Cap

- Stub End

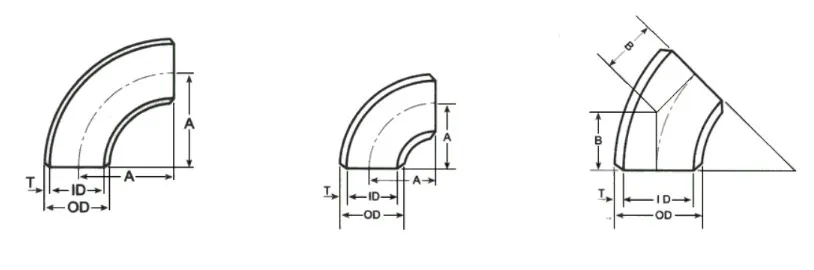

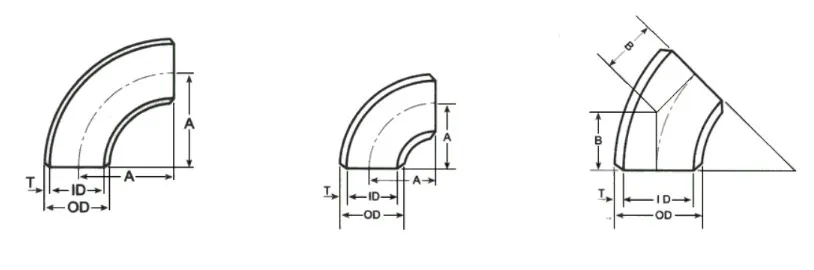

ANSI B16.9/B16.28 90°/45° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel(OD) |

