ANSI B16.9 Monel Buttweld Fittings Weight, Dimensions Chart in mm, kg, PDF online

Monel buttweld fittings are a type of pipe fittings made from Monel, a high-performance alloy primarily

composed of nickel and copper, with small amounts of iron, manganese, carbon, and other elements. Monel

is known for its exceptional corrosion resistance, making it suitable for various applications,

especially in environments where resistance to harsh chemicals, seawater, and other corrosive substances

is required. Monel buttweld fittings are typically made from Monel alloy grades such as Monel 400 (UNS

N04400) and Monel K-500 (UNS N05500). Monel 400 contains approximately 67% nickel, 28% copper, and small

amounts of iron, manganese, carbon, and other elements. Monel K-500 has additional elements like

aluminum and titanium, providing enhanced strength and hardness. The term "buttweld" refers to the

method of joining pipes and fittings by welding the ends together. Monel buttweld fittings are

manufactured using a welding process that creates a smooth, strong, and leak-free connection between

pipes or other components. Monel buttweld fittings are manufactured to a variety of standards, including

ANSI B16.9, ANSI B16.28, and ANSI B36.19M. Monel buttweld fittings weight and dimensions chart PDF can

make you understand more about these specifications. Monel buttweld fittings are available in a variety

of sizes and schedules. The size of a fitting refers to its nominal diameter, which is the inner

diameter of the pipe that it is designed to fit. The schedule of a fitting refers to its wall thickness.

Features:

- Excellent corrosion resistance

- Good weldability

- Long service life

- High strength

- Temperature resistance

- Low maintenance costs

- Reduced risk of downtime

Applications:

- Oil and gas industry: pipelines, heat exchangers, pressure vessels, offshore structures

- Chemical processing industry: reactors, distillation columns, piping systems

- Marine industry: seawater piping systems, desalination plants, ship hulls

- Power generation industry: boilers, condensers, piping systems

- Other industries: food processing, pharmaceutical, pulp and paper

Specifications of Monel Buttweld Fittings

Monel buttweld fittings are manufactured in accordance with a variety of standards, including ANSI B16.9,

ANSI B16.28, MSS SP-75 and ANSI B36.19M to ensure quality and compatibility with piping systems. All the

specifications of monel buttweld fittings are mentioned in the weight and dimensions chart PDF given in

mm and kg dimensions in complete details below.

Types of Monel Buttweld fitting:

The types of Monel Buttweld fitting are:

- Elbows

- Tees

- Reducers

- Cap

- Stub End

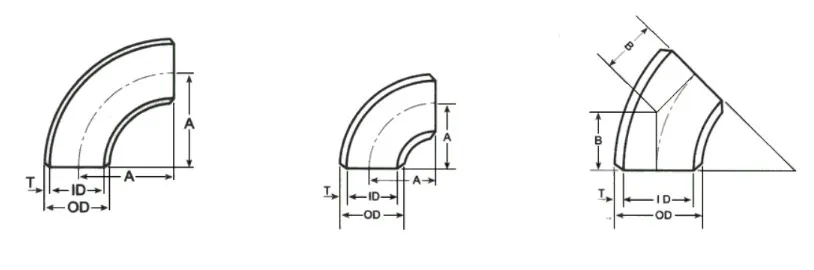

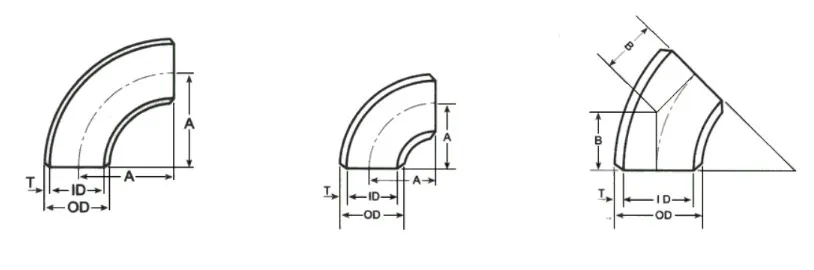

ANSI B16.9/B16.28 90°/45° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel(OD) |

