ASME B16.11-2011 Alloy Steel Forged Fitting Weight, Dimensions Chart in mm, kg, PDF online

Alloy Steel Forged Fittings is made of carbon, silicon, manganese, tungsten and phosphorus. These

materials composition helps to increase the tensile strength of the fittings by up to 30%, making them

extremely dependable for industrial applications. Chromium is frequently added to the composition,

leading to an increase in corrosion resistance. The amount of chromium depends on the type of alloy

steel forged fitting being manufactured. Finally, sulphur and copper help reduce corrosion and wear

damage. Each element plays a special role in determining the durability and utility of the finished

final product, making it important that only top-quality alloy steel material is used when manufacturing

these useful components. For checking detailed composition, refer to Weight and Dimensions Chart PDF

below.

Alloy steel forged fittings play an important role in piping systems. They are well known for their

superior strength and toughness, making them valuable to various industrial sectors. They possess

excellent impact strength allowing them to handle heavy loads and hold even enormous stress while

providing leak-resistant toughness. In addition, they offer prime mechanical properties at extremely

high and low temperatures, contrary to other traditional fittings. Furthermore, these fittings have

outstanding jerk resistance, ensuring strong operation over time in high-temperature applications.

Consequently, alloy steel forged fittings can be used in many thermal surroundings, including heat

exchangers, furnace tubes and chemical processing equipment. Their elevated corrosion resistance makes

them suitable for offshore oil drilling operations or any applications under extreme environmental

conditions. Overall, alloy steel forged fittings are trusted for long-term performance in stressful

conditions. The Alloy Steel Weight and Dimensions Chart PDF given in mm, kg units below will help you in

selecting appropriate forged fittings for your project requirements.

Alloy Steel Forged Fittings Types

There are two basic types of alloy steel forged fittings, namely:

-

Threaded alloy steel forged fittings - With threaded alloy steel fittings,

pipe and fitting join to each other using threaded sections or parts. Threaded alloy steel forged

fittings Weight Chart is measured in mm, kg. One or both components must be

rotated or revolved to engage the threads and fully close any gap between them. The strength of the

joint depends on the strength of the engaged threads. Threaded pipe forged fittings are proper for

applications such as cooling, fire protection and water distribution. If the pipe system manages

fluids with frequently changing temperatures, threaded pipe fittings are not perfect as temperature

change can cause the fitting to crack in the thread forms.

-

Socket weld alloy steel forged fittings - With socket weld fittings, the

fitting connects to the pipe with pipe entering a shallow hole in the fitting. The gap is then

closed with a “fillet weld” which involves heating and filler metal to provide a seal, metal is

melted and solidified again to close the gap. Socket weld forged fittings may be called to be more

permanent than threaded forged fittings. The drawback of fittings of this type is the time and hard

efforts for installation. Socket weld alloy steel forged fittings Dimensions Chart is given in mm,

kg. Typical applications for socket weld forged fittings include steam and other gases, toxic fluids

and acids, and explosive liquids and gases where highest connection strength and leakage prevention

is necessary.

Alloy steel forged fittings are classified further into:

- Elbows

- Tees

- Crosses

- Couplings

- Reducers

- Caps

- Unions

any many more...

Alloy Steel Forged Fittings Specifications

The ASME B16.11 specifications cover forged fittings to fit ASME B36.10 and ASME B36.19 pipes. This

specification covers the material requirements, dimensions, ratings, marking, and limitations and

strength for socket weld forged fittings and threaded forged fittings. Users should apply B16.11

specifications in conjunction with equipment that other volumes of the ASME B16 series of standards

describe. ASTM A182 is another specification that used for forged pipe fittings. Specifically, ASTM

A182 covers forged fittings, forged or rolled alloy pipe flanges, alloy steel pipe flanges, valves

and other parts for high-temperature service. ASTM A182 also applies to forged fittings for

application in

pressure systems. Alloy Steel Forged Fittings Weight and Dimensions Chart gives you the detailed

specifications.

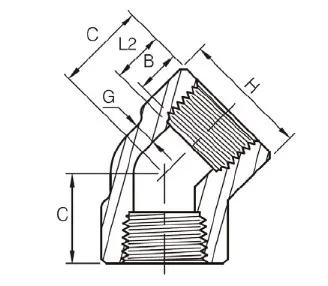

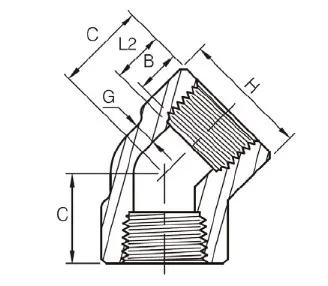

ASME B16.11-2011 Threaded Elbow 45° Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Center to End A |

Outside Diameter Of Band H |

Minimum Wall Thickness G |

Length of Thread(Min) |

| 2M |

3M |

6M |

2M |

3M |

6M |

2M |

3M |

6M |

B(1) |

L2(1) |

| 6 |

1/8” |

17 |

17 |

19 |

22 |

22 |

25 |

3.18 |

3.18 |

6.35 |

6.4 |

6.7 |

| 8 |

1/4” |

17 |

19 |

22 |

22 |

25 |

33 |

3.18 |

3.30 |

6.60 |

8.1 |

10.2 |

| 10 |

3/8” |

19 |

22 |

25 |

25 |

33 |

38 |

3.18 |

3.51 |

6.98 |

9.1 |

10.4 |

| 15 |

1/2” |

22 |

25 |

28 |

33 |

38 |

46 |

3.18 |

4.09 |

8.15 |

10.9 |

13.6 |

| 20 |

3/4” |

25 |

28 |

33 |

38 |

46 |

56 |

3.18 |

4.32 |

8.53 |

12.7 |

13.9 |

| 25 |

1” |

28 |

33 |

35 |

46 |

56 |

62 |

3.68 |

4.98 |

9.93 |

14.7 |

17.3 |

| 32 |

1-1/4” |

33 |

35 |

43 |

56 |

62 |

75 |

3.89 |

5.28 |

10.59 |

17.0 |

18.0 |

| 40 |

1-1/2” |

35 |

43 |

44 |

62 |

75 |

84 |

4.01 |

5.56 |

11.07 |

17.8 |

18.4 |

| 50 |

2” |

43 |

44 |

52 |

75 |

84 |

102 |

4.27 |

7.14 |

12.09 |

19.0 |

19.2 |

| 65 |

2-1/2” |

52 |

52 |

64 |

92 |

102 |

121 |

5.61 |

7.65 |

15.29 |

23.6 |

28.9 |

| 80 |

3” |

64 |

64 |

79 |

109 |

121 |

146 |

5.99 |

8.84 |

16.64 |

25.9 |

30.5 |

| 100 |

4” |

79 |

79 |

79 |

146 |

152 |

152 |

6.55 |

11.18 |

18.67 |

27.7 |

33.0 |

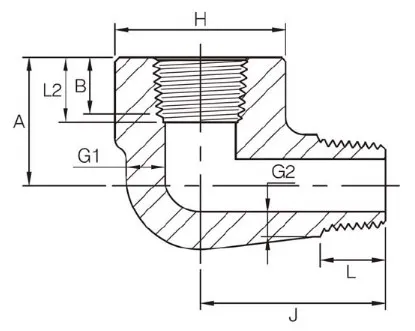

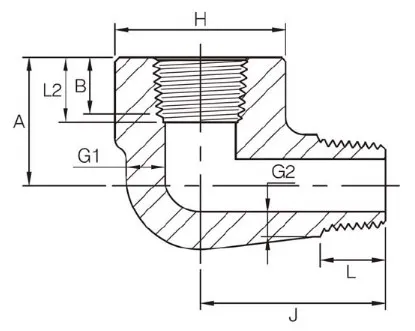

ASME B16.11-2011 Threaded Street Elbow Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

H |

A |

J |

G1(Min) |

G2(1)(Min) |

B(2)(Min) |

L2(2)(Min) |

L (Min) |

| 3M |

6M |

3M |

6M |

3M |

6M |

3M |

6M |

3M |

6M |

| 6 |

1/8” |

19 |

25 |

19 |

22 |

25 |

32 |

3.18 |

5.08 |

2.74 |

4.22 |

6.4 |

6.7 |

10.0 |

| 8 |

1/4” |

25 |

32 |

22 |

25 |

32 |

38 |

3.30 |

5.66 |

3.22 |

5.28 |

8.1 |

10.2 |

11.0 |

| 10 |

3/8” |

32 |

38 |

25 |

28 |

38 |

41 |

3.50 |

6.98 |

3.50 |

5.59 |

9.1 |

10.4 |

13.0 |

| 15 |

1/2” |

38 |

44 |

28 |

35 |

41 |

48 |

4.09 |

8.15 |

4.16 |

6.53 |

10.9 |

13.6 |

14.0 |

| 20 |

3/4” |

44 |

51 |

35 |

44 |

48 |

57 |

4.32 |

8.53 |

4.88 |

6.86 |

12.7 |

13.9 |

16.0 |

| 25 |

1” |

51 |

62 |

44 |

51 |

57 |

66 |

4.98 |

9.93 |

5.56 |

7.95 |

14.7 |

17.3 |

19.0 |

| 32 |

1-1/4” |

62 |

70 |

51 |

54 |

66 |

71 |

5.28 |

10.59 |

5.56 |

8.48 |

17.0 |

18.0 |

21.0 |

| 40 |

1-1/2” |

70 |

84 |

54 |

64 |

71 |

84 |

5.56 |

11.07 |

6.25 |

8.89 |

17.8 |

18.4 |

21.0 |

| 50 |

2” |

84 |

102 |

64 |

83 |

84 |

105 |

7.14 |

12.09 |

7.64 |

9.70 |

19.0 |

19.0 |

22.0 |

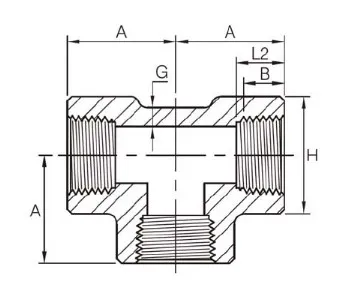

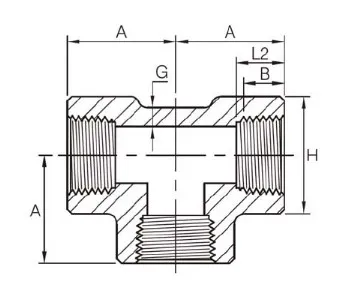

ASME B16.11-2011 Threaded Tee Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Center to End A |