Center to End |

| Long Radius Elbow |

Short Radius Elbow |

| 90 degree. A |

45 degree B |

90 degree A |

| 1/2 |

21.3 |

38.1 |

15.7 |

- |

| 3/4 |

26.7 |

38.1 |

19.1 |

- |

| 1 |

33.4 |

38.1 |

22.4 |

25.4 |

| 1-1/4 |

42.2 |

47.8 |

25.4 |

31.8 |

| 1-1/2 |

48.3 |

57.2 |

28.4 |

38.1 |

| 2 |

60.3 |

76.2 |

35.1 |

50.8 |

| 2-1/2 |

73.0 |

95.2 |

44.4 |

63.5 |

| 3 |

88.9 |

114.3 |

50.8 |

76.2 |

| 3-1/2 |

101.6 |

133.4 |

57.2 |

88.9 |

| 4 |

114.3 |

152.4 |

63.5 |

101.6 |

| 5 |

141.3 |

190.5 |

79.2 |

127.0 |

| 6 |

168.3 |

228.6 |

95.2 |

152.4 |

| 8 |

219.1 |

304.8 |

127.0 |

203.2 |

| 10 |

273.1 |

381.0 |

158.8 |

254.0 |

| 12 |

323.9 |

457.2 |

190.5 |

304.8 |

| 14 |

355.6 |

533.4 |

222.2 |

355.6 |

| 16 |

406.4 |

609.6 |

254.0 |

406.4 |

| 18 |

457.2 |

685.8 |

285.8 |

457.2 |

| 20 |

508.0 |

762.0 |

317.5 |

508.0 |

| 22 |

558.8 |

838.2 |

342.9 |

558.8 |

| 24 |

609.6 |

914.4 |

381.0 |

609.6 |

| 26 |

660.4 |

990.6 |

406.4 |

660.4 |

| 28 |

711.2 |

1066.8 |

438.2 |

711.2 |

| 30 |

762.0 |

1143.0 |

469.9 |

762.0 |

| 32 |

812.8 |

1219.2 |

501.6 |

812.8 |

| 34 |

863.6 |

1295.4 |

533.4 |

863.6 |

| 36 |

914.4 |

1371.6 |

565.2 |

914.4 |

| 38 |

965.2 |

1447.8 |

599.9 |

- |

| 40 |

1016.0 |

1524.0 |

632.0 |

1016.0 |

| 42 |

1066.8 |

1600.2 |

660.4 |

1066.8 |

| 44 |

1117.6 |

1676.4 |

695.5 |

1117.6 |

| 46 |

1168.4 |

1752.6 |

726.9 |

- |

| 48 |

1219.2 |

1828.8 |

759.0 |

1219.2 |

| 52* |

1320.8 |

- |

- |

1320.8 |

| 54* |

1371.6 |

2057.4 |

852.2 |

1371.6 |

| 56* |

1422.4 |

2133.6 |

883.8 |

1422.4 |

| 60* |

1524.0 |

2286.0 |

946.9 |

1524.0 |

| 66* |

1676.4 |

2514.6 |

1041.6 |

- |

| 68* |

1727.0 |

2591 |

1073 |

1727 |

| 72* |

1829.0 |

2743 |

1137 |

1829 |

| 76* |

1930.0 |

2896 |

1199 |

1930 |

| 80* |

2032.0 |

3048 |

1263 |

2032 |

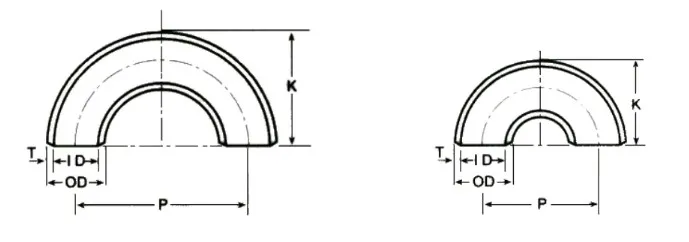

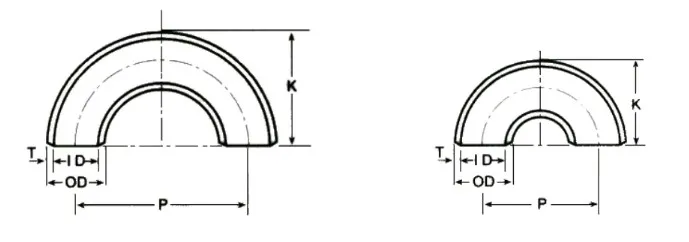

ANSI B16.9/B16.28 180° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel OD |