Center to End |

| Long Radius Elbow |

Short Radius Elbow |

| 90 degree. A |

45 degree B |

90 degree A |

| 1/2 |

21.3 |

38.1 |

15.7 |

- |

| 3/4 |

26.7 |

38.1 |

19.1 |

- |

| 1 |

33.4 |

38.1 |

22.4 |

25.4 |

| 1-1/4 |

42.2 |

47.8 |

25.4 |

31.8 |

| 1-1/2 |

48.3 |

57.2 |

28.4 |

38.1 |

| 2 |

60.3 |

76.2 |

35.1 |

50.8 |

| 2-1/2 |

73.0 |

95.2 |

44.4 |

63.5 |

| 3 |

88.9 |

114.3 |

50.8 |

76.2 |

| 3-1/2 |

101.6 |

133.4 |

57.2 |

88.9 |

| 4 |

114.3 |

152.4 |

63.5 |

101.6 |

| 5 |

141.3 |

190.5 |

79.2 |

127.0 |

| 6 |

168.3 |

228.6 |

95.2 |

152.4 |

| 8 |

219.1 |

304.8 |

127.0 |

203.2 |

| 10 |

273.1 |

381.0 |

158.8 |

254.0 |

| 12 |

323.9 |

457.2 |

190.5 |

304.8 |

| 14 |

355.6 |

533.4 |

222.2 |

355.6 |

| 16 |

406.4 |

609.6 |

254.0 |

406.4 |

| 18 |

457.2 |

685.8 |

285.8 |

457.2 |

| 20 |

508.0 |

762.0 |

317.5 |

508.0 |

| 22 |

558.8 |

838.2 |

342.9 |

558.8 |

| 24 |

609.6 |

914.4 |

381.0 |

609.6 |

| 26 |

660.4 |

990.6 |

406.4 |

660.4 |

| 28 |

711.2 |

1066.8 |

438.2 |

711.2 |

| 30 |

762.0 |

1143.0 |

469.9 |

762.0 |

| 32 |

812.8 |

1219.2 |

501.6 |

812.8 |

| 34 |

863.6 |

1295.4 |

533.4 |

863.6 |

| 36 |

914.4 |

1371.6 |

565.2 |

914.4 |

| 38 |

965.2 |

1447.8 |

599.9 |

- |

| 40 |

1016.0 |

1524.0 |

632.0 |

1016.0 |

| 42 |

1066.8 |

1600.2 |

660.4 |

1066.8 |

| 44 |

1117.6 |

1676.4 |

695.5 |

1117.6 |

| 46 |

1168.4 |

1752.6 |

726.9 |

- |

| 48 |

1219.2 |

1828.8 |

759.0 |

1219.2 |

| 52* |

1320.8 |

- |

- |

1320.8 |

| 54* |

1371.6 |

2057.4 |

852.2 |

1371.6 |

| 56* |

1422.4 |

2133.6 |

883.8 |

1422.4 |

| 60* |

1524.0 |

2286.0 |

946.9 |

1524.0 |

| 66* |

1676.4 |

2514.6 |

1041.6 |

- |

| 68* |

1727.0 |

2591 |

1073 |

1727 |

| 72* |

1829.0 |

2743 |

1137 |

1829 |

| 76* |

1930.0 |

2896 |

1199 |

1930 |

| 80* |

2032.0 |

3048 |

1263 |

2032 |

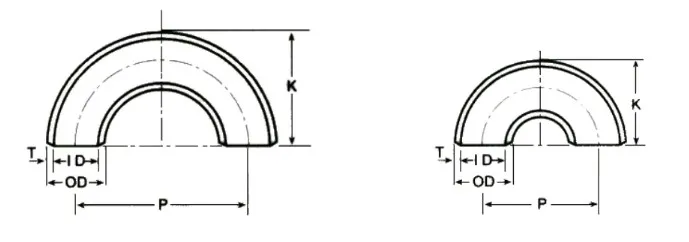

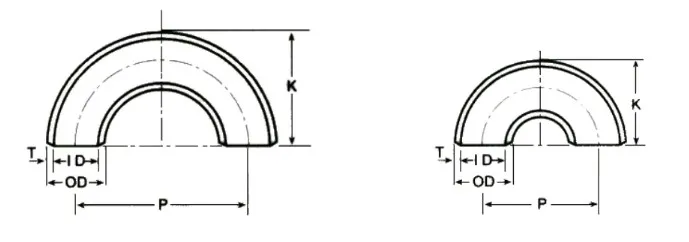

ANSI B16.9/B16.28 180° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel OD |