Outside Diameter Of Band H |

Minimum Wall Thickness G |

Length of Thread(Min) |

| 2M |

3M |

6M |

2M |

3M |

6M |

2M |

3M |

6M |

B(1) |

L2(1) |

| 6 |

1/8” |

21 |

21 |

25 |

22 |

22 |

25 |

3.18 |

3.18 |

6.35 |

6.4 |

6.7 |

| 8 |

1/4” |

21 |

25 |

28 |

22 |

25 |

33 |

3.18 |

3.30 |

6.60 |

8.1 |

10.2 |

| 10 |

3/8” |

25 |

28 |

33 |

25 |

33 |

38 |

3.18 |

3.51 |

6.98 |

9.1 |

10.4 |

| 15 |

1/2” |

28 |

33 |

38 |

33 |

38 |

46 |

3.18 |

4.09 |

8.15 |

10.9 |

13.6 |

| 20 |

3/4” |

33 |

38 |

44 |

38 |

46 |

56 |

3.18 |

4.32 |

8.53 |

12.7 |

13.9 |

| 25 |

1” |

38 |

44 |

51 |

46 |

56 |

62 |

3.68 |

4.98 |

9.93 |

14.7 |

17.3 |

| 32 |

1-1/4” |

44 |

51 |

60 |

56 |

62 |

75 |

3.89 |

5.28 |

10.59 |

17.0 |

18.0 |

| 40 |

1-1/2” |

51 |

60 |

64 |

62 |

75 |

84 |

4.01 |

5.56 |

11.07 |

17.8 |

18.4 |

| 50 |

2” |

60 |

64 |

83 |

75 |

84 |

102 |

4.27 |

7.14 |

12.09 |

19.0 |

19.2 |

| 65 |

2-1/2” |

76 |

83 |

95 |

92 |

102 |

121 |

5.61 |

7.65 |

15.29 |

23.6 |

28.9 |

| 80 |

3” |

86 |

95 |

106 |

109 |

121 |

146 |

5.99 |

8.84 |

16.64 |

25.9 |

30.5 |

| 100 |

4” |

106 |

114 |

114 |

146 |

152 |

152 |

6.55 |

11.18 |

18.67 |

27.7 |

33.0 |

ASME B16.11-2011 Threaded 45° Lateral Tee Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

A |

E |

G (Min) |

H |

Length of Thread(Min) |

| 2000Lb |

3000Lb |

2000Lb |

3000Lb |

2000Lb |

3000Lb |

2000Lb |

3000Lb |

B(1) |

L2(1) |

| 1/2” |

46 |

55 |

20 |

23 |

3.18 |

4.09 |

33 |

38 |

10.9 |

13.6 |

| 3/4” |

55 |

65 |

23 |

26 |

3.18 |

4.32 |

38 |

46 |

12.7 |

13.9 |

| 1” |

65 |

73 |

26 |

31 |

3.68 |

4.98 |

46 |

56 |

14.7 |

17.3 |

| 1-1/4” |

73 |

82 |

31 |

35 |

3.89 |

5.28 |

56 |

62 |

17.0 |

18.0 |

| 1-1/2” |

82 |

113 |

35 |

42 |

4.01 |

5.56 |

62 |

75 |

17.8 |

18.4 |

| 2” |

113 |

136 |

42 |

56 |

4.27 |

7.14 |

75 |

84 |

19.0 |

19.2 |

| 2-1/2” |

136 |

- |

56 |

- |

5.61 |

- |

92 |

- |

23.6 |

28.9 |

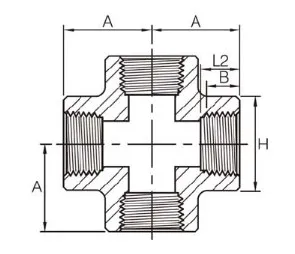

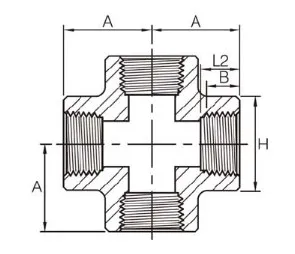

ASME B16.11-2011 Threaded Cross Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Center to End A |

Outside Diameter Of Band H |

Minimum Wall Thickness G |

Length of Thread(Min) |

| 2M |

3M |

6M |

2M |

3M |

6M |

2M |

3M |

6M |

B(1) |

L2(1) |

| 6 |

1/8” |

21 |

21 |

25 |

22 |

22 |

25 |

3.18 |

3.18 |

6.35 |

6.4 |

6.7 |

| 8 |

1/4” |

21 |

25 |

28 |

22 |

25 |

33 |

3.18 |

3.30 |

6.60 |

8.1 |

10.2 |

| 10 |

3/8” |

25 |

28 |

33 |

25 |

33 |

38 |

3.18 |

3.51 |

6.98 |

9.1 |

10.4 |

| 15 |

1/2” |

28 |

33 |

38 |

33 |

38 |

46 |

3.18 |

4.09 |

8.15 |

10.9 |

13.6 |

| 20 |

3/4” |

33 |

38 |

44 |

38 |

46 |

56 |

3.18 |

4.32 |

8.53 |

12.7 |

13.9 |

| 25 |

1” |

38 |

44 |

51 |

46 |

56 |

62 |

3.68 |

4.98 |

9.93 |

14.7 |

17.3 |

| 32 |

1-1/4” |

44 |

51 |

60 |

56 |

62 |

75 |

3.89 |

5.28 |

10.59 |

17.0 |

18.0 |

| 40 |

1-1/2” |

51 |

60 |

64 |

62 |

75 |

84 |

4.01 |

5.56 |

11.07 |

17.8 |

18.4 |

| 50 |

2” |

60 |

64 |

83 |

75 |

84 |

102 |

4.27 |

7.14 |

12.09 |

19.0 |

19.2 |

| 65 |

2-1/2” |

76 |

83 |

95 |

92 |

102 |

121 |

5.61 |

7.65 |

15.29 |

23.6 |

28.9 |

| 80 |

3” |

86 |

95 |

106 |

109 |

121 |

146 |

5.99 |

8.84 |

16.64 |

25.9 |

30.5 |

| 100 |

4” |

106 |

114 |

114 |

146 |

152 |

152 |

6.55 |

11.18 |

18.67 |

27.7 |

33.0 |

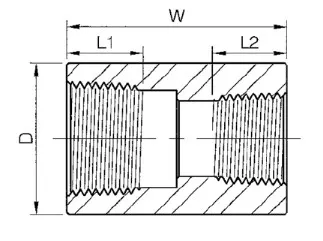

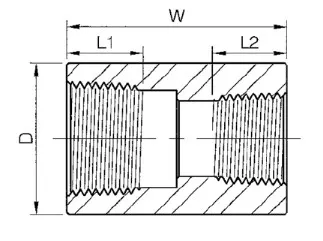

ASME B16.11-2011 Threaded Full Coupling Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

End to End Coupling W |

Outside Diameter D |

Length of Thread (Min) |

| 3000Lb |

6000Lb |

B(1) |

L2(1) |

| 6 |

1/8” |

32 |

16 |

22 |

6.4 |

6.7 |

| 8 |

1/4” |

35 |

19 |

25 |

8.1 |

10.2 |

| 10 |

3/8” |

38 |

22 |

32 |

9.1 |

10.4 |

| 15 |

1/2” |

48 |

28 |

38 |

10.9 |

13.6 |

| 20 |

3/4” |

51 |

35 |

44 |

12.7 |

13.9 |

| 25 |

1” |

60 |

44 |

57 |

14.7 |

17.3 |

| 32 |

1-1/4” |

67 |

57 |

64 |

17.0 |

18.0 |

| 40 |

1-1/2” |

79 |

64 |

76 |

17.8 |

18.4 |

| 50 |

2” |

86 |

76 |

92 |

19.0 |

19.2 |

| 65 |

2-1/2” |

92 |

92 |

108 |

23.6 |

28.9 |

| 80 |

3” |

108 |

108 |

127 |

25.9 |

30.5 |

| 100 |

4” |

121 |

140 |

159 |

27.7 |

33.0 |

ASME B16.11-2011 Threaded Half Coupling Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

End to End Coupling W |

Outside Diameter D |

Length of Thread (Min) |

| 3000Lb |

6000Lb |

B(1) |

L2(1) |

| 6 |

1/8” |

32 |

16 |

22 |

6.4 |

6.7 |

| 8 |

1/4” |

35 |

19 |

25 |

8.1 |

10.2 |

| 10 |

3/8” |

38 |

22 |

32 |

9.1 |

10.4 |

| 15 |

1/2” |

48 |

28 |

38 |

10.9 |

13.6 |

| 20 |

3/4” |

51 |

35 |

44 |

12.7 |

13.9 |

| 25 |

1” |

60 |

44 |

57 |

14.7 |

17.3 |

| 32 |

1-1/4” |

67 |

57 |

64 |

17.0 |

18.0 |

| 40 |

1-1/2” |

79 |

64 |

76 |

17.8 |

18.4 |

| 50 |

2” |

86 |

76 |

92 |

19.0 |

19.2 |

| 65 |

2-1/2” |

92 |

92 |

108 |

23.6 |

28.9 |

| 80 |

3” |

108 |

108 |

127 |

25.9 |

30.5 |

| 100 |

4” |

121 |

140 |

159 |

27.7 |

33.0 |

ASME B16.11-2011 Threaded Reducing Coupling Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