Long Radius Elbow |

Short Radius Elbow |

| Short Radius Elbow |

Center to Center. P |

Back to Face K |

| 1/2 |

21.3 |

76.2 |

47.8 |

- |

- |

| 3/4 |

26.7 |

76.2 |

50.8 |

- |

- |

| 1 |

33.4 |

76.2 |

55.6 |

50.8 |

41.1 |

| 1-1/4 |

42.2 |

95.2 |

69.8 |

63.5 |

52.3 |

| 1-1/2 |

48.3 |

114.3 |

82.6 |

76.2 |

62.0 |

| 2 |

60.3 |

152.4 |

106.4 |

101.6 |

81.0 |

| 2-1/2 |

73.0 |

109.5 |

131.8 |

127.0 |

100.1 |

| 3 |

88.9 |

228.6 |

158.8 |

152.4 |

120.7 |

| 3-1/2 |

101.6 |

266.7 |

184.2 |

177.8 |

139.7 |

| 4 |

114.3 |

304.8 |

209.6 |

203.2 |

158.8 |

| 5 |

141.3 |

381.0 |

261.9 |

254.0 |

196.9 |

| 6 |

168.3 |

457.2 |

312.7 |

304.8 |

236.5 |

| 8 |

219.1 |

609.6 |

414.3 |

406.4 |

312.7 |

| 10 |

273.1 |

762.0 |

517.7 |

508.0 |

390.7 |

| 12 |

323.9 |

914.4 |

619.3 |

609.6 |

466.9 |

| 14 |

355.6 |

1066.8 |

711.2 |

711.2 |

533.4 |

| 16 |

406.4 |

1219.2 |

812.8 |

812.8 |

609.6 |

| 18 |

457.2 |

1371.6 |

914.4 |

914.4 |

685.8 |

| 20 |

508.0 |

1524.0 |

1016.0 |

1016.0 |

762.0 |

| 22 |

558.8 |

1676.4 |

1117.6 |

1117.6 |

838.2 |

| 24 |

609.6 |

1828.8 |

1219.2 |

1219.2 |

914.4 |

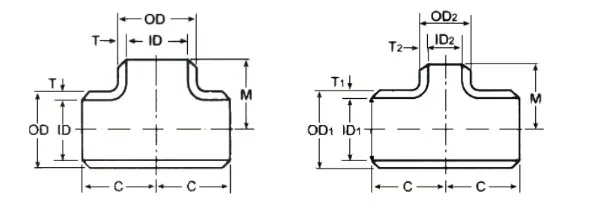

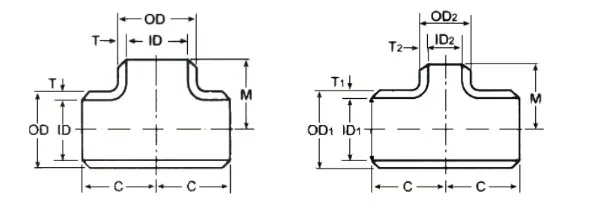

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 1/2 x 1/2 |

21.3 |

21.3 |

25.4 |

25.4 |

| 1/2 x 3/8 |

|

17.1 |

|

25.4 |

| 1/2 x 1/4 |

|

13.7 |

|

25.4 |

| 3/4 x 3/4 |

26.7 |

26.7 |

28.4 |

28.4 |

| 3/4 x 1/2 |

|

21.3 |

|

28.4 |

| 3/4 x 3/8 |

|

17.1 |

|

28.4 |

| 1 x 1 |

33.4 |

33.4 |

38.1 |

38.1 |

| 1 x 3/4 |

|

26.7 |

|

38.1 |

| 1 x 1/2 |

|

21.3 |

|

38.1 |

| 1-1/4 x 1-1/4 |

42.2 |

42.2 |

47.8 |

47.8 |

| 1-1/4 x 1 |

|

33.4 |

|

47.8 |

| 1-1/4 x 3/4 |

|

26.7 |

|

47.8 |

| 1-1/4 x 1/2 |

|

21.3 |

|

47.8 |

| 1-1/2 x 1-1/2 |

48.3 |

48.3 |

57.2 |

57.2 |

| 1-1/2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 1-1/2 x 1 |

|

33.4 |

|

57.2 |

| 1-1/2 x 3/4 |

|

26.7 |

|

57.2 |

| 1-1/2 x 1/2 |

|

21.3 |

|

57.2 |

| 2 x 2 |

60.3 |

60.3 |

63.5 |

63.5 |

| 2 x 1-1/2 |

|

48.3 |

|

60.5 |

| 2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 2 x 1 |

|

33.4 |

|

50.8 |

| 2 x 3/4 |

|

26.7 |

|

44.4 |

| 2 x 1/2* |

|

21.3 |

|

|

| 2-1/2 x 2-1/2 |

73.0 |

73.0 |

76.2 |

76.2 |

| 2-1/2 x 2 |

|

60.3 |

|

69.8 |

| 2-1/2 x 1-1/2 |

|

48.3 |

|

66.5 |

| 2-1/2 x 1-1/4 |

|

42.2 |

|

63.5 |

| 2-1/2 x 1 |

|

33.4 |

|

57.2 |

| 3 x 3 |

88.9 |

88.9 |

85.9 |

85.9 |

| 3 x 2-1/2 |

|

73.0 |

|

82.6 |

| 3 x 2 |

|

60.3 |

|

76.2 |

| 3 x 1-1/2 |

|

48.3 |

|

73.2 |

| 3 x 1-1/4 |

|

42.2 |

|

69.8 |

| 3 x 1* |

|

33.4 |

|

|

| 3-1/2 x 3-1/2 |

101.6 |

101.6 |

95.2 |

95.2 |

| 3-1/2 x 3 |

|

88.9 |

|

91.9 |

| 3-1/2 x 2-1/2 |

|

73.0 |

|

88.9 |

| 3-1/2 x 2 |

|

60.3 |

|

82.6 |

| 3-1/2 x 1-1/2 |

|

48.3 |

|

79.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 4 x 4 |