Long Radius Elbow |

Short Radius Elbow |

| Short Radius Elbow |

Center to Center. P |

Back to Face K |

| 1/2 |

21.3 |

76.2 |

47.8 |

- |

- |

| 3/4 |

26.7 |

76.2 |

50.8 |

- |

- |

| 1 |

33.4 |

76.2 |

55.6 |

50.8 |

41.1 |

| 1-1/4 |

42.2 |

95.2 |

69.8 |

63.5 |

52.3 |

| 1-1/2 |

48.3 |

114.3 |

82.6 |

76.2 |

62.0 |

| 2 |

60.3 |

152.4 |

106.4 |

101.6 |

81.0 |

| 2-1/2 |

73.0 |

109.5 |

131.8 |

127.0 |

100.1 |

| 3 |

88.9 |

228.6 |

158.8 |

152.4 |

120.7 |

| 3-1/2 |

101.6 |

266.7 |

184.2 |

177.8 |

139.7 |

| 4 |

114.3 |

304.8 |

209.6 |

203.2 |

158.8 |

| 5 |

141.3 |

381.0 |

261.9 |

254.0 |

196.9 |

| 6 |

168.3 |

457.2 |

312.7 |

304.8 |

236.5 |

| 8 |

219.1 |

609.6 |

414.3 |

406.4 |

312.7 |

| 10 |

273.1 |

762.0 |

517.7 |

508.0 |

390.7 |

| 12 |

323.9 |

914.4 |

619.3 |

609.6 |

466.9 |

| 14 |

355.6 |

1066.8 |

711.2 |

711.2 |

533.4 |

| 16 |

406.4 |

1219.2 |

812.8 |

812.8 |

609.6 |

| 18 |

457.2 |

1371.6 |

914.4 |

914.4 |

685.8 |

| 20 |

508.0 |

1524.0 |

1016.0 |

1016.0 |

762.0 |

| 22 |

558.8 |

1676.4 |

1117.6 |

1117.6 |

838.2 |

| 24 |

609.6 |

1828.8 |

1219.2 |

1219.2 |

914.4 |

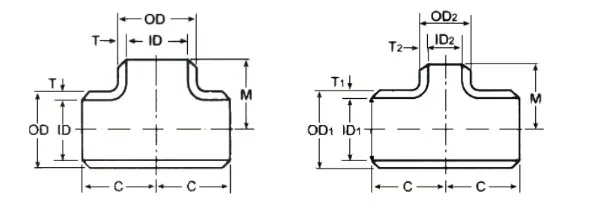

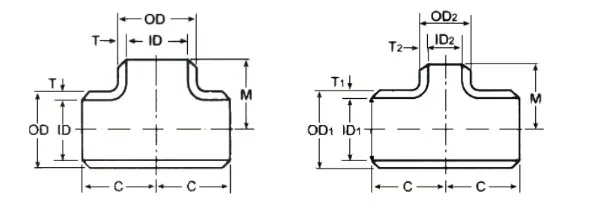

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 1/2 x 1/2 |

21.3 |

21.3 |

25.4 |

25.4 |

| 1/2 x 3/8 |

|

17.1 |

|

25.4 |

| 1/2 x 1/4 |

|

13.7 |

|

25.4 |

| 3/4 x 3/4 |

26.7 |

26.7 |

28.4 |

28.4 |

| 3/4 x 1/2 |

|

21.3 |

|

28.4 |

| 3/4 x 3/8 |

|

17.1 |

|

28.4 |

| 1 x 1 |

33.4 |

33.4 |

38.1 |

38.1 |

| 1 x 3/4 |

|

26.7 |

|

38.1 |

| 1 x 1/2 |

|

21.3 |

|

38.1 |

| 1-1/4 x 1-1/4 |

42.2 |

42.2 |

47.8 |

47.8 |

| 1-1/4 x 1 |

|

33.4 |

|

47.8 |

| 1-1/4 x 3/4 |

|

26.7 |

|

47.8 |

| 1-1/4 x 1/2 |

|

21.3 |

|

47.8 |

| 1-1/2 x 1-1/2 |

48.3 |

48.3 |

57.2 |

57.2 |

| 1-1/2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 1-1/2 x 1 |

|

33.4 |

|

57.2 |

| 1-1/2 x 3/4 |

|

26.7 |

|

57.2 |

| 1-1/2 x 1/2 |

|

21.3 |

|

57.2 |

| 2 x 2 |

60.3 |

60.3 |

63.5 |

63.5 |

| 2 x 1-1/2 |

|

48.3 |

|

60.5 |

| 2 x 1-1/4 |

|

42.2 |

|

57.2 |

| 2 x 1 |

|

33.4 |

|

50.8 |

| 2 x 3/4 |

|

26.7 |

|

44.4 |

| 2 x 1/2* |

|

21.3 |

|

|

| 2-1/2 x 2-1/2 |

73.0 |

73.0 |

76.2 |

76.2 |

| 2-1/2 x 2 |

|

60.3 |

|

69.8 |

| 2-1/2 x 1-1/2 |

|

48.3 |

|

66.5 |

| 2-1/2 x 1-1/4 |

|

42.2 |

|

63.5 |

| 2-1/2 x 1 |

|

33.4 |

|

57.2 |

| 3 x 3 |

88.9 |

88.9 |

85.9 |

85.9 |

| 3 x 2-1/2 |

|

73.0 |

|

82.6 |

| 3 x 2 |

|

60.3 |

|

76.2 |

| 3 x 1-1/2 |

|

48.3 |

|

73.2 |

| 3 x 1-1/4 |

|

42.2 |

|

69.8 |

| 3 x 1* |

|

33.4 |

|

|

| 3-1/2 x 3-1/2 |

101.6 |

101.6 |

95.2 |

95.2 |

| 3-1/2 x 3 |

|

88.9 |

|

91.9 |

| 3-1/2 x 2-1/2 |

|

73.0 |

|

88.9 |

| 3-1/2 x 2 |

|

60.3 |

|

82.6 |

| 3-1/2 x 1-1/2 |

|

48.3 |

|

79.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 4 x 4 |

114.3 |

114.3 |

104.6 |

104.6 |

| 4 x 3-1/2 |

|

101.6 |

|

101.6 |

| 4 x 3 |

|

88.9 |

|

98.6 |

| 4 x 2-1/2 |

|

73.0 |

|