D |

W |

L1 |

L2 |

| 3000Lb |

6000Lb |

| 1/4”x1/8” |

19.0 |

25.0 |

35.0 |

11.4 |

8.8 |

| 3/8”x1/8” |

22.0 |

32.0 |

38.0 |

12.4 |

8.8 |

| 3/8”x1/4” |

22.0 |

32.0 |

38.0 |

12.4 |

11.4 |

| 1/2”x1/8” |

28.0 |

38.0 |

48.0 |

14.9 |

8.8 |

| 1/2”x1/4” |

28.0 |

38.0 |

48.0 |

14.9 |

11.4 |

| 1/2”x3/8” |

28.0 |

38.0 |

48.0 |

14.9 |

12.4 |

| 3/4”x1/8” |

35.0 |

44.0 |

51.0 |

16.8 |

8.8 |

| 3/4”x1/4” |

35.0 |

44.0 |

51.0 |

16.8 |

11.4 |

| 3/4”x3/8” |

35.0 |

44.0 |

51.0 |

16.8 |

12.4 |

| 3/4”x1/2” |

35.0 |

44.0 |

51.0 |

16.8 |

14.9 |

| 1”x1/8” |

44.0 |

57.0 |

51.0 |

19.6 |

8.8 |

| 1x1/4” |

44.0 |

57.0 |

60.0 |

19.6 |

11.4 |

| 1”x3/8” |

44.0 |

57.0 |

60.0 |

19.6 |

12.4 |

| 1”x1/2” |

44.0 |

57.0 |

60.0 |

19.6 |

14.9 |

| 1”x3/4” |

44.0 |

57.0 |

60.0 |

19.6 |

16.8 |

| 1-1/4”x1/8” |

57.0 |

64.0 |

67.0 |

21.9 |

8.8 |

| 1-1/4”x1/4” |

57.0 |

64.0 |

67.0 |

21.9 |

11.4 |

| 1-1/4”x3/8” |

57.0 |

64.0 |

67.0 |

21.9 |

12.4 |

| 1-1/4”x1/2” |

57.0 |

64.0 |

67.0 |

21.9 |

14.9 |

| 1-1/4”x3/4” |

57.0 |

64.0 |

67.0 |

21.9 |

16.8 |

| 1-1/4”x1” |

57.0 |

64.0 |

67.0 |

21.9 |

19.6 |

| 1-1/2”x1/8” |

64.0 |

76.0 |

79.0 |

22.7 |

8.8 |

| 1-1/2”x1/4” |

64.0 |

76.0 |

79.0 |

22.7 |

11.4 |

| 1-1/2”x3/8” |

64.0 |

76.0 |

79.0 |

22.7 |

12.4 |

| 1-1/2”x1/2” |

64.0 |

76.0 |

79.0 |

22.7 |

14.9 |

| 1-1/2”x3/4” |

64.0 |

76.0 |

79.0 |

22.7 |

16.8 |

| 1-1/2”x1” |

64.0 |

76.0 |

79.0 |

22.7 |

19.6 |

| 1-1/2”x1-1/4” |

64.0 |

76.0 |

79.0 |

22.7 |

21.9 |

| 2”x1/8” |

76.0 |

92.0 |

86.0 |

23.9 |

8.8 |

| 2”x1/4” |

76.0 |

92.0 |

86.0 |

23.9 |

11.4 |

| 2”x3/8” |

76.0 |

92.0 |

86.0 |

23.9 |

12.4 |

| 2”x1/2” |

76.0 |

92.0 |

86.0 |

23.9 |

14.9 |

| 2”x3/4” |

76.0 |

92.0 |

86.0 |

23.9 |

16.8 |

| 2”x1” |

76.0 |

92.0 |

86.0 |

23.9 |

19.6 |

| 2”x1-1/4” |

76.0 |

92.0 |

86.0 |

23.9 |

21.9 |

| 2”x1-1/2” |

76.0 |

92.0 |

86.0 |

23.9 |

22.7 |

| 2-1/2”x1/8” |

92.0 |

108.0 |

92.0 |

30.5 |

8.8 |

| 2-1/2”x1/4” |

92.0 |

108.0 |

92.0 |

30.5 |

11.4 |

| 2-1/2”x3/8” |

92.0 |

108.0 |

92.0 |

30.5 |

12.4 |

| 2-1/2”x1/2” |

92.0 |

108.0 |

92.0 |

30.5 |

14.9 |

| 2-1/2”x3/4” |

92.0 |

108.0 |

92.0 |

30.5 |

16.8 |

| 2-1/2”x1” |

92.0 |

108.0 |

92.0 |

30.5 |

19.6 |

| 2-1/2”x1-1/4” |

92.0 |

108.0 |

92.0 |

30.5 |

21.9 |

| 2-1/2”x1-1/2” |

92.0 |

108.0 |

92.0 |

30.5 |

22.7 |

| 2-1/2”x2” |

92.0 |

108.0 |

92.0 |

30.5 |

23.9 |

| 3”x1/8” |

108.0 |

127.0 |

108.0 |

32.8 |

8.8 |

| 3”x1/4” |

108.0 |

127.0 |

108.0 |

32.8 |

11.4 |

| 3”x3/8” |

108.0 |

127.0 |

108.0 |

32.8 |

12.4 |

| 3”x1/2” |

108.0 |

127.0 |

108.0 |

32.8 |

14.9 |

| 3”x3/4” |

108.0 |

127.0 |

108.0 |

32.8 |

16.8 |

| 3”x1” |

108.0 |

127.0 |

108.0 |

32.8 |

19.6 |

| 3”x1-1/4” |

108.0 |

127.0 |

108.0 |

32.8 |

21.9 |

| 3”x1-1/2” |

108.0 |

127.0 |

108.0 |

32.8 |

22.7 |

| 3”x2” |

108.0 |

127.0 |

108.0 |

32.8 |

23.9 |

| 3”x2-1/2” |

108.0 |

127.0 |

108.0 |

32.8 |

30.5 |

| 4”x1/8” |

140.0 |

159.0 |

121.0 |

34.6 |

8.8 |

| 4”x1/4” |

140.0 |

159.0 |

121.0 |

34.6 |

11.4 |

| 4”x3/8” |

140.0 |

159.0 |

121.0 |

34.6 |

12.4 |

| 4”x1/2” |

140.0 |

159.0 |

121.0 |

34.6 |

14.9 |

| 4”x3/4” |

140.0 |

159.0 |

121.0 |

34.6 |

16.8 |

| 4”x1” |

140.0 |

159.0 |

121.0 |

34.6 |

19.6 |

| 4”x1-1/4” |

140.0 |

159.0 |

121.0 |

34.6 |

21.9 |

| 4”x1-1/2” |

140.0 |

159.0 |

121.0 |

34.6 |

22.7 |

| 4”x2” |

140.0 |

159.0 |

121.0 |

34.6 |

23.9 |

| 4”x2-1/2” |

140.0 |

159.0 |

121.0 |

34.6 |

30.5 |

| 4”x3” |

140.0 |

159.0 |

121.0 |

34.6 |

32.8 |

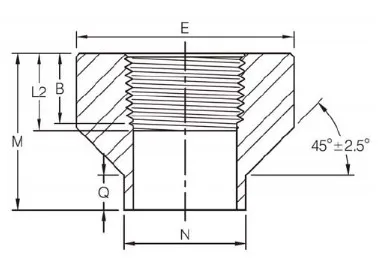

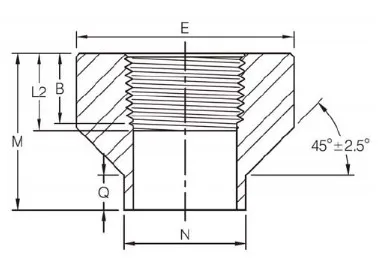

ASME B16.11-2011 Threaded Couplet Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

N |

Q |

M |

E |

Length of Thread (Min) |

| 3000Lb |

6000Lb |

B(1) |

L2(1) |

| 8 |

1/4” |

17.5 |

9.5 |

30.2 |

23.8 |

25.4 |

8.1 |

10.2 |

| 10 |

3/8” |

20.7 |

9.5 |

30.2 |

27.0 |

31.8 |

9.1 |

10.4 |

| 15 |

1/2” |

23.8 |

9.5 |

33.4 |

33.4 |

38.1 |

10.9 |

13.6 |

| 20 |

3/4” |

27.0 |

9.5 |

34.9 |

38.1 |

44.5 |

12.7 |

13.9 |

| 25 |

1” |

33.4 |

9.5 |

42.9 |

46.1 |

57.2 |

14.7 |

17.3 |

| 32 |

1-1/4” |

42.9 |

9.5 |

47.6 |

55.6 |

63.5 |

17.0 |

18.0 |

| 40 |

1-1/2” |

49.2 |

9.5 |

50.8 |

63.5 |

76.2 |

17.8 |

18.4 |

| 50 |

2” |

61.9 |

9.5 |

57.2 |

79.4 |

92.1 |

19.0 |

19.2 |

| 65 |

2-1/2” |

73.0 |

9.5 |

63.5 |

92.1 |

108.0 |

23.6 |

28.9 |

| 80 |

3” |

88.9 |

9.5 |

69.9 |

111.1 |

127.0 |

25.9 |

30.5 |

| 100 |

4” |

114.3 |

9.5 |

76.2 |

141.3 |

158.8 |

27.7 |

33.0 |

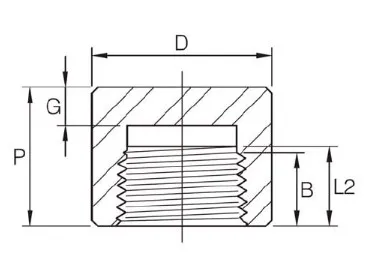

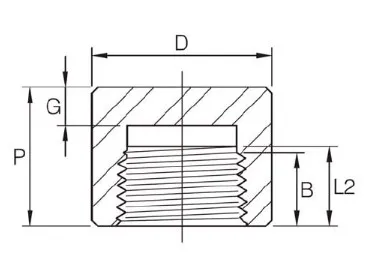

ASME B16.11-2011 Threaded Cap Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