114.3 |

114.3 |

104.6 |

104.6 |

| 4 x 3-1/2 |

|

101.6 |

|

101.6 |

| 4 x 3 |

|

88.9 |

|

98.6 |

| 4 x 2-1/2 |

|

73.0 |

|

95.2 |

| 4 x 2 |

|

60.3 |

|

88.9 |

| 4 x 1-1/2 |

|

48.3 |

|

85.9 |

| 4 x 1-1/4 |

|

42.2 |

|

|

| 4 x 1* |

|

33.5 |

|

|

| 5 x 5 |

141.3 |

141.3 |

124.0 |

124.0 |

| 5 x 4 |

|

114.3 |

|

117.3 |

| 5 x 3-1/2 |

|

101.6 |

|

114.3 |

| 5 x 3 |

|

88.9 |

|

111.3 |

| 5 x 2-1/2 |

|

73.0 |

|

108.0 |

| 5 x 2 |

|

60.3 |

|

104.6 |

| 5 x 1-1/2* |

|

48.3 |

|

|

| 6 x 6 |

168.3 |

168.3 |

142.7 |

142.7 |

| 6 x 5 |

|

141.3 |

|

136.7 |

| 6 x 4 |

|

114.3 |

|

130.0 |

| 6 x 3-1/2 |

|

101.6 |

|

127.0 |

| 6 x 3 |

|

88.9 |

|

124.0 |

| 6 x 2-1/2 |

|

73.0 |

|

120.6 |

| 6 x 2* |

|

60.3 |

|

|

| 8 x 8 |

19.1 |

219.1 |

177.8 |

177.8 |

| 8 x 6 |

|

168.3 |

|

168.1 |

| 8 x 5 |

|

141.3 |

|

162.1 |

| 8 x 4 |

|

114.3 |

|

155.4 |

| 8 x 3-1/2 |

|

101.6 |

|

152.4 |

| 8 x 3* |

|

88.9 |

|

|

| 10 x 10 |

273.1 |

273.1 |

215.9 |

215.9 |

| 10 x 8 |

|

219.1 |

|

203.2 |

| 10 x 6 |

|

168.3 |

|

193.5 |

| 10 x 5 |

|

141.3 |

|

190.5 |

| 10 x 4 |

|

114.3 |

|

184.2 |

| 12 x 12 |

323.9 |

323.9 |

254.0 |

254.0 |

| 12 x 10 |

|

273.1 |

|

241.3 |

| 12 x 8 |

|

219.1 |

|

228.6 |

| 12 x 6 |

|

168.3 |

|

218.9 |

| 12 x 5 |

|

141.3 |

|

215.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 14 x 14 |

355.6 |

355.6 |

279.4 |

279.4 |

| 14 x 12 |

|

323.9 |

|

269.7 |

| 14 x 10 |

|

273.1 |

|

257.0 |

| 14 x 8 |

|

219.1 |

|

247.6 |

| 14 x 6 |

|

168.3 |

|

238.3 |

| 16 x 16 |

406.4 |

406.4 |

304.8 |

304.8 |

| 16 x 14 |

|

355.6 |

|

304.8 |

| 16 x 12 |

|

323.9 |

|

295.1 |

| 16 x 10 |

|

273.1 |

|

282.4 |

| 16 x 8 |

|

219.1 |

|

373.0 |

| 16 x 6 |

|

168.3 |

|

263.7 |

| 18 x 18 |

457.2 |

457.2 |

342.9 |

342.9 |

| 18 x 16 |

|

406.4 |

|

330.2 |

| 18 x 14 |

|

355.6 |

|

330.2 |

| 18 x 12 |

|

323.9 |

|

320.5 |

| 18 x 10 |

|

273.1 |

|

307.8 |

| 18 x 8 |

|

219.1 |

|

298.4 |

| 20 x 20 |

508.0 |

508.0 |

381.0 |

381.0 |

| 20 x 18 |

|

457.2 |

|

369.3 |

| 20 x 16 |

|

406.4 |

|

355.6 |

| 20 x 14 |

|

355.6 |

|

355.6 |

| 20 x 12 |

|

323.9 |

|

345.9 |

| 20 x 10 |

|

273.1 |

|

333.2 |

| 20 x 8 |

|

219.1 |

|

323.8 |

| 22 x 22 |

558.8 |

558.8 |

419.1 |

419.1 |

| 22 x 20 |

|

508.0 |

|

406.4 |

| 22 x 18 |

|

457.2 |

|

393.7 |

| 22 x 16 |

|

406.4 |

|

381.0 |

| 22 x 14 |

|

355.6 |

|

381.0 |

| 22 x 12 |

|

323.9 |

|

371.3 |

| 22 x 10 |

|

273.1 |

|

358.6 |

| 24 x 24 |

609.6 |

609.6 |

431.8 |

431.8 |

| 24 x 22 |

|

558.8 |

|

431.8 |

| 24 x 20 |

|

508.0 |

|

431.8 |

| 24 x 18 |

|

457.2 |

|

419.1 |

| 24 x 16 |

|

406.4 |

|

406.4 |

| 24 x 14 |

|

355.6 |

|

406.4 |

| 24 x 12 |

|

323.9 |

|

396.7 |

| 24 x 10 |

|

273.1 |

|