95.2 |

| 4 x 2 |

|

60.3 |

|

88.9 |

| 4 x 1-1/2 |

|

48.3 |

|

85.9 |

| 4 x 1-1/4 |

|

42.2 |

|

|

| 4 x 1* |

|

33.5 |

|

|

| 5 x 5 |

141.3 |

141.3 |

124.0 |

124.0 |

| 5 x 4 |

|

114.3 |

|

117.3 |

| 5 x 3-1/2 |

|

101.6 |

|

114.3 |

| 5 x 3 |

|

88.9 |

|

111.3 |

| 5 x 2-1/2 |

|

73.0 |

|

108.0 |

| 5 x 2 |

|

60.3 |

|

104.6 |

| 5 x 1-1/2* |

|

48.3 |

|

|

| 6 x 6 |

168.3 |

168.3 |

142.7 |

142.7 |

| 6 x 5 |

|

141.3 |

|

136.7 |

| 6 x 4 |

|

114.3 |

|

130.0 |

| 6 x 3-1/2 |

|

101.6 |

|

127.0 |

| 6 x 3 |

|

88.9 |

|

124.0 |

| 6 x 2-1/2 |

|

73.0 |

|

120.6 |

| 6 x 2* |

|

60.3 |

|

|

| 8 x 8 |

19.1 |

219.1 |

177.8 |

177.8 |

| 8 x 6 |

|

168.3 |

|

168.1 |

| 8 x 5 |

|

141.3 |

|

162.1 |

| 8 x 4 |

|

114.3 |

|

155.4 |

| 8 x 3-1/2 |

|

101.6 |

|

152.4 |

| 8 x 3* |

|

88.9 |

|

|

| 10 x 10 |

273.1 |

273.1 |

215.9 |

215.9 |

| 10 x 8 |

|

219.1 |

|

203.2 |

| 10 x 6 |

|

168.3 |

|

193.5 |

| 10 x 5 |

|

141.3 |

|

190.5 |

| 10 x 4 |

|

114.3 |

|

184.2 |

| 12 x 12 |

323.9 |

323.9 |

254.0 |

254.0 |

| 12 x 10 |

|

273.1 |

|

241.3 |

| 12 x 8 |

|

219.1 |

|

228.6 |

| 12 x 6 |

|

168.3 |

|

218.9 |

| 12 x 5 |

|

141.3 |

|

215.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 14 x 14 |

355.6 |

355.6 |

279.4 |

279.4 |

| 14 x 12 |

|

323.9 |

|

269.7 |

| 14 x 10 |

|

273.1 |

|

257.0 |

| 14 x 8 |

|

219.1 |

|

247.6 |

| 14 x 6 |

|

168.3 |

|

238.3 |

| 16 x 16 |

406.4 |

406.4 |

304.8 |

304.8 |

| 16 x 14 |

|

355.6 |

|

304.8 |

| 16 x 12 |

|

323.9 |

|

295.1 |

| 16 x 10 |

|

273.1 |

|

282.4 |

| 16 x 8 |

|

219.1 |

|

373.0 |

| 16 x 6 |

|

168.3 |

|

263.7 |

| 18 x 18 |

457.2 |

457.2 |

342.9 |

342.9 |

| 18 x 16 |

|

406.4 |

|

330.2 |

| 18 x 14 |

|

355.6 |

|

330.2 |

| 18 x 12 |

|

323.9 |

|

320.5 |

| 18 x 10 |

|

273.1 |

|

307.8 |

| 18 x 8 |

|

219.1 |

|

298.4 |

| 20 x 20 |

508.0 |

508.0 |

381.0 |

381.0 |

| 20 x 18 |

|

457.2 |

|

369.3 |

| 20 x 16 |

|

406.4 |

|

355.6 |

| 20 x 14 |

|

355.6 |

|

355.6 |

| 20 x 12 |

|

323.9 |

|

345.9 |

| 20 x 10 |

|

273.1 |

|

333.2 |

| 20 x 8 |

|

219.1 |

|

323.8 |

| 22 x 22 |

558.8 |

558.8 |

419.1 |

419.1 |

| 22 x 20 |

|

508.0 |

|

406.4 |

| 22 x 18 |

|

457.2 |

|

393.7 |

| 22 x 16 |

|

406.4 |

|

381.0 |

| 22 x 14 |

|

355.6 |

|

381.0 |

| 22 x 12 |

|

323.9 |

|

371.3 |

| 22 x 10 |

|

273.1 |

|

358.6 |

| 24 x 24 |

609.6 |

609.6 |

431.8 |

431.8 |

| 24 x 22 |

|

558.8 |

|

431.8 |

| 24 x 20 |

|

508.0 |

|

431.8 |

| 24 x 18 |

|

457.2 |

|

419.1 |

| 24 x 16 |

|

406.4 |

|

406.4 |

| 24 x 14 |

|

355.6 |

|

406.4 |

| 24 x 12 |

|

323.9 |

|

396.7 |

| 24 x 10 |

|

273.1 |

|

384.0 |

| 26 x 26 |

660.4 |

660.4 |

495.3 |

495.3 |

| 26 x 24 |

|

609.6 |

|

482.6 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 26 x 22 |

|

558.8 |

|

469.9 |

| 26 x 20 |

|

508.0 |

|

457.2 |

| 26 x 18 |

|

457.2 |

|

444.5 |

| 26 x 16 |

|

406.4 |

|

431.8 |

| 26 x 14 |

|

355.6 |