End to End P

|

Outside Diameter D

|

End Wall Thickness G (Min) |

Length of Thread (Min) |

| 3000Lb |

6000Lb |

3000Lb |

6000Lb |

3000Lb |

6000Lb |

B(1) |

L2(1) |

| 6 |

1/8” |

19 |

- |

16 |

- |

4.8 |

- |

6.4 |

6.7 |

| 8 |

1/4” |

25 |

27 |

19 |

25 |

4.8 |

6.4 |

8.1 |

10.2 |

| 10 |

3/8” |

25 |

27 |

22 |

32 |

4.8 |

6.4 |

9.1 |

10.4 |

| 15 |

1/2” |

32 |

33 |

28 |

38 |

6.4 |

7.9 |

10.9 |

13.6 |

| 20 |

3/4” |

37 |

38 |

35 |

44 |

6.4 |

7.9 |

12.7 |

13.9 |

| 25 |

1” |

41 |

43 |

44 |

57 |

9.7 |

11.2 |

14.7 |

17.3 |

| 32 |

1-1/4” |

44 |

46 |

57 |

64 |

9.7 |

11.2 |

17.0 |

18.0 |

| 40 |

1-1/2” |

44 |

48 |

64 |

76 |

11.2 |

12.7 |

17.8 |

18.4 |

| 50 |

2” |

48 |

51 |

76 |

92 |

12.7 |

15.7 |

19.0 |

19.2 |

| 65 |

2-1/2” |

60 |

64 |

92 |

108 |

15.7 |

19.0 |

23.6 |

28.9 |

| 80 |

3” |

65 |

68 |

108 |

127 |

19.0 |

22.4 |

25.9 |

30.5 |

| 100 |

4” |

68 |

75 |

140 |

159 |

22.4 |

28.4 |

27.7 |

33.0 |

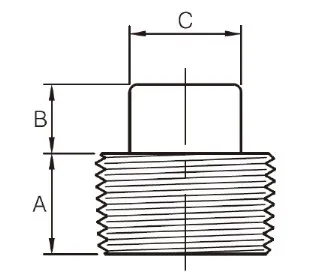

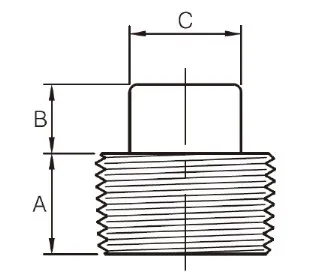

ASME B16.11-2011 Threaded Square Head Plug Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Length (Min) A |

Height of Square (Min) B |

Width Flat (Min) C |

| 6 |

1/8” |

10 |

6 |

7.15 |

| 8 |

1/4” |

11 |

6 |

9.55 |

| 10 |

3/8” |

13 |

8 |

11.11 |

| 15 |

1/2” |

14 |

10 |

14.29 |

| 20 |

3/4” |

16 |

11 |

15.88 |

| 25 |

1” |

19 |

13 |

20.64 |

| 32 |

1-1/4” |

21 |

14 |

23.81 |

| 40 |

1-1/2” |

21 |

16 |

28.58 |

| 50 |

2” |

22 |

18 |

33.34 |

| 65 |

2-1/2” |

27 |

19 |

38.10 |

| 80 |

3” |

28 |

21 |

42.86 |

| 100 |

4” |

32 |

25 |

63.50 |

ASME B16.11-2011 Threaded Round Head Plug Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Diameter of Head (Nom.) E |

Length (Min) D |

| 6 |

1/8” |

10 |

35 |

| 8 |

1/4” |

14 |

41 |

| 10 |

3/8” |

18 |

41 |

| 15 |

1/2” |

21 |

44 |

| 20 |

3/4” |

27 |

44 |

| 25 |

1” |

33 |

51 |

| 32 |

1-1/4” |

43 |

51 |

| 40 |

1-1/2” |

48 |

51 |

| 50 |

2” |

60 |

64 |

| 65 |

2-1/2” |

73 |

70 |

| 80 |

3” |

89 |

70 |

| 100 |

4” |

114 |

76 |

ASME B16.11-2011 Threaded Hex Head Plug Weight and Dimension Chart (mm, kg)

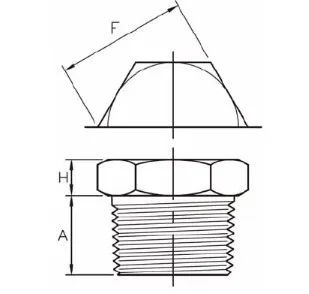

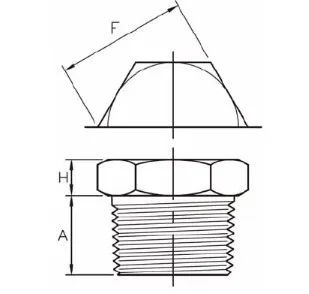

| DN |

Nom. Pipe Size |

Length (Min) A |

Width Flat (Nom.) F |

Hex Height (Min) H |

| 6 |

1/8” |

10 |

11.11 |

6 |

| 8 |

1/4” |

11 |

15.88 |

6 |

| 10 |

3/8” |

13 |

17.46 |

8 |

| 15 |

1/2” |

14 |

22.23 |

8 |

| 20 |

3/4” |

16 |

26.99 |

10 |

| 25 |

1” |

19 |

34.93 |

10 |

| 32 |

1-1/4” |

21 |

44.45 |

14 |

| 40 |

1-1/2” |

21 |

50.80 |

16 |

| 50 |

2” |

22 |

63.50 |

18 |

| 65 |

2-1/2” |

27 |

76.20 |

19 |

| 80 |

3” |

28 |

88.90 |

21 |

| 100 |

4” |

32 |

117.48 |

25 |

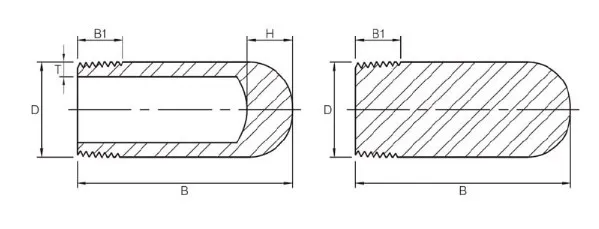

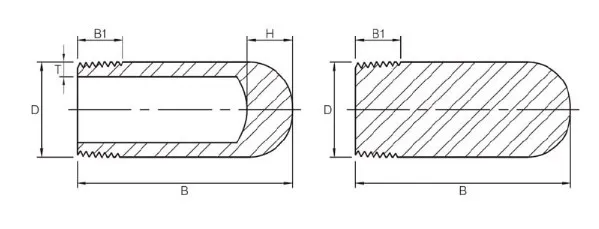

ASME B16.11-2011 Threaded Bull Plug Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

D |

B |

B1 |

T (Min) |

H |

| Sch40/STD |

Sch80/XS (3M) |

Sch160 (6M) |

XXS |

| 1/8” |

10.3 |

51 |

9.5 |

1.73 |

2.41 |

- |

- |

14 |

| 1/4” |

13.7 |

51 |

11.0 |

2.24 |

3.02 |

- |

- |

14 |

| 3/8” |

17.1 |

57 |

12.5 |

2.31 |

3.20 |

- |

- |

14 |

| 1/2” |

21.3 |

64 |

14.5 |

2.77 |

3.73 |

4.78 |

7.47 |

14 |

| 3/4” |

26.7 |

70 |

16.0 |

2.87 |

3.91 |

5.56 |

7.82 |

18 |

| 1” |

33.4 |

76 |

19.0 |

3.38 |

4.55 |

6.35 |

9.09 |

18 |

| 1-1/4” |

42.2 |

83 |

20.5 |

3.56 |

4.85 |

6.35 |

9.70 |

18 |

| 1-1/2” |

48.3 |

89 |

20.5 |

3.68 |

5.08 |

7.14 |

10.15 |

18 |

| 2” |

60.3 |

102 |

22.0 |

3.91 |

5.54 |

8.74 |

11.07 |

20 |

| 2-1/2” |

73.0 |

127 |

27.0 |

5.16 |

7.01 |

9.53 |

14.02 |

20 |

| 3” |

88.9 |

152 |

28.5 |

5.49 |

7.62 |

11.13 |

15.24 |

20 |

| 4” |

114.3 |

178 |

32.0 |

6.02 |

8.56 |

13.49 |

17.12 |

20 |

1. Wall thickness (T Min.) in accordance with ASME

B36.10M.

2. Dimensions in accordance with MSS SP-95-2006.

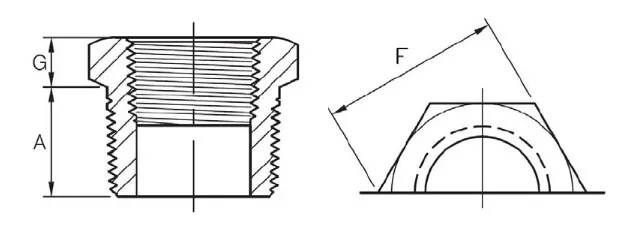

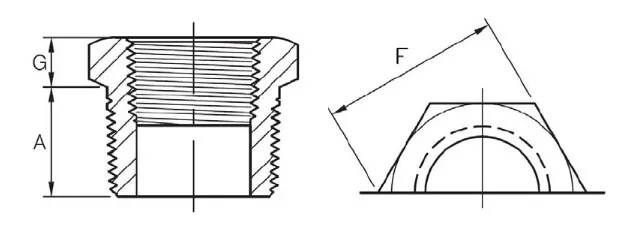

ASME B16.11-2011 Threaded Hex Head Bushing Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Length (Min) A |

Width Flat (Nom.) F |

Hex Height (Min) G |

| 8 |

1/4” |

11 |

15.88 |

3 |

| 10 |

3/8” |

13 |

17.46 |

4 |

| 15 |

1/2” |

14 |

22.23 |

5 |

| 20 |

3/4” |

16 |

26.99 |

6 |

| 25 |

1” |

19 |

34.93 |

6 |

| 32 |

1-1/4” |

21 |

44.45 |

7 |

| 40 |

1-1/2” |

21 |

50.80 |

8 |

| 50 |

2” |

22 |

63.50 |

9 |

| 65 |

2-1/2” |

27 |

76.20 |

10 |

| 80 |

3” |

28 |

88.90 |

10 |

| 100 |

4” |

32 |

117.48 |

13 |

ASME B16.11-2011 Threaded Boss Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

D |

W |

L2 (min) |

| 3000Lb |

3000Lb |

3000Lb |

3000Lb |

3000Lb |

3000Lb |

| 6 |

1/8” |

16.0 |

22.0 |

38.0 |

6.70 |

| 8 |

1/4” |

19.0 |

26.0 |

41.0 |

10.21 |

| 10 |

3/8” |

22.0 |

32.0 |

45.0 |

10.36 |

| 15 |

1/2” |

29.0 |

38.0 |

51.0 |

13.56 |

| 20 |

3/4” |

35.0 |

45.0 |

51.0 |

13.86 |

| 25 |

1” |

45.0 |

60.0 |

51.0 |

17.34 |

| 40 |

1-1/2” |

64.0 |

76.0 |

51.0 |

18.38 |

| 50 |

2” |

76.0 |

95.0 |

51.0 |

19.22 |

Dimensions in accordance with BS3799-1974.

