ASME B16.22 Copper Socket Weld Fittings, Dimensions Chart in mm, kg, PDF online

Socket weld fittings are important components in piping systems used to connect pipes or tubes to other pipes, valves, or equipment safely and with minimal leakage. These fittings have a socket or recessed area into which the pipe end is inserted and then joined by welding. Socket weld fittings are commonly used in high-pressure and high-temperature applications. Socket weld fittings are available in various sizes, normally ranging from 1/8 inch to 4 inches or larger. Socket weld fittings are manufactured for high-pressure applications. They are normally rated based on pressure classes, such as 3000#, 6000#, and 9000#. The pressure class indicates the fittings' maximum working pressure at various temperatures. Copper Socket Weld Weight, Dimensions Chart is given below. Socket weld fittings are joined to pipes or tubes using a socket weld process. This involves inserting the pipe end into the socket and welding the joint. Proper welding methods and processes are important to ensure a strong, leak-resistant connection.

Features of Copper Socket Weld Fittings:

- Copper socket weld fittings are usually made from copper alloys, with the most common being copper-nickel alloys such as Cu-Ni 90/10 (90% copper and 10% nickel) and Cu-Ni 70/30 (70% copper and 30% nickel).

- Copper-nickel alloys, which are commonly used for socket weld fittings, show exceptional corrosion resistance, especially in saltwater and other corrosive environments. They resist both general corrosion and stress corrosion cracking.

- Copper socket weld fittings can withstand high-temperature applications, making them fit for various industrial processes.

- Offer leakage-proof and strong connection to operate effectively in the piping systems.

- Copper socket weld fittings generally require minimum maintenance, mainly due to their corrosion resistance.

- Easy to install.

- Marine and Shipbuilding: Copper-nickel socket weld fittings have common usage in marine and shipbuilding applications due to their excellent resistance to seawater corrosion.

- Petrochemical Industry: These fittings are used in the petrochemical industry for oil and gas processing equipment, where corrosion resistance is very important.

- Heat Exchangers: Copper socket weld fittings are used in heat exchangers, where the ability to withstand high temperatures and corrosive fluids is primary.

- HVAC Systems: They can be used in HVAC (Heating, Ventilation, and Air Conditioning) systems for refrigerant and coolant lines.

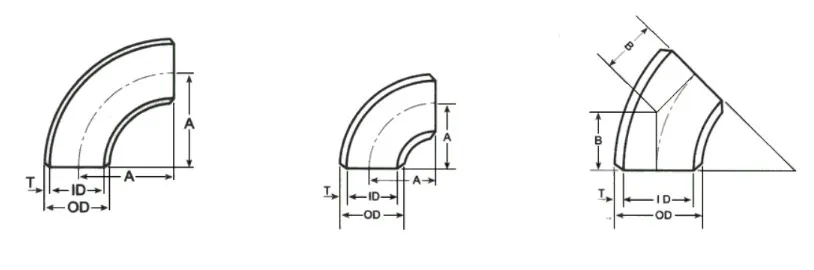

- Elbows

- Tees