|

431.8 |

| 26 x 12 |

|

323.1 |

|

422.1 |

| 28 x 28 |

711.2 |

711.2 |

520.7 |

520.7 |

| 28 x 26 |

|

660.4 |

|

520.7 |

| 28 x 24 |

|

609.6 |

|

508.0 |

| 28 x 22 |

|

558.8 |

|

495.3 |

| 28 x 20 |

|

508.0 |

|

482.6 |

| 28 x 18 |

|

457.2 |

|

469.9 |

| 28 x 16 |

|

406.4 |

|

457.2 |

| 28 x 14 |

|

355.6 |

|

457.2 |

| 28 x 12 |

|

323.1 |

|

447.5 |

| 30 x 30 |

762.0 |

762.0 |

558.8 |

558.8 |

| 30 x 28 |

|

711.2 |

|

546.1 |

| 30 x 26 |

|

660.4 |

|

546.1 |

| 30 x 24 |

|

609.6 |

|

533.4 |

| 30 x 22 |

|

558.8 |

|

520.7 |

| 30 x 20 |

|

508.0 |

|

508.0 |

| 30 x 18 |

|

457.2 |

|

495.3 |

| 30 x 16 |

|

406.4 |

|

482.6 |

| 30 x 14 |

|

355.6 |

|

482.6 |

| 30 x 12 |

|

323.9 |

|

472.6 |

| 30 x 10 |

|

273.1 |

|

460.2 |

| 32 x 32 |

812.8 |

812.8 |

596.9 |

596.9 |

| 32 x 30 |

|

762.0 |

|

584.2 |

| 32 x 28 |

|

711.2 |

|

571.5 |

| 32 x 26 |

|

660.4 |

|

571.5 |

| 32 x 24 |

|

609.6 |

|

558.8 |

| 32 x 22 |

|

558.8 |

|

546.1 |

| 32 x 20 |

|

508.0 |

|

533.4 |

| 32 x 18 |

|

457.2 |

|

520.7 |

| 32 x 16 |

|

406.4 |

|

508.0 |

| 32 x 14 |

|

355.6 |

|

508.0 |

| 34 x 34 |

863.6 |

863.6 |

635.0 |

635.0 |

| 34 x 32 |

|

812.8 |

|

622.3 |

| 34 x 30 |

|

762.0 |

|

609.6 |

| 34 x 28 |

|

711.2 |

|

596.9 |

| 34 x 26 |

|

660.4 |

|

596.9 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 34 x 24 |

|

609.6 |

|

584.2 |

| 34 x 22 |

|

558.8 |

|

571.5 |

| 34 x 20 |

|

508.0 |

|

558.8 |

| 34 x 18 |

|

457.2 |

|

546.1 |

| 34 x 16 |

|

406.4 |

|

533.4 |

| 36 x 36 |

914.4 |

914.4 |

673.1 |

673.1 |

| 36 x 34 |

|

863.6 |

|

660.4 |

| 36 x 32 |

|

812.8 |

|

647.7 |

| 36 x 30 |

|

762.0 |

|

635.0 |

| 36 x 28 |

|

711.2 |

|

622.3 |

| 36 x 26 |

|

660.4 |

|

622.3 |

| 36 x 24 |

|

609.6 |

|

609.6 |

| 36 x 22 |

|

558.8 |

|

596.9 |

| 36 x 20 |

|

508.0 |

|

584.2 |

| 36 x 18 |

|

457.2 |

|

571.5 |

| 36 x 16 |

|

406.4 |

|

558.8 |

| 38 x 38 |

965.2 |

965.2 |

711.2 |

711.2 |

| 38 x 36 |

|

914.4 |

|

711.2 |

| 38 x 34 |

|

863.6 |

|

698.5 |

| 38 x 32 |

|

812.8 |

|

685.8 |

| 38 x 30 |

|

762.0 |

|

673.1 |

| 38 x 28 |

|

711.2 |

|

647.7 |

| 38 x 26 |

|

660.4 |

|

647.7 |

| 38 x 24 |

|

609.6 |

|

635.0 |

| 38 x 22 |

|

558.8 |

|

622.3 |

| 38 x 20 |

|

508.0 |

|

609.6 |

| 38 x 18 |

|

457.2 |

|

596.9 |

| 40 x 40 |

1016.0 |

1016.0 |

749.3 |

749.3 |

| 40 x 38 |

|

965.2 |

|

749.3 |

| 40 x 36 |

|

914.4 |

|

736.6 |

| 40 x 34 |

|

863.6 |

|

723.9 |

| 40 x 32 |

|

812.8 |

|

711.2 |

| 40 x 30 |

|

762.0 |

|

698.5 |

| 40 x 28 |

|

711.2 |

|

673.1 |

| 40 x 26 |

|

660.4 |

|

673.1 |

| 40 x 24 |

|

609.6 |

|

660.4 |

| 40 x 22 |

|

558.8 |

|

647.7 |

| 40 x 20 |

|

508.0 |

|

635.0 |

| 40 x 18 |

|

457.2 |

|

622.3 |

| 42 x 42 |

1066.8 |

1066.8 |

762.0 |

711.2 |

| 42 x 40 |

|

1016.0 |

|

711.2 |

ANSI B16.9 / MSS SP-75 Equal Tee/Reducing Tee Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter At Bevel D |