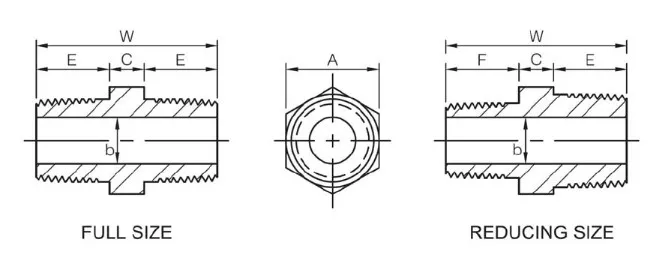

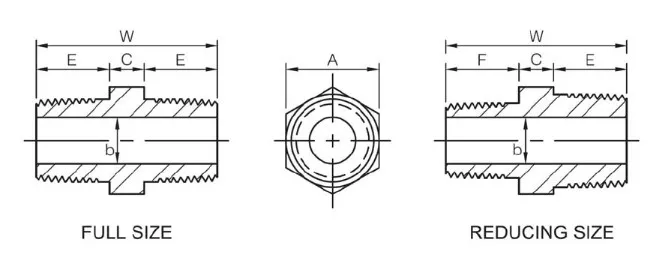

ASME B16.11-2011 Threaded Hex Nipple Bushing Weight and Dimension Chart (mm, kg)

| Nominal Size |

A(min) |

W |

E |

b |

C(min) |

F(min) |

| DN |

Inch |

3000Lb |

6000Lb |

| 6 |

1/8” |

11 |

26 |

10 |

5 |

2 |

6 |

- |

| 8 |

1/4” |

15 |

36 |

15 |

8 |

6 |

6 |

- |

| 8x6 |

1/4”x1/8” |

15 |

31 |

15 |

5 |

2 |

6 |

10 |

| 10 |

3/8” |

18 |

40 |

16 |

11 |

8 |

8 |

- |

| 10x8 |

3/8”x1/4” |

18 |

39 |

16 |

8 |

6 |

8 |

15 |

| 15 |

1/2” |

22 |

48 |

20 |

14 |

11 |

8 |

- |

| 15x10 |

1/2”x3/8” |

22 |

44 |

20 |

11 |

8 |

8 |

16 |

| 15x8 |

1/2”x1/4” |

22 |

43 |

20 |

8 |

6 |

8 |

15 |

| 20 |

3/4” |

27 |

52 |

21 |

19 |

13 |

10 |

- |

| 20x15 |

3/4”x1/2” |

27 |

50 |

21 |

14 |

11 |

9 |

20 |

| 20x10 |

3/4”x3/8” |

27 |

46 |

21 |

11 |

8 |

9 |

16 |

| 25 |

1” |

35 |

60 |

25 |

24 |

17 |

10 |

- |

| 25x20 |

1”x3/4” |

35 |

56 |

25 |

19 |

13 |

10 |

21 |

| 25x15 |

1”x1/2” |

35 |

55 |

25 |

14 |

11 |

10 |

20 |

| 40 |

1-1/2” |

50 |

68 |

26 |

38 |

30 |

16 |

- |

| 40x25 |

1-1/2”x1” |

50 |

67 |

26 |

24 |

17 |

16 |

25 |

| 40x20 |

1-1/2”x3/4” |

50 |

63 |

26 |

19 |

13 |

16 |

21 |

| 40x15 |

1-1/2”x1/2” |

50 |

62 |

26 |

14 |

11 |

16 |

20 |

| 50 |

2” |

62 |

71 |

27 |

49 |

39 |

17 |

- |

| 50x40 |

2”x1-1/2” |

62 |

70 |

27 |

38 |

30 |

17 |

26 |

| 50x25 |

2”x1” |

62 |

70 |

27 |

24 |

17 |

18 |

25 |

| 50x20 |

2”x3/4” |

62 |

65 |

27 |

19 |

13 |

17 |

21 |

| 50x15 |

2”x1/2” |

62 |

65 |

27 |

14 |

11 |

18 |

20 |

Dimensions in accordance with BS3799-1974.

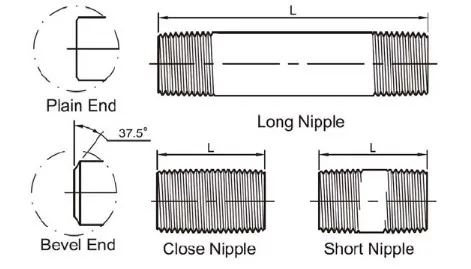

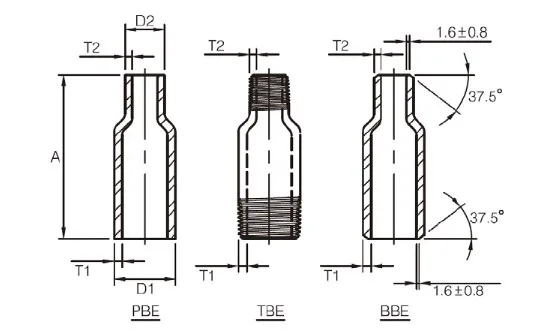

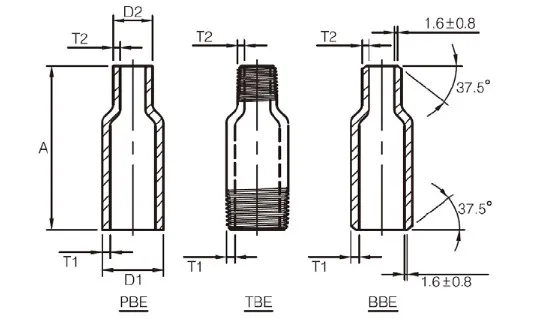

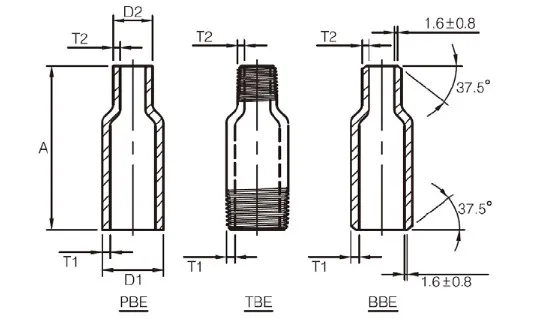

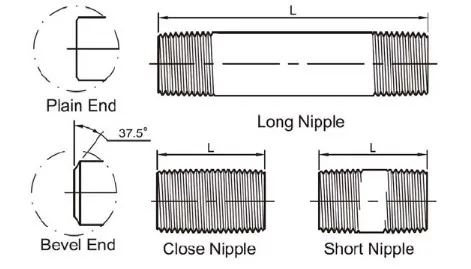

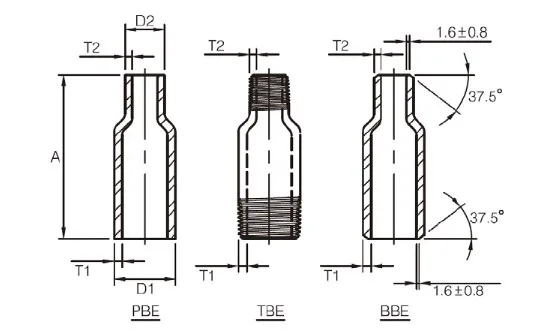

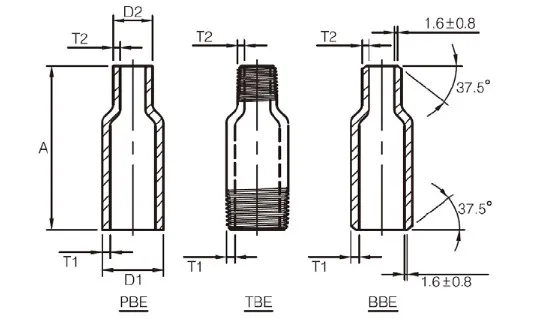

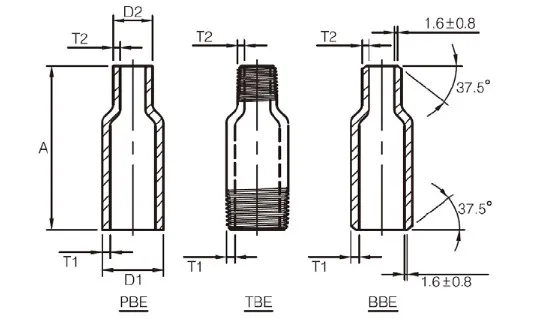

ASTM A733-2016 Threaded Pipe Nipple Bushing Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

L |

Plain End Weight (kg/m) |

| Close Nipple |

Short Nipple |

Long Nipple |

Sch40/ST D |

Sch80/XS |

Sch160 |

XXS |

| 1/8” |

3/4” |

1-1/2” |

2”~12” |

0.37 |

0.47 |

- |

- |

| 1/4” |

7/8” |

1-1/2” |

2”~12” |

0.63 |

0.8 |

- |

- |

| 3/8” |

1” |

1-1/2” |

2”~12” |

0.84 |

1.1 |

- |

- |

| 1/2” |

1-1/8” |

1-1/2” |

2”~12” |

1.27 |

1.62 |

1.95 |

2.55 |

| 3/4” |

1-3/8” |

2” |

2-1/2”~12” |

1.69 |

2.2 |

2.9 |

3.64 |

| 1” |

1-1/2” |

2” |

2-1/2”~12” |

2.5 |

3.24 |

4.24 |

5.45 |

| 1-1/4” |

1-5/8” |

2-1/2” |

3”~12” |

3.39 |

4.47 |

5.61 |

7.77 |

| 1-1/2” |

1-3/4” |

2-1/2” |

3”~12” |

4.05 |

5.41 |

7.25 |

9.55 |

| 2” |

2” |

2-1/2” |

3”~12” |

5.44 |

7.48 |

11.11 |

13.44 |

| 2-1/2” |

2-1/2” |

3” |

3-1/2”~12” |

8.63 |

11.41 |

14.92 |

20.39 |

| 3” |

2-5/8” |

3” |

3-1/2”~12” |

11.29 |

15.27 |

21.35 |

27.68 |

| 3-1/2” |

2-3/4” |

4” |

4-1/2”~12” |

13.57 |

18.64 |

- |

- |

| 4” |

2-7/8” |

4” |

4-1/2”~12” |

16.08 |

22.32 |

33.54 |

41.03 |

| 5” |

3” |

4-1/2” |

5”~12” |

21.77 |

30.97 |

49.12 |

57.43 |

| 6” |

3-1/8” |

4-1/2” |

5”~12” |

28.26 |

42.56 |

67.57 |

79.22 |

Weld bevel in accordance with ASME B16.25.