384.0 |

| 26 x 26 |

660.4 |

660.4 |

495.3 |

495.3 |

| 26 x 24 |

|

609.6 |

|

482.6 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 26 x 22 |

|

558.8 |

|

469.9 |

| 26 x 20 |

|

508.0 |

|

457.2 |

| 26 x 18 |

|

457.2 |

|

444.5 |

| 26 x 16 |

|

406.4 |

|

431.8 |

| 26 x 14 |

|

355.6 |

|

431.8 |

| 26 x 12 |

|

323.1 |

|

422.1 |

| 28 x 28 |

711.2 |

711.2 |

520.7 |

520.7 |

| 28 x 26 |

|

660.4 |

|

520.7 |

| 28 x 24 |

|

609.6 |

|

508.0 |

| 28 x 22 |

|

558.8 |

|

495.3 |

| 28 x 20 |

|

508.0 |

|

482.6 |

| 28 x 18 |

|

457.2 |

|

469.9 |

| 28 x 16 |

|

406.4 |

|

457.2 |

| 28 x 14 |

|

355.6 |

|

457.2 |

| 28 x 12 |

|

323.1 |

|

447.5 |

| 30 x 30 |

762.0 |

762.0 |

558.8 |

558.8 |

| 30 x 28 |

|

711.2 |

|

546.1 |

| 30 x 26 |

|

660.4 |

|

546.1 |

| 30 x 24 |

|

609.6 |

|

533.4 |

| 30 x 22 |

|

558.8 |

|

520.7 |

| 30 x 20 |

|

508.0 |

|

508.0 |

| 30 x 18 |

|

457.2 |

|

495.3 |

| 30 x 16 |

|

406.4 |

|

482.6 |

| 30 x 14 |

|

355.6 |

|

482.6 |

| 30 x 12 |

|

323.9 |

|

472.6 |

| 30 x 10 |

|

273.1 |

|

460.2 |

| 32 x 32 |

812.8 |

812.8 |

596.9 |

596.9 |

| 32 x 30 |

|

762.0 |

|

584.2 |

| 32 x 28 |

|

711.2 |

|

571.5 |

| 32 x 26 |

|

660.4 |

|

571.5 |

| 32 x 24 |

|

609.6 |

|

558.8 |

| 32 x 22 |

|

558.8 |

|

546.1 |

| 32 x 20 |

|

508.0 |

|

533.4 |

| 32 x 18 |

|

457.2 |

|

520.7 |

| 32 x 16 |

|

406.4 |

|

508.0 |

| 32 x 14 |

|

355.6 |

|

508.0 |

| 34 x 34 |

863.6 |

863.6 |

635.0 |

635.0 |

| 34 x 32 |

|

812.8 |

|

622.3 |

| 34 x 30 |

|

762.0 |

|

609.6 |

| 34 x 28 |

|

711.2 |

|

596.9 |

| 34 x 26 |

|

660.4 |

|

596.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 34 x 24 |

|

609.6 |

|

584.2 |

| 34 x 22 |

|

558.8 |

|

571.5 |

| 34 x 20 |

|

508.0 |

|

558.8 |

| 34 x 18 |

|

457.2 |

|

546.1 |

| 34 x 16 |

|

406.4 |

|

533.4 |

| 36 x 36 |

914.4 |

914.4 |

673.1 |

673.1 |

| 36 x 34 |

|

863.6 |

|

660.4 |

| 36 x 32 |

|

812.8 |

|

647.7 |

| 36 x 30 |

|

762.0 |

|

635.0 |

| 36 x 28 |

|

711.2 |

|

622.3 |

| 36 x 26 |

|

660.4 |

|

622.3 |

| 36 x 24 |

|

609.6 |

|

609.6 |

| 36 x 22 |

|

558.8 |

|

596.9 |

| 36 x 20 |

|

508.0 |

|

584.2 |

| 36 x 18 |

|

457.2 |

|

571.5 |

| 36 x 16 |

|

406.4 |

|

558.8 |

| 38 x 38 |

965.2 |

965.2 |

711.2 |

711.2 |

| 38 x 36 |

|

914.4 |

|

711.2 |

| 38 x 34 |

|

863.6 |

|

698.5 |

| 38 x 32 |

|

812.8 |

|

685.8 |

| 38 x 30 |

|

762.0 |

|

673.1 |

| 38 x 28 |

|

711.2 |

|

647.7 |

| 38 x 26 |

|

660.4 |

|

647.7 |

| 38 x 24 |

|

609.6 |

|

635.0 |

| 38 x 22 |

|

558.8 |

|

622.3 |

| 38 x 20 |

|

508.0 |

|

609.6 |

| 38 x 18 |

|

457.2 |

|

596.9 |

| 40 x 40 |

1016.0 |

1016.0 |

749.3 |

749.3 |

| 40 x 38 |

|

965.2 |

|

749.3 |

| 40 x 36 |

|

914.4 |

|

736.6 |

| 40 x 34 |

|

863.6 |

|

723.9 |

| 40 x 32 |

|

812.8 |

|

711.2 |