Center to End |

| Run |

Outlet |

Run C |

Outlet (1) M |

| 42 x 38 |

|

965.2 |

|

711.2 |

| 42 x 36 |

|

914.4 |

|

711.2 |

| 42 x 34 |

|

863.6 |

|

711.2 |

| 42 x 32 |

|

812.8 |

|

711.2 |

| 42 x 30 |

|

762.0 |

|

711.2 |

| 42 x 28 |

1066.8 |

711.2 |

762.0 |

698.5 |

| 42 x 26 |

|

660.4 |

|

698.5 |

| 42 x 24 |

|

609.6 |

|

660.4 |

| 42 x 22 |

|

558.8 |

|

660.4 |

| 42 x 20 |

|

508.0 |

|

660.4 |

| 42 x 18 |

|

457.2 |

|

647.7 |

| 42 x 16 |

|

406.4 |

|

635.0 |

| 44 x 44 |

1117.6 |

1117.6 |

812.8 |

762.0 |

| 44 x 42 |

|

1066.8 |

|

762.0 |

| 44 x 40 |

|

1016.0 |

|

749.3 |

| 44 x 38 |

|

965.2 |

|

736.6 |

| 44 x 36 |

|

914.4 |

|

723.9 |

| 44 x 34 |

|

863.6 |

|

723.9 |

| 44 x 32 |

|

812.8 |

|

711.2 |

| 44 x 30 |

|

762.0 |

|

711.2 |

| 44 x 28 |

|

711.2 |

|

698.5 |

| 44 x 26 |

|

660.4 |

|

698.5 |

| 44 x 24 |

|

609.6 |

|

698.5 |

| 44 x 22 |

|

558.8 |

|

685.8 |

| 44 x 20 |

|

508.0 |

|

685.8 |

| 46 x 46 |

1168.4 |

1168.4 |

850.9 |

800.1 |

| 46 x 44 |

|

1117.6 |

|

800.1 |

| 46 x 42 |

|

1066.8 |

|

787.4 |

| 46 x 40 |

|

1016.0 |

|

774.7 |

| 46 x 38 |

|

965.2 |

|

762.0 |

| 46 x 36 |

|

914.4 |

|

762.0 |

| 46 x 34 |

|

863.6 |

|

749.3 |

| 46 x 32 |

|

812.8 |

|

749.3 |

| 46 x 30 |

|

762.0 |

|

736.6 |

| 46 x 28 |

|

711.2 |

|

736.6 |

| 46 x 26 |

|

660.4 |

|

736.6 |

| 46 x 24 |

|

609.6 |

|

723.9 |

| 46 x 20* |

|

508.0 |

|

723.9 |

| 48 x 48 |

1219.2 |

1219.2 |

889.0 |

838.2 |

| 48 x 46 |

|

1168.4 |

|

838.2 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

1219.2 |

812.8 |

889.0 |

787.4 |

| 48 x 44 |

|

1117.6 |

|

838.2 |

| 48 x 42 |

|

1066.8 |

|

812.8 |

| 48 x 40 |

|

1016.0 |

|

812.8 |

| 48 x 38 |

|

965.2 |

|

812.8 |

| 48 x 36 |

|

914.4 |

|

787.4 |

| 48 x 34 |

|

863.6 |

|

787.4 |

| 48 x 32 |

|

812.8 |

|

787.4 |

| 48 x 30 |

|

762.0 |

|

762.0 |

| 48 x 28 |

|

711.2 |

|

762.0 |

| 48 x 26 |

|

660.4 |

|

762.0 |

| 48 x 24 |

|

609.6 |

|

736.6 |

| 48 x 22 |

|

558.8 |

|

736.6 |

| 52 x 52* |

1320.8 |

1320.8 |

965.2 |

914.4 |

| 52 x 48* |

|

1219.2 |

|

863.6 |

| 52 x 44* |

|

1117.6 |

|

812.8 |

| 52 x 40* |

|

1016.0 |

|

762.0 |

| 54 x 54* |

1371.6 |

1371.6 |

1003.3 |

952.5 |

| 54 x 52* |

|

1320.8 |

|

914.4 |

| 54 x 48* |

|

1219.2 |

|

863.6 |

| 54 x 44* |

|

1117.6 |

|

863.6 |

| 54 x 40* |

|

1016.0 |

|

812.8 |

| 54 x 28* |

|

711.2 |

|

787.4 |

| 54 x 20* |

|

508.0 |

|

787.4 |

| 56 x 56* |

1422.4 |

1422.4 |

1041.4 |

965.2 |

| 56 x 52* |

|

1320.8 |

|

914.4 |

| 56 x 48* |

|

1219.2 |

|

863.6 |

| 56 x 44* |

|

1117.6 |

|

812.8 |

| 56 x 40* |

|

1016.0 |

|

812.8 |

| 56 x 28* |

|

711.2 |

|

812.8 |

| 56 x 20* |

|

508.0 |

|

812.8 |

| 60 x 60* |

1524.0 |

1524.0 |

1117.6 |