ASME B16.11-2011 Threaded Union (3000Lb) Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

Pipe End (Min) A |

Wall (Min) C |

Water Way Bore D(1) |

Male Flange (Min) F |

Nut (Min) G |

Threads Per 25.4mmH |

Bearing (Min) J |

Length Assem. Nom. L |

Clear Assem. Nut N |

| 1/8” |

14.7 |

2.41 |

"8.43

6.43" |

3.18 |

3.18 |

16 |

1.24 |

41.4 |

50.8 |

| 1/4” |

19.0 |

3.02 |

"11.13

9.45" |

3.18 |

3.18 |

16 |

1.24 |

41.4 |

50.8 |

| 3/8” |

22.9 |

3.20 |

"14.27

13.51" |

3.43 |

3.43 |

14 |

1.37 |

46.0 |

55.9 |

| 1/2” |

27.7 |

3.73 |

"17.86

17.07" |

3.68 |

3.68 |

14 |

1.50 |

49.0 |

58.4 |

| 3/4” |

33.5 |

3.91 |

"23.01

21.39" |

4.06 |

4.06 |

11 |

1.68 |

56.9 |

66.0 |

| 1” |

41.4 |

4.55 |

"28.98

27.74" |

4.57 |

4.45 |

11 |

1.85 |

62.0 |

78.7 |

| 1-1/4” |

50.5 |

4.85 |

"37.69

35.36" |

5.33 |

5.21 |

11 |

2.13 |

71.1 |

94.0 |

| 1-1/2” |

57.2 |

5.08 |

"43.54

41.20" |

5.84 |

5.59 |

10 |

2.31 |

76.5 |

111.8 |

| 2” |

70.1 |

5.54 |

"55.58

52.12" |

6.60 |

6.35 |

10 |

2.69 |

86.1 |

132.1 |

| 2-1/2” |

85.3 |

7.01 |

"66.27

64.31" |

7.49 |

7.11 |

8 |

3.07 |

102.4 |

149.9 |

| 3” |

102.4 |

7.62 |

"88.25

77.27" |

8.26 |

8.00 |

8 |

3.53 |

109.0 |

175.3 |

Dimensions in accordance with MSS SP-83-2014.

ASME B16.11-2011 Threaded Union (6000Lb) Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

Pipe End (Min) A |

Wall (Min) C |

Water Way Bore D(1) |

Male Flange (Min) F |

Nut (Min) G |

Threads Per 25.4mmH |

Bearing (Min) J |

Length Assem. Nom. L |

Clear Assem. Nut N |

| 1/8” |

16.5 |

3.15 |

"8.43

3.20" |

3.18 |

3.18 |

16 |

1.24 |

41.4 |

50.8 |

| 1/4” |

21.1 |

3.68 |

"11.13

5.59" |

3.43 |

3.43 |

14 |

1.37 |

46.0 |

55.9 |

| 3/8” |

25.1 |

4.01 |

"14.27

8.36" |

3.68 |

3.68 |

14 |

1.50 |

49.0 |

58.4 |

| 1/2” |

31.0 |

4.78 |

"17.86

11.02" |

4.06 |

4.06 |

11 |

1.68 |

56.9 |

66.0 |

| 3/4” |

37.8 |

5.56 |

"23.01

14.78" |

4.57 |

4.45 |

11 |

1.85 |

62.0 |

78.7 |

| 1” |

46.2 |

6.35 |

"28.98

19.94" |

5.33 |

5.21 |

10 |

2.13 |

71.1 |

94.0 |

| 1-1/4” |

54.9 |

6.35 |

"37.69

28.70" |

5.84 |

5.59 |

10 |

2.31 |

76.5 |

111.8 |

| 1-1/2” |

62.5 |

7.14 |

"43.54

33.22" |

6.60 |

6.35 |

10 |

2.69 |

86.1 |

132.1 |

| 2” |

77.7 |

8.74 |

"55.58 |

| 42.09" |

7.49 |

7.11 |

8 |

3.07 |

102.4 |

149.9 |

| 2-1/2” |

92.2 |

9.53 |

"66.27

53.21" |

8.26 |

8.00 |

8 |

3.53 |

109.0 |

175.3 |

| 3” |

111.3 |

11.13 |

"82.55

65.89" |

10.19 |

10.19 |

8 |

4.06 |

158 (2) |

200.7 |

1. This length 158mm is by our standard and the

length

as per MSS SP-83-2014 is 190.5mm.

2. Dimensions in accordance with MSS SP-83-2014.

ASME B16.11-2011 Threaded Adapter (3000Lb) Weight and Dimension Chart (mm, kg)

| DN |

Nom Pipe Size |

D |

L |

Threaded Size B |

| 8 |

1/4” |

19 |

33 |

1/8” |

| 10 |

3/8” |

22 |

35 |

1/4” |

| 15 |

1/2” |

28 |

42 |

3/8” |

| 20 |

3/4” |

35 |

47 |

1/2” |

| 25 |

1” |

44 |

55 |

3/4” |

| 32 |

1-1/4” |

57 |

63 |

1” |

| 40 |

1-1/2” |

64 |

66 |

1-1/4” |

| 50 |

2” |

76 |

76 |

1-1/2” |

| 65 |

2-1/2” |

92 |

90 |

2” |

| 80 |

3” |

108 |

110 |

2-1/2” |

| 100 |

4” |

140 |

120 |

3” |

ASME B16.11-2011 Threaded 90° Elbow Outlet Weight and Dimension Chart (mm, kg)

| Outlet Pipe |

A |

C |

F |

| DN |

Inch |

3000Lb |

6000Lb |

3000Lb |

6000Lb |

3000Lb |

6000Lb |

| 8 |

1/4” |

40.5 |

40.5 |

35.2 |

34.9 |

22.0 |

26.0 |

| 10 |

3/8” |

40.5 |

40.5 |

35.2 |

34.9 |

25.9 |

33.0 |

| 15 |

1/2” |

40.5 |

47.6 |

35.2 |

34.9 |

31.4 |

38.0 |

| 20 |

3/4” |

47.6 |

55.6 |

43.6 |

43.6 |

37.1 |

44.0 |

| 25 |

1” |

55.6 |

60.3 |

54.0 |

54.0 |

45.5 |

57.0 |

| 32 |

1-1/4” |

60.3 |

66.7 |

67.5 |

67.5 |

57.0 |

64.0 |

| 40 |

1-1/2” |

66.7 |

85.7 |

76.2 |

76.2 |

64.0 |

76.0 |

| 50 |

2” |

81.0 |

- |

104.8 |

- |

76.0 |

- |

| 65 |

2-1/2” |

82.6 |

- |

106.4 |

- |

92.0 |

- |

| 80 |

3” |

96.8 |

- |

125.4 |

- |

109.2 |

- |

| 100 |

4” |

114.3 |

- |

163.5 |

- |

140.0 |

- |

ASME B16.11-2011 Socket Weld 90° Elbow Weight and Dimension Chart (mm, kg)

| DN |

Nom Pipe Size |

A |

B |

D |

C (1) |

G(min) |

J(min) |

| 3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

| Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

11.0 |

11.0 |

- |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

2.41 |

3.15 |

- |

9.5 |

| 8 |

1/4” |

11.0 |

13.5 |

- |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

3.02 |

3.68 |

- |

9.5 |

| 10 |

3/8” |

13.5 |

15.5 |

- |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

3.20 |

4.01 |

- |

9.5 |

| 15 |

1/2” |

15.5 |

19.0 |

25.5 |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

3.73 |

4.78 |

7.47 |

9.5 |

| 20 |

3/4” |

19.0 |

22.5 |

28.5 |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

3.91 |

5.56 |

7.82 |

12.5 |

| 25 |

1” |

22.5 |

27.0 |

32.0 |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

4.55 |

6.35 |

9.09 |

12.5 |

| 32 |

1-1/4” |

27.0 |

32.0 |

35.0 |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

4.85 |

6.35 |

9.70 |

12.5 |

| 40 |

1-1/2” |

32.0 |

38.0 |

38.0 |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

5.08 |

7.14 |

10.15 |

12.5 |

| 50 |

2” |

38.0 |

41.0 |

54.0 |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

5.54 |

8.74 |

11.07 |

16.0 |

| 65 |

2-1/2” |

41.0 |

- |

- |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

7.01 |

- |

- |

16.0 |

| 80 |

3” |

57.0 |

- |

- |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

7.62 |

- |

- |

16.0 |

| 100 |

4” |

66.5 |

- |

- |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

8.56 |

- |

- |

19.0 |

ASME B16.11-2011 Socket Weld 45° Elbow Weight and Dimension Chart (mm, kg)

| DN |

Nom Pipe Size |

A |

B |

D |

C (1) |

G(min) |

J(min) |

| 3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

| Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

11.0 |

11.0 |

- |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

2.41 |

3.15 |

- |

9.5 |

| 8 |

1/4” |

11.0 |

13.5 |

- |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

3.02 |

3.68 |

- |

9.5 |

| 10 |

3/8” |

13.5 |

15.5 |

- |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

3.20 |

4.01 |

- |

9.5 |

| 15 |

1/2” |

15.5 |

19.0 |

25.5 |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

3.73 |

4.78 |

7.47 |

9.5 |

| 20 |

3/4” |

19.0 |

22.5 |

28.5 |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

3.91 |

5.56 |

7.82 |

12.5 |

| 25 |

1” |

22.5 |

27.0 |

32.0 |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

4.55 |

6.35 |

9.09 |

12.5 |

| 32 |

1-1/4” |

27.0 |

32.0 |

35.0 |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

4.85 |

6.35 |

9.70 |

12.5 |

| 40 |

1-1/2” |

32.0 |

38.0 |

38.0 |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

5.08 |

7.14 |

10.15 |

12.5 |

| 50 |

2” |

38.0 |

41.0 |

54.0 |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

5.54 |

8.74 |

11.07 |

16.0 |

| 65 |

2-1/2” |

41.0 |

- |

- |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

7.01 |

- |

- |

16.0 |

| 80 |

3” |

57.0 |

- |

- |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

7.62 |

- |

- |

16.0 |

| 100 |

4” |

66.5 |

- |

- |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

8.56 |

- |

- |

19.0 |

ASME B16.11-2011 Socket Weld Tee Weight and Dimension Chart (mm, kg)