| 40 x 30 |

|

762.0 |

|

698.5 |

| 40 x 28 |

|

711.2 |

|

673.1 |

| 40 x 26 |

|

660.4 |

|

673.1 |

| 40 x 24 |

|

609.6 |

|

660.4 |

| 40 x 22 |

|

558.8 |

|

647.7 |

| 40 x 20 |

|

508.0 |

|

635.0 |

| 40 x 18 |

|

457.2 |

|

622.3 |

| 42 x 42 |

1066.8 |

1066.8 |

762.0 |

711.2 |

| 42 x 40 |

|

1016.0 |

|

711.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 42 x 38 |

|

965.2 |

|

711.2 |

| 42 x 36 |

|

914.4 |

|

711.2 |

| 42 x 34 |

|

863.6 |

|

711.2 |

| 42 x 32 |

|

812.8 |

|

711.2 |

| 42 x 30 |

|

762.0 |

|

711.2 |

| 42 x 28 |

1066.8 |

711.2 |

762.0 |

698.5 |

| 42 x 26 |

|

660.4 |

|

698.5 |

| 42 x 24 |

|

609.6 |

|

660.4 |

| 42 x 22 |

|

558.8 |

|

660.4 |

| 42 x 20 |

|

508.0 |

|

660.4 |

| 42 x 18 |

|

457.2 |

|

647.7 |

| 42 x 16 |

|

406.4 |

|

635.0 |

| 44 x 44 |

1117.6 |

1117.6 |

812.8 |

762.0 |

| 44 x 42 |

|

1066.8 |

|

762.0 |

| 44 x 40 |

|

1016.0 |

|

749.3 |

| 44 x 38 |

|

965.2 |

|

736.6 |

| 44 x 36 |

|

914.4 |

|

723.9 |

| 44 x 34 |

|

863.6 |

|

723.9 |

| 44 x 32 |

|

812.8 |

|

711.2 |

| 44 x 30 |

|

762.0 |

|

711.2 |

| 44 x 28 |

|

711.2 |

|

698.5 |

| 44 x 26 |

|

660.4 |

|

698.5 |

| 44 x 24 |

|

609.6 |

|

698.5 |

| 44 x 22 |

|

558.8 |

|

685.8 |

| 44 x 20 |

|

508.0 |

|

685.8 |

| 46 x 46 |

1168.4 |

1168.4 |

850.9 |

800.1 |

| 46 x 44 |

|

1117.6 |

|

800.1 |

| 46 x 42 |

|

1066.8 |

|

787.4 |

| 46 x 40 |

|

1016.0 |

|

774.7 |

| 46 x 38 |

|

965.2 |

|

762.0 |

| 46 x 36 |

|

914.4 |

|

762.0 |

| 46 x 34 |

|

863.6 |

|

749.3 |

| 46 x 32 |

|

812.8 |

|

749.3 |

| 46 x 30 |

|

762.0 |

|

736.6 |

| 46 x 28 |

|

711.2 |

|

736.6 |

| 46 x 26 |

|

660.4 |

|

736.6 |

| 46 x 24 |

|

609.6 |

|

723.9 |

| 46 x 20* |

|

508.0 |

|

723.9 |

| 48 x 48 |

1219.2 |

1219.2 |

889.0 |

838.2 |

| 48 x 46 |

|

1168.4 |

|

838.2 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

1219.2 |

812.8 |

889.0 |

787.4 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

|

812.8 |

|

787.4 |

| 48 x 30 |

|

762.0 |

|

762.0 |

| 48 x 28 |

|

711.2 |

|

762.0 |

| 48 x 26 |

|

660.4 |

|

762.0 |

| 48 x 24 |

|

609.6 |

|

736.6 |

| 48 x 22 |

|

558.8 |

|

736.6 |

| 52 x 52* |

1320.8 |

1320.8 |

965.2 |

914.4 |

| 52 x 48* |

|

1219.2 |

|

863.6 |

| 52 x 44* |

|

1117.6 |

|

812.8 |

| 52 x 40* |

|

1016.0 |

|

762.0 |

| 54 x 54* |

1371.6 |

1371.6 |

1003.3 |

952.5 |

| 54 x 52* |

|

1320.8 |

|

914.4 |

| 54 x 48* |

|

1219.2 |

|

863.6 |

| 54 x 44* |

|

1117.6 |

|

863.6 |

| 54 x 40* |

|

1016.0 |

|

812.8 |

| 54 x 28* |

|

711.2 |

|

787.4 |

| 54 x 20* |

|

508.0 |

|

787.4 |

| 56 x 56* |

1422.4 |

1422.4 |

1041.4 |

965.2 |

| 56 x 52* |

|

1320.8 |

|

914.4 |

| 56 x 48* |

|

1219.2 |

|

863.6 |

| 56 x 44* |

|

1117.6 |

|

812.8 |

| 56 x 40* |

|

1016.0 |

|

812.8 |

| 56 x 28* |

|

711.2 |