1016.0 |

| 60 x 56* |

|

1422.4 |

|

965.2 |

| 60 x 52* |

|

1320.8 |

|

914.4 |

| 60 x 48* |

|

1219.2 |

|

863.6 |

| 60 x 40* |

|

1016.0 |

|

863.6 |

| 60 x 28* |

|

711.2 |

|

863.6 |

| 60 x 20* |

|

508.0 |

|

863.6 |

| 64 x 64* |

1626.0 |

1626.0 |

1194.0 |

1092.0 |

| 64 x 60* |

|

1524.0 |

|

1067.0 |

| 64 x 56* |

|

1422.0 |

|

1016.0 |

| 64 x 52* |

|

1321.0 |

|

965.0 |

| 64 x 48* |

|

1219.0 |

|

914 |

| 66 x 66* |

1676.4 |

1676.4 |

1219.2 |

1066.8 |

| 68 x 68* |

1727.0 |

1727.0 |

1270.0 |

1168.0 |

| 68 x 64* |

|

1626.0 |

|

1143.0 |

| 68 x 60* |

|

1524.0 |

|

1118.0 |

| 68 x 56* |

|

1422.0 |

|

1067.0 |

| 68 x 52* |

|

1321.0 |

|

1016.0 |

| 68 x 48* |

|

1219.0 |

|

965.0 |

| 72 x 72* |

1829.0 |

1829.0 |

1320.0 |

1245.0 |

| 72 x 68* |

|

1727.0 |

|

1219.0 |

| 72 x 64* |

|

1626.0 |

|

1194.0 |

| 72 x 60* |

|

1524.0 |

|

1168.0 |

| 72 x 56* |

1829.0 |

1422.0 |

1320.0 |

1118.0 |

| 72 x 52* |

|

1321.0 |

|

1067.0 |

| 72 x 48* |

|

1219.0 |

|

1016.0 |

| 76 x 76* |

1930.0 |

1930.0 |

1422.0 |

1320.0 |

| 76 x 72* |

|

1829.0 |

|

1295.0 |

| 76 x 68* |

|

1727.0 |

|

1270.0 |

| 76 x 64* |

|

1626.0 |

|

1245.0 |

| 76 x 60* |

|

1524.0 |

|

1219.0 |

| 76 x 56* |

|

1422.0 |

|

1168.0 |

| 76 x 52* |

|

1321.0 |

|

1118.0 |

| 76 x 48* |

|

1219.0 |

|

1067.0 |

| 80 x 80* |

2032.0 |

2032.0 |

1499.0 |

1397.0 |

| 80 x 76* |

|

1930.0 |

|

1372.0 |

| 80 x 72* |

|

1829.0 |

|

1346.0 |

| 80 x 68* |

|

1727.0 |

|

1321.0 |

| 80 x 64* |

|

1626.0 |

|

1295.0 |

| 80 x 60* |

|

1524.0 |

|

1270.0 |

| 80 x 56* |

|

1422.0 |

|

1219.0 |

| 80 x 52* |

|

1321.0 |

|

1168.0 |

| 80 x 48* |

|

1219.0 |

|

1118.0 |

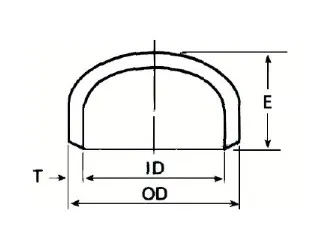

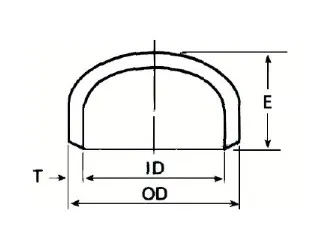

ANSI B16.9 / MSS SP-75 Cap Weight and Dimension Chart (mm, kg)

| Nominal Pipe Size (NPS) |

Outside Diameter at Bevel D |

Center to End E |

| 1/2 |

21.3 |

25.4 |

| 3/4 |

26.7 |

25.4 |

| 1 |

33.4 |

38.1 |

| 1-1/4 |

42.2 |

38.1 |

| 1-1/2 |

48.3 |

38.1 |

| 2 |

60.3 |

38.1 |

| 2-1/2 |

73.0 |

38.1 |

| 3 |

88.9 |

50.8 |

| 3-1/2 |

101.6 |

63.5 |

| 4 |

114.3 |

63.5 |

| 5 |

141.3 |

76.2 |

| 6 |

168.3 |

88.9 |

| 8 |

219.1 |

101.6 |

| 10 |

273.1 |

127.0 |

| 12 |

323.9 |

152.4 |

| 14 |

355.6 |

165.1 |

| 16 |

406.4 |

177.8 |

| 18 |

457.2 |

203.2 |

| 20 |

508.0 |

228.6 |

| 22 |

558.8 |

254.0 |

| 24 |

609.6 |

266.7 |

| 26 |

660.4 |

266.7 |

| 28 |

711.2 |

266.7 |

| 30 |

762.0 |

266.7 |

| 32 |

812.8 |

266.7 |

| 34 |

863.6 |

266.7 |

| 36 |

914.4 |

266.7 |

| 38 |

965.2 |

304.8 |

| 40 |

1016.0 |

304.8 |

| 42 |

1066.8 |

304.8 |

| 44 |

1117.6 |

342.9 |

| 46 |

1168.4 |

342.9 |

| 48 |

1219.2 |

342.9 |

ANSI B36.19M Wall Thickness Schedule Dimension Chart (mm, kg)