| DN |

Nom Pipe Size |

A |

B |

D |

C (1) |

G(min) |

J(min) |

| 3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

| Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

11.0 |

11.0 |

- |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

2.41 |

3.15 |

- |

9.5 |

| 8 |

1/4” |

11.0 |

13.5 |

- |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

3.02 |

3.68 |

- |

9.5 |

| 10 |

3/8” |

13.5 |

15.5 |

- |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

3.20 |

4.01 |

- |

9.5 |

| 15 |

1/2” |

15.5 |

19.0 |

25.5 |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

3.73 |

4.78 |

7.47 |

9.5 |

| 20 |

3/4” |

19.0 |

22.5 |

28.5 |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

3.91 |

5.56 |

7.82 |

12.5 |

| 25 |

1” |

22.5 |

27.0 |

32.0 |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

4.55 |

6.35 |

9.09 |

12.5 |

| 32 |

1-1/4” |

27.0 |

32.0 |

35.0 |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

4.85 |

6.35 |

9.70 |

12.5 |

| 40 |

1-1/2” |

32.0 |

38.0 |

38.0 |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

5.08 |

7.14 |

10.15 |

12.5 |

| 50 |

2” |

38.0 |

41.0 |

54.0 |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

5.54 |

8.74 |

11.07 |

16.0 |

| 65 |

2-1/2” |

41.0 |

- |

- |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

7.01 |

- |

- |

16.0 |

| 80 |

3” |

57.0 |

- |

- |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

7.62 |

- |

- |

16.0 |

| 100 |

4” |

66.5 |

- |

- |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

8.56 |

- |

- |

19.0 |

ASME B16.11-2011 Socket Weld 45° Lateral Tee Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

B |

C(1) |

D(1) |

A |

E |

G(1) (Min) |

J(1) (Min) |

| 3M |

3M |

3M |

6M |

3M |

6M |

3M |

6M |

3M |

6M |

| Avg |

Min |

Avg |

Min |

| 15 |

1/2” |

21.8 |

4.67 |

5.97 |

4.09 |

5.18 |

15.8 |

11.8 |

35 |

41 |

9 |

9 |

3.75 |

4.78 |

9.5 |

| 20 |

3/4” |

27.2 |

4.90 |

6.96 |

4.27 |

6.04 |

21.0 |

15.6 |

41 |

51 |

9 |

12 |

3.95 |

5.56 |

12.5 |

| 25 |

1” |

33.9 |

5.69 |

7.92 |

4.98 |

6.93 |

26.7 |

20.7 |

51 |

59 |

12 |

17 |

4.55 |

6.35 |

12.5 |

| 32 |

1-1/4” |

42.7 |

6.07 |

7.92 |

5.28 |

6.93 |

35.1 |

29.5 |

59 |

68 |

17 |

21 |

4.85 |

6.35 |

12.5 |

| 40 |

1-1/2” |

48.8 |

6.35 |

8.92 |

5.54 |

7.80 |

40.9 |

34.0 |

68 |

95 |

21 |

24 |

5.10 |

7.14 |

12.5 |

| 50 |

2” |

61.2 |

6.93 |

10.92 |

6.04 |

9.50 |

52.5 |

42.9 |

95 |

106 |

24 |

31 |

5.55 |

8.74 |

16.0 |

| 65 |

2-1/2” |

73.9 |

8.76 |

- |

7.67 |

- |

62.7 |

- |

118 |

- |

38 |

- |

7.05 |

- |

16.0 |

ASME B16.11-2011 Socket Weld Cross Weight and Dimension Chart (mm, kg)

| DN |

Nom Pipe Size |

A |

B |

D |

C (1) |

G(min) |

J(min) |

| 3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

3M |

6M |

9M |

| Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

11.0 |

11.0 |

- |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

2.41 |

3.15 |

- |

9.5 |

| 8 |

1/4” |

11.0 |

13.5 |

- |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

3.02 |

3.68 |

- |

9.5 |

| 10 |

3/8” |

13.5 |

15.5 |

- |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

3.20 |

4.01 |

- |

9.5 |

| 15 |

1/2” |

15.5 |

19.0 |

25.5 |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

3.73 |

4.78 |

7.47 |

9.5 |

| 20 |

3/4” |

19.0 |

22.5 |

28.5 |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

3.91 |

5.56 |

7.82 |

12.5 |

| 25 |

1” |

22.5 |

27.0 |

32.0 |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

4.55 |

6.35 |

9.09 |

12.5 |

| 32 |

1-1/4” |

27.0 |

32.0 |

35.0 |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

4.85 |

6.35 |

9.70 |

12.5 |

| 40 |

1-1/2” |

32.0 |

38.0 |

38.0 |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

5.08 |

7.14 |

10.15 |

12.5 |

| 50 |

2” |

38.0 |

41.0 |

54.0 |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

5.54 |

8.74 |

11.07 |

16.0 |

| 65 |

2-1/2” |

41.0 |

- |

- |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

7.01 |

- |

- |

16.0 |

| 80 |

3” |

57.0 |

- |

- |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

7.62 |

- |

- |

16.0 |

| 100 |

4” |

66.5 |

- |

- |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

8.56 |

- |

- |

19.0 |

ASME B16.11-2011 Socket Weld Full Coupling Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Socket Bore Dia. B |

Bore Dia. Of Fitting D |

Socket Wall Thickness C1 |

Laying Length E |

Depth of Socket (Min) J |

| 3M |

6M |

9M |

| 3M |

6M |

9M |

Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

6.5 |

9.5 |

| 8 |

1/4” |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

6.5 |

9.5 |

| 10 |

3/8” |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

6.5 |

9.5 |

| 15 |

1/2” |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

9.5 |

9.5 |

| 20 |

3/4” |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

9.5 |

12.5 |

| 25 |

1” |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

12.5 |

12.5 |

| 32 |

1-1/4” |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

12.5 |

12.5 |

| 40 |

1-1/2” |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

12.5 |

12.5 |

| 50 |

2” |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

19.0 |

16.0 |

| 65 |

2-1/2” |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

19.0 |

16.0 |

| 80 |

3” |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

19.0 |

16.0 |

| 100 |

4” |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

19.0 |

19.0 |

ASME B16.11-2011 Socket Weld Half Coupling Weight and Dimension Chart (mm, kg)

| DN |

Nom. Pipe Size |

Socket Bore Dia. B |

Bore Dia. Of Fitting D |

Socket Wall Thickness C1 |

Laying Length E |

Depth of Socket (Min) J |

| 3M |

6M |

9M |

| 3M |

6M |

9M |

Avg |

Min |

Avg |

Min |

Avg |

Min |

| 6 |

1/8” |

10.8 |

6.9 |

4.0 |

- |

3.18 |

3.18 |

3.96 |

3.43 |

- |

- |

16.0 |

9.5 |

| 8 |

1/4” |

14.2 |

9.3 |

6.4 |

- |

3.78 |

3.30 |

4.60 |

4.01 |

- |

- |

16.0 |

9.5 |

| 10 |

3/8” |

17.6 |

12.6 |

9.2 |

- |

4.01 |

3.50 |

5.03 |

4.37 |

- |

- |

17.5 |

9.5 |

| 15 |

1/2” |

21.8 |

15.8 |

11.8 |

6.4 |

4.67 |

4.09 |

5.97 |

5.18 |

9.35 |

8.18 |

22.5 |

9.5 |

| 20 |

3/4” |

27.2 |

21.0 |

15.6 |

11.1 |

4.90 |

4.27 |

6.96 |

6.04 |

9.78 |

8.56 |

24.0 |

12.5 |

| 25 |

1” |

33.9 |

26.7 |

20.7 |

15.2 |

5.69 |

4.98 |

7.92 |

6.93 |

11.38 |

9.96 |

28.5 |

12.5 |

| 32 |

1-1/4” |

42.7 |

35.1 |

29.5 |

22.8 |

6.07 |

5.28 |

7.92 |

6.93 |

12.14 |

10.62 |

30.0 |

12.5 |

| 40 |

1-1/2” |

48.8 |

40.9 |

34.0 |

28.0 |

6.35 |

5.54 |

8.92 |

7.80 |

12.70 |

11.12 |

32.0 |

12.5 |

| 50 |

2” |

61.2 |

52.5 |

42.9 |

38.2 |

6.93 |

6.04 |

10.92 |

9.50 |

13.84 |

12.12 |

41.0 |

16.0 |

| 65 |

2-1/2” |

73.9 |

62.7 |

- |

- |

8.76 |

7.67 |

- |

- |

- |

- |

43.0 |

16.0 |

| 80 |

3” |

89.8 |

78.0 |

- |

- |

9.52 |

8.30 |

- |

- |

- |

- |

44.5 |

16.0 |

| 100 |

4” |

115.2 |

102.3 |

- |

- |

10.69 |

9.35 |

- |

- |

- |

- |

48.0 |

19.0 |

ASME B16.11-2011 Socket Weld Reducing Coupling Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