|

812.8 |

| 56 x 20* |

|

508.0 |

|

812.8 |

| 60 x 60* |

1524.0 |

1524.0 |

1117.6 |

1016.0 |

| 60 x 56* |

|

1422.4 |

|

965.2 |

| 60 x 52* |

|

1320.8 |

|

914.4 |

| 60 x 48* |

|

1219.2 |

|

863.6 |

| 60 x 40* |

|

1016.0 |

|

863.6 |

| 60 x 28* |

|

711.2 |

|

863.6 |

| 60 x 20* |

|

508.0 |

|

863.6 |

| 64 x 64* |

1626.0 |

1626.0 |

1194.0 |

1092.0 |

| 64 x 60* |

|

1524.0 |

|

1067.0 |

| 64 x 56* |

|

1422.0 |

|

1016.0 |

| 64 x 52* |

|

1321.0 |

|

965.0 |

| 64 x 48* |

|

1219.0 |

|

914 |

| 66 x 66* |

1676.4 |

1676.4 |

1219.2 |

1066.8 |

| 68 x 68* |

1727.0 |

1727.0 |

1270.0 |

1168.0 |

| 68 x 64* |

|

1626.0 |

|

1143.0 |

| 68 x 60* |

|

1524.0 |

|

1118.0 |

| 68 x 56* |

|

1422.0 |

|

1067.0 |

| 68 x 52* |

|

1321.0 |

|

1016.0 |

| 68 x 48* |

|

1219.0 |

|

965.0 |

| 72 x 72* |

1829.0 |

1829.0 |

1320.0 |

1245.0 |

| 72 x 68* |

|

1727.0 |

|

1219.0 |

| 72 x 64* |

|

1626.0 |

|

1194.0 |

| 72 x 60* |

|

1524.0 |

|

1168.0 |

| 72 x 56* |

1829.0 |

1422.0 |

1320.0 |

1118.0 |

| 72 x 52* |

|

1321.0 |

|

1067.0 |

| 72 x 48* |

|

1219.0 |

|

1016.0 |

| 76 x 76* |

1930.0 |

1930.0 |

1422.0 |

1320.0 |

| 76 x 72* |

|

1829.0 |

|

1295.0 |

| 76 x 68* |

|

1727.0 |

|

1270.0 |

| 76 x 64* |

|

1626.0 |

|

1245.0 |

| 76 x 60* |

|

1524.0 |

|

1219.0 |

| 76 x 56* |

|

1422.0 |

|

1168.0 |

| 76 x 52* |

|

1321.0 |

|

1118.0 |

| 76 x 48* |

|

1219.0 |

|

1067.0 |

| 80 x 80* |

2032.0 |

2032.0 |

1499.0 |

1397.0 |

| 80 x 76* |

|

1930.0 |

|

1372.0 |

| 80 x 72* |

|

1829.0 |

|

1346.0 |

| 80 x 68* |

|

1727.0 |

|

1321.0 |

| 80 x 64* |

|

1626.0 |

|

1295.0 |

| 80 x 60* |

|

1524.0 |

|

1270.0 |

| 80 x 56* |

|

1422.0 |

|

1219.0 |

| 80 x 52* |

|

1321.0 |

|

1168.0 |

| 80 x 48* |

|

1219.0 |

|

1118.0 |

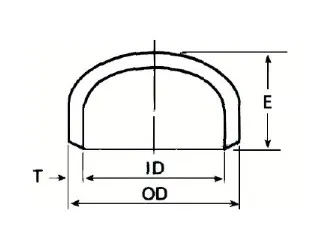

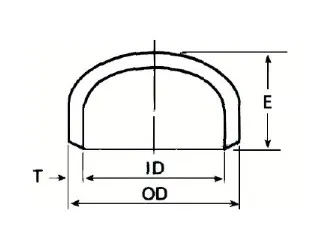

ANSI B16.9 / MSS SP-75 Cap Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel D |

Center to End E |

| 1/2 |

21.3 |

25.4 |

| 3/4 |

26.7 |

25.4 |

| 1 |

33.4 |

38.1 |

| 1-1/4 |

42.2 |

38.1 |

| 1-1/2 |

48.3 |

38.1 |

| 2 |

60.3 |

38.1 |

| 2-1/2 |

73.0 |

38.1 |

| 3 |

88.9 |

50.8 |

| 3-1/2 |

101.6 |

63.5 |

| 4 |

114.3 |

63.5 |

| 5 |

141.3 |

76.2 |

| 6 |

168.3 |

88.9 |

| 8 |

219.1 |

101.6 |

| 10 |

273.1 |

127.0 |

| 12 |

323.9 |

152.4 |

| 14 |

355.6 |

165.1 |

| 16 |

406.4 |

177.8 |

| 18 |

457.2 |

203.2 |

| 20 |

508.0 |

228.6 |

| 22 |

558.8 |

254.0 |

| 24 |

609.6 |

266.7 |

| 26 |

660.4 |

266.7 |

| 28 |

711.2 |

266.7 |

| 30 |

762.0 |

266.7 |

| 32 |

812.8 |

266.7 |

| 34 |

863.6 |

266.7 |

| 36 |

914.4 |

266.7 |

| 38 |

965.2 |

304.8 |

| 40 |

1016.0 |

304.8 |

| 42 |

1066.8 |

304.8 |

| 44 |

1117.6 |

342.9 |

| 46 |

1168.4 |

342.9 |

| 48 |

1219.2 |

342.9 |

ANSI B36.19M Wall Thickness Schedule Dimension Chart (mm, kg)