| Nominal Pipe Size |

Outside Diameter |

Nominal Wall Thickness |

| A |

B |

JIS |

ANSI |

Sch 5S |

Sch 10S |

Sch 20S |

GS |

Sch 10 |

LG (7.9) |

Sch 20 |

Sch 30 |

STD |

Sch 40 |

Sch 60 |

XS |

Sch 80 |

Sch 100 |

Sch 120 |

Sch 140 |

Sch 160 |

XXS |

| 8 |

1/4 |

13.8 |

13.7 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.2) |

2.2 |

2.4 |

(3.0) |

3.0 |

- |

- |

- |

- |

- |

| 10 |

3/8 |

17.3 |

17.1 |

1.2 |

1.65 |

2.0 |

2.3 |

- |

- |

- |

- |

(2.3) |

2.3 |

2.8 |

(3.2) |

3.2 |

- |

- |

- |

- |

- |

| 15 |

1/2 |

21.7 |

21.3 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.8) |

2.8 |

3.2 |

(3.7) |

3.7 |

- |

- |

- |

4.7 |

7.5 |

| 20 |

3/4 |

27.2 |

26.7 |

1.65 |

2.1 |

2.5 |

2.8 |

- |

- |

- |

- |

(2.9) |

2.9 |

3.4 |

(3.9) |

3.9 |

- |

- |

- |

5.5 |

7.8 |

| 25 |

1 |

34.0 |

33.4 |

1.65 |

2.8 |

3.0 |

3.2 |

- |

- |

- |

- |

(3.4) |

3.4 |

3.9 |

(4.5) |

4.5 |

- |

- |

- |

6.4 |

9.1 |

| 32 |

1-1/4 |

42.7 |

42.2 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.6) |

3.6 |

4.5 |

(4.9) |

4.9 |

- |

- |

- |

6.4 |

9.7 |

| 40 |

1-1/2 |

48.6 |

48.3 |

1.65 |

2.8 |

3.0 |

3.5 |

- |

- |

- |

- |

(3.7) |

3.7 |

4.5 |

(5.1) |

5.1 |

- |

- |

- |

7.1 |

10.2 |

| 50 |

2 |

60.5 |

60.3 |

1.65 |

2.8 |

3.5 |

3.8 |

- |

- |

- |

- |

(3.9) |

3.9 |

4.9 |

(5.5) |

5.5 |

- |

- |

- |

8.7 |

11.1 |

| 65 |

2-1/2 |

76.3 |

73.0 |

2.1 |

3.0 |

3.5 |

4.2 |

- |

- |

- |

- |

(5.2) |

5.2 |

6.0 |

(7.0) |

7.0 |

- |

- |

- |

9.5 |

14.0 |

| 80 |

3 |

89.1 |

88.9 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.5) |

5.5 |

6.6 |

(7.6) |

7.6 |

- |

- |

- |

11.1 |

15.2 |

| 90 |

3-1/2 |

101.6 |

101.6 |

2.1 |

3.0 |

4.0 |

4.2 |

- |

- |

- |

- |

(5.7) |

5.7 |

7.0 |

(8.1) |

8.1 |

- |

- |

- |

12.7 |

- |

| 100 |

4 |

114.3 |

114.3 |

2.1 |

3.0 |

4.0 |

4.5 |

- |

- |

- |

- |

(6.0) |

6.0 |

7.1 |

(8.6) |

8.6 |

- |

11.1 |

- |

13.5 |

17.1 |

| 125 |

5 |

139.8 |

141.3 |

2.8 |

3.4 |

5.0 |

4.5 |

- |

- |

- |

- |

(6.6) |

6.6 |

8.1 |

(9.5) |

9.5 |

- |

12.7 |

- |

15.9 |

19.0 |

| 150 |

6 |

165.2 |

168.3 |

2.8 |

3.4 |

5.0 |

5.0 |

- |

5.0** |

- |

- |

(7.1) |

7.1 |

9.3 |

(11.0) |

11.0 |

- |

14.3 |

- |

18.2 |

21.9 |

| 175 |

7 |

190.7 |

- |

- |

- |

- |

5.3 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 200 |

8 |

216.3 |

219.1 |

2.8 |

3.8 |

6.5 |

5.8 |

- |

5.8** |

6.4 |

7.0 |

(8.2) |

8.2 |

10.3 |

(12.7) |

12.7 |

15.1 |

18.2 |

20.6 |

23.0 |

22.2 |

| 225 |

9 |

241.8 |

- |

- |

- |

- |

6.2 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

| 250 |

10 |

267.4 |

273.1 |

3.4 |

4.2 |

6.5 |

6.6 |

- |

6.6** |

6.4 |

7.8 |

(9.3) |

9.3 |

12.7 |

12.7 |

15.1 |

18.3 |

21.4 |

25.4 |

28.6 |

25.4 |

| 300 |

12 |

318.5 |

323.9 |

4.0 |

4.6 |

6.5 |

6.9 |

- |

6.9** |

6.4 |

8.4 |

9.5 |

10.3 |

14.3 |

12.7 |

17.4 |

21.4 |

25.4 |

28.6 |

33.3 |

25.4 |

| 350 |

14 |

355.6 |

355.6 |

4.0 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

11.1 |

15.1 |

12.7 |

19.0 |

23.8 |

27.8 |

31.8 |

35.7 |

- |

| 400 |

16 |

406.4 |

406.4 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

9.5 |

9.5 |

12.7 |

16.7 |

12.7 |

21.4 |

26.2 |

30.9 |

36.5 |

40.5 |

- |

| 450 |

18 |

457.2 |

457.2 |

4.2 |

4.8 |

7.9 |

7.9 |

6.4 |

7.9 |

7.9 |

11.1 |

9.5 |

14.3 |

19.0 |

12.7 |

23.8 |

29.4 |

34.9 |

39.7 |

45.2 |

- |

| 500 |

20 |

508.0 |

508.0 |

4.8 |

5.5 |

7.9 |

7.9 |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

15.1 |

20.6 |

12.7 |

26.2 |

32.5 |

38.1 |

44.4 |

50.0 |

- |

| 550 |

22 |

558.8 |

558.8 |

4.8 |

5.5 |

- |

- |

6.4 |

7.9 |

9.5 |

12.7 |

9.5 |

- |

22.2 |

12.7 |

28.6 |

34.9 |

41.3 |

47.6 |

54.0 |

- |

| 600 |

24 |

609.6 |

609.6 |

5.5 |

6.4 |

- |

- |

6.4 |

7.9 |

9.5 |

14.3 |

9.5 |

17.5 |

24.6 |

12.7 |

31.0 |

38.9 |

46.0 |

52.4 |

59.5 |

- |

| 650 |

26 |

660.4 |

660.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 700 |

28 |

711.2 |

711.2 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 750 |

30 |

762.0 |

762.0 |

6.4 |

7.9 |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 800 |

32 |

812.8 |

812.8 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 850 |

34 |

863.6 |

863.6 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

17.5 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 900 |

36 |

914.4 |

914.4 |

- |

- |

- |

- |

7.9 |

7.9 |

12.7 |

15.9 |

9.5 |

19.1 |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 950 |

38 |

965.2 |

965.2 |

- |

- |

- |

- |

- |

7.9 |

12.7 |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1000 |

40 |

1016.0 |

1016.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1050 |

42 |

1066.8 |

1066.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1100 |

44 |

1117.6 |

1117.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1150 |

46 |

1168.4 |

1168.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1200 |

48 |

1219.2 |

1219.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1250 |

50 |

1270.0 |

1270.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1300 |

52 |

1320.8 |

1320.8 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1350 |

54 |

1371.6 |

1371.6 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1400 |

56 |

1422.4 |

1422.4 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1450 |

58 |

1473.2 |

1473.2 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1500 |

60 |

1524.0 |

1524.0 |

- |

- |

- |

- |

- |

7.9 |

- |

- |

9.5 |

- |

- |

12.7 |

- |

- |

- |

- |

- |

- |

| 1600 |

64 |

1626.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1700 |

68 |

1727.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1800 |

72 |

1829.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1900 |

76 |

1932.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 2000 |

80 |

2032.0 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Dimensions in accordance with JIS G3448, JIS G3455, JIS G3454, JIS G3459, ANSI B36.10M