H |

B1 |

B2 |

D |

J |

L |

| 3M |

6M |

3M |

6M |

3M |

6M |

3M |

6M |

| 1/4”x1/8” |

22.2 |

23.8 |

14.3 |

10.9 |

6.9 |

4.0 |

10.5 |

10.5 |

27.5 |

27.5 |

| 3/8”x1/8” |

26.1 |

28.1 |

17.7 |

10.9 |

6.9 |

4.0 |

10.5 |

10.5 |

28.5 |

28.5 |

| 3/8”x1/4” |

26.1 |

28.1 |

17.7 |

14.3 |

9.3 |

6.4 |

10.5 |

10.5 |

28.5 |

28.5 |

| 1/2”x1/8” |

31.6 |

34.2 |

21.9 |

10.9 |

6.9 |

4.0 |

12.5 |

12.5 |

34.5 |

34.5 |

| 1/2”x1/4” |

31.6 |

34.2 |

21.9 |

13.3 |

9.3 |

6.4 |

12.5 |

12.5 |

34.5 |

34.5 |

| 1/2”x3/8” |

31.6 |

34.2 |

21.9 |

17.7 |

12.6 |

9.2 |

12.5 |

12.5 |

34.5 |

34.5 |

| 3/4”x1/8” |

37.4 |

41.6 |

27.3 |

10.9 |

6.9 |

4.0 |

14.0 |

14.0 |

37.5 |

37.5 |

| 3/4”x1/4” |

37.4 |

41.6 |

27.3 |

14.3 |

9.3 |

6.4 |

14.0 |

14.0 |

37.5 |

37.5 |

| 3/4”x3/8” |

37.4 |

41.6 |

27.3 |

17.7 |

12.6 |

9.2 |

14.0 |

14.0 |

37.5 |

37.5 |

| 3/4”x1/2” |

37.4 |

41.6 |

27.3 |

21.9 |

15.8 |

11.8 |

14.0 |

14.0 |

37.5 |

37.5 |

| 1”x1/8” |

45.7 |

50.2 |

34.0 |

10.9 |

6.9 |

4.0 |

15.0 |

15.0 |

43.0 |

43.0 |

| 1x1/4” |

45.7 |

50.2 |

34.0 |

14.3 |

9.3 |

6.4 |

15.0 |

15.0 |

43.0 |

43.0 |

| 1”x3/8” |

45.7 |

50.2 |

34.0 |

17.7 |

12.6 |

9.2 |

15.0 |

15.0 |

43.0 |

43.0 |

| 1”x1/2” |

45.7 |

50.2 |

34.0 |

21.9 |

15.8 |

11.8 |

15.0 |

15.0 |

43.0 |

43.0 |

| 1”x3/4” |

45.7 |

50.2 |

34.0 |

27.3 |

21.0 |

15.6 |

15.0 |

15.0 |

43.0 |

43.0 |

| 1-1/4”x1/8” |

55.3 |

59.0 |

42.8 |

10.9 |

6.9 |

4.0 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/4”x1/4” |

55.3 |

59.0 |

42.8 |

14.3 |

9.3 |

6.4 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/4”x3/8” |

55.3 |

59.0 |

42.8 |

17.7 |

12.6 |

9.2 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/4”x1/2” |

55.3 |

59.0 |

42.8 |

21.9 |

15.8 |

11.8 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/4”x3/4” |

55.3 |

59.0 |

42.8 |

27.3 |

21.0 |

15.6 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/4”x1” |

55.3 |

59.0 |

42.8 |

34.0 |

26.7 |

20.7 |

17.0 |

17.0 |

47.0 |

47.0 |

| 1-1/2”x1/8” |

62.5 |

67.1 |

48.9 |

10.9 |

6.9 |

4.0 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x1/4” |

62.5 |

67.1 |

48.9 |

14.3 |

9.3 |

6.4 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x3/8” |

62.5 |

67.1 |

48.9 |

17.7 |

12.6 |

9.2 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x1/2” |

62.5 |

67.1 |

48.9 |

21.9 |

15.8 |

11.8 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x3/4” |

62.5 |

67.1 |

48.9 |

27.3 |

21.0 |

15.6 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x1” |

62.5 |

67.1 |

48.9 |

34.0 |

26.7 |

20.7 |

17.5 |

17.5 |

48.0 |

48.0 |

| 1-1/2”x1-1/4” |

62.5 |

67.1 |

48.9 |

42.8 |

35.1 |

29.5 |

17.5 |

17.5 |

48.0 |

48.0 |

| 2”x1/8” |

75.6 |

83.6 |

61.4 |

10.9 |

6.9 |

4.0 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x1/4” |

75.6 |

83.6 |

61.4 |

14.3 |

9.3 |

6.4 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x3/8” |

75.6 |

83.6 |

61.4 |

17.7 |

12.6 |

9.2 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x1/2” |

75.6 |

83.6 |

61.4 |

21.9 |

15.8 |

11.8 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x3/4” |

75.6 |

83.6 |

61.4 |

27.3 |

21.0 |

15.6 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x1” |

75.6 |

83.6 |

61.4 |

34.0 |

26.7 |

20.7 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2”x1-1/4” |

75.6 |

83.6 |

61.4 |

42.8 |

35.1 |

29.5 |

22.0 |

22.0 |

63.0 |

63.0 |

ASME B16.11-2011 Socket Weld Reducing Coupling Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

H |

B1 |

B2 |

D |

J |

L |

| 3M |

6M |

3M |

6M |

3M |

6M |

3M |

6M |

2”x1-1/2” |

75.6 |

83.6 |

61.4 |

48.9 |

40.9 |

34.0 |

22.0 |

22.0 |

63.0 |

63.0 |

| 2-1/2”x1/8” |

92.0 |

108.5 |

74.1 |

10.9 |

6.9 |

4.0 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x1/4” |

92.0 |

108.5 |

74.1 |

14.3 |

9.3 |

6.4 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x3/8” |

92.0 |

108.5 |

74.1 |

17.7 |

12.6 |

9.2 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x1/2” |

92.0 |

108.5 |

74.1 |

21.9 |

15.8 |

11.8 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x3/4” |

92.0 |

108.5 |

74.1 |

27.3 |

21.0 |

15.6 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x1” |

92.0 |

108.5 |

74.1 |

34.0 |

26.7 |

20.7 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x1-1/4” |

92.0 |

108.5 |

74.1 |

42.8 |

35.1 |

29.5 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x1-1/2” |

92.0 |

108.5 |

74.1 |

48.9 |

40.9 |

34.0 |

22.0 |

22.4 |

63.0 |

63.5 |

| 2-1/2”x2” |

92.0 |

108.5 |

74.1 |

61.4 |

52.5 |

42.9 |

22.0 |

22.4 |

63.0 |

63.5 |

| 3”x1/8” |

109.4 |

127.6 |

90.0 |

10.9 |

6.9 |

4.0 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x1/4” |

109.4 |

127.6 |

90.0 |

14.3 |

9.3 |

6.4 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x3/8” |

109.4 |

127.6 |

90.0 |

17.7 |

12.6 |

9.2 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x1/2” |

109.4 |

127.6 |

90.0 |

21.9 |

15.8 |

11.8 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x3/4” |

109.4 |

127.6 |

90.0 |

27.3 |

21.0 |

15.6 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x1” |

109.4 |

127.6 |

90.0 |

34.0 |

26.7 |

20.7 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x1-1/4” |

109.4 |

127.6 |

90.0 |

42.8 |

35.1 |

29.5 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x1-1/2” |

109.4 |

127.6 |

90.0 |

48.9 |

40.9 |

34.0 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x2” |

109.4 |

127.6 |

90.0 |

61.4 |

52.5 |

42.9 |

22.0 |

25.5 |

63.0 |

70.0 |

| 3”x2-1/2” |

109.4 |

127.6 |

90.0 |

74.1 |

62.7 |

53.8 |

22.0 |

25.5 |

63.0 |

70.0 |

| 4”x1/8” |

137.1 |

159.0 |

115.4 |

10.9 |

6.9 |

4.0 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x1/4” |

137.1 |

159.0 |

115.4 |

14.3 |

9.3 |

6.4 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x3/8” |

137.1 |

159.0 |

115.4 |

17.7 |

12.6 |

9.2 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x1/2” |

137.1 |

159.0 |

115.4 |

21.9 |

15.8 |

11.8 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x3/4” |

137.1 |

159.0 |

115.4 |

27.3 |

21.0 |

15.6 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x1” |

137.1 |

159.0 |

115.4 |

34.0 |

26.7 |

20.7 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x1-1/4” |

137.1 |

159.0 |

115.4 |

42.8 |

35.1 |

29.5 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x1-1/2” |

137.1 |

159.0 |

115.4 |

48.9 |

40.9 |

34.0 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x2” |

137.1 |

159.0 |

115.4 |

61.4 |

52.5 |

42.9 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x2-1/2” |

137.1 |

159.0 |

115.4 |

74.1 |

62.7 |

53.8 |

22.0 |

28.4 |

63.0 |

76.2 |

| 4”x3” |

137.1 |

159.0 |

115.4 |

90.0 |

78.0 |

66.5 |

22.0 |

28.4 |

63.0 |

76.2 |

ASME B16.11-2011 Socket Weld Eccentric Reducer Coupling Weight and Dimension Chart (mm, kg)

| Nom. Pipe Size |

B1 |

B2 |

D |

C(Min) |

H |

J |

L |

| 1/4”x1/8” |

14.3 |

10.9 |

6.9 |

3.80 |

22.2 |

10.5 |

27.5 |

| 3/8”x1/8” |

17.7 |

10.9 |

6.9 |

4.05 |

26.1 |

10.5 |

28.5 |

| 3/8”x1/4” |

17.7 |

14.3 |

9.3 |

4.05 |

25.1 |

10.5 |

28.5 |

| 1/2”x1/4” |

21.9 |

14.3 |

9.3 |

4.70 |

31.6 |

12.5 |

34.5 |

| 1/2”x3/8” |

21.9 |

17.7 |

12.6 |

4.70 |

31.6 |

12.5 |

34.5 |

| 3/4”x3/8” |

27.3 |

17.7 |

12.6 |

4.90 |

37.4 |

14.0 |

37.5 |

| 3/4”x1/2” |

27.3 |

21.9 |

15.8 |

4.90 |

37.4 |

14.0 |

37.5 |

| 1”x3/8” |

34.0 |

17.7 |

12.6 |

5.70 |

45.7 |

15.0 |

43.0 |

| 1”x1/2” |

34.0 |

21.9 |

15.8 |

5.70 |

45.7 |

15.0 |

43.0 |

| 1”x3/4” |

34.0 |

27.3 |

21.0 |

5.70 |

45.7 |

15.0 |

43.0 |

| 1-1/4”x1/2” |

42.8 |

21.9 |

15.8 |

6.10 |

55.3 |

17.0 |

47.0 |

| 1-1/4”x3/4” |

42.8 |

27.3 |

21.0 |

6.10 |

55.3 |

17.0 |

47.0 |

| 1-1/4”x1” |

42.8 |

34.0 |

26.7 |

6.10 |

55.3 |

17.0 |

47.0 |

| 1-1/2”x1/2” |

48.9 |

21.9 |

15.8 |

6.40 |

62.5 |

17.5 |

48.0 |

| 1-1/2”x3/4” |