| Nominal Pipe Size |

Outside Diameter |

Nominal Wall Thickness |

| A |

B |

JIS |

ANSI |

Sch 5S |

Sch 10S |

Sch 20S |

GS |

Sch 10 |

LG (7.9) |

Sch 20 |

Sch 30 |

STD |

Sch 40 |

Sch 60 |

XS |

Sch 80 |

Sch 100 |

Sch 120 |

Sch 140 |

Sch 160 |

XXS |

| 8 |

1/4 |

13.8 |

13.7 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.2) |

2.2 |

2.4 |

(3.0) |

3.0 |

- |

- |

- |

- |

- |

| 10 |

3/8 |

17.3 |

17.1 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.3) |

2.3 |

2.8 |

(3.2) |

3.2 |

- |

- |

- |

- |

- |

| 15 |

1/2 |

21.7 |

21.3 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.8) |

2.8 |

3.2 |

(3.7) |

3.7 |

- |

- |

- |

4.7 |

7.5 |

| 20 |

3/4 |

27.2 |

26.7 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.9) |

2.9 |

3.4 |

(3.9) |

3.9 |

- |

- |

- |

5.5 |

7.8 |

| 25 |

1 |

34.0 |

33.4 |

1.65 |

2.8 |

3.0 |

3.2 |

- |

- |

- |

- |

(3.4) |

3.4 |

3.9 |

(4.5) |

4.5 |

- |

- |

- |

6.4 |

9.1 |

| 32 |

1-1/4 |

42.7 |

42.2 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.6) |

3.6 |

4.5 |

(4.9) |

4.9 |

- |

- |

- |

6.4 |

9.7 |

| 40 |

1-1/2 |

48.6 |

48.3 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.7) |

3.7 |

4.5 |

(5.1) |

5.1 |

- |

- |

- |

7.1 |

10.2 |

| 50 |

2 |

60.5 |

60.3 |

1.65 |

2.8 |

3.5 |

3.8 |

- |

- |

- |

- |

(3.9) |

3.9 |

4.9 |

(5.5) |

5.5 |

- |

- |

- |

8.7 |

11.1 |

| 65 |

2-1/2 |

76.3 |

73.0 |

2.1 |

3.0 |

3.5 |

4.2 |

- |

- |

- |

- |

(5.2) |

5.2 |

6.0 |

(7.0) |

7.0 |

- |

- |

- |

9.5 |

14.0 |

| 80 |

3 |

89.1 |

88.9 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.5) |

5.5 |

6.6 |

(7.6) |

7.6 |

- |

- |

- |

11.1 |

15.2 |

| 90 |

3-1/2 |

101.6 |

101.6 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.7) |

5.7 |

7.0 |

(8.1) |

8.1 |

- |

- |

- |

12.7 |

- |

| 100 |

4 |

114.3 |

114.3 |

2.1 |

3.0 |

4.0 |

4.5 |

- |

- |

- |

- |

(6.0) |

6.0 |

7.1 |

(8.6) |

8.6 |

- |

11.1 |

- |

13.5 |

17.1 |

| 125 |

5 |

139.8 |

141.3 |

2.8 |

3.4 |

5.0 |

4.5 |

- |

- |

- |

- |

(6.6) |

6.6 |

8.1 |

(9.5) |

9.5 |

- |

12.7 |

- |

15.9 |

19.0 |

| 150 |

6 |

165.2 |

168.3 |

2.8 |

3.4 |

5.0 |

5.0 |

- |

5.0** |

- |

- |

(7.1) |

7.1 |

9.3 |

(11.0) |

11.0 |

- |

14.3 |

- |

18.2 |

21.9 |

| 175 |

7 |

190.7 |

- |

- |

- |

- |

5.3 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 200 |

8 |

216.3 |

219.1 |

2.8 |

3.8 |

6.5 |

5.8 |

- |

5.8** |

6.4 |

7.0 |

(8.2) |

8.2 |

10.3 |

(12.7) |

12.7 |

15.1 |

18.2 |

20.6 |

23.0 |

22.2 |

| 225 |

9 |

241.8 |

- |

- |

- |

- |

6.2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 250 |

10 |

267.4 |

273.1 |

3.4 |

4.2 |

6.5 |

6.6 |

- |

6.6** |

6.4 |

7.8 |

(9.3) |

9.3 |

12.7 |

12.7 |

15.1 |

18.3 |

21.4 |

25.4 |

28.6 |

25.4 |

| 300 |

12 |

318.5 |

323.9 |

4.0 |

4.6 |

6.5 |

6.9 |

- |

6.9** |

6.4 |

8.4 |

9.5 |

10.3 |

14.3 |

12.7 |

17.4 |

21.4 |

25.4 |

28.6 |

33.3 |

25.4 |

| 350 |

14 |

355.6 |

355.6 |

4.0 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

11.1 |

15.1 |

12.7 |

19.0 |

23.8 |

27.8 |

31.8 |

35.7 |

- |

| 400 |

16 |

406.4 |

406.4 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

12.7 |

16.7 |

12.7 |

21.4 |

26.2 |

30.9 |

36.5 |

40.5 |

- |

| 450 |

18 |

457.2 |

457.2 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

11.1 |

9.5 |

14.3 |

19.0 |

12.7 |

23.8 |

29.4 |

34.9 |

39.7 |

45.2 |

- |

| 500 |

20 |

508.0 |

508.0 |

4.8 |

5.5 |

7.9 |

7.9 |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

15.1 |

20.6 |

12.7 |

26.2 |

32.5 |

38.1 |

44.4 |

50.0 |

- |

| 550 |

22 |

558.8 |

558.8 |

4.8 |

5.5 |

- |

- |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

- |

22.2 |

12.7 |

28.6 |

34.9 |

41.3 |

47.6 |

54.0 |

- |

| 600 |

24 |

609.6 |

609.6 |

5.5 |

6.4 |

- |

- |

6.4 |

7.9 |

9.5 |

14.3 |

9.5 |

17.5 |

24.6 |

12.7 |

31.0 |

38.9 |

46.0 |

52.4 |

59.5 |

- |

| 650 |

26 |

660.4 |

660.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 700 |

28 |

711.2 |

711.2 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 750 |

30 |

762.0 |

762.0 |

6.4 |

7.9 |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 800 |

32 |

812.8 |

812.8 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 850 |

34 |

863.6 |

863.6 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 900 |

36 |

914.4 |

914.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

19.1 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 950 |

38 |

965.2 |

965.2 |

- |

- |

- |

- |

- |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1000 |

40 |

1016.0 |

1016.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1050 |

42 |

1066.8 |

1066.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1100 |

44 |

1117.6 |

1117.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1150 |

46 |

1168.4 |

1168.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1200 |

48 |

1219.2 |

1219.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1250 |

50 |

1270.0 |

1270.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1300 |

52 |

1320.8 |

1320.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1350 |

54 |

1371.6 |

1371.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1400 |

56 |

1422.4 |

1422.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1450 |

58 |

1473.2 |

1473.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1500 |

60 |

1524.0 |

1524.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1600 |

64 |

1626.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1700 |

68 |

1727.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1800 |

72 |

1829.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1900 |

76 |

1932.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2000 |

80 |

2032.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions in accordance with JIS G3448, JIS G3455, JIS G3454, JIS G3459, ANSI B36.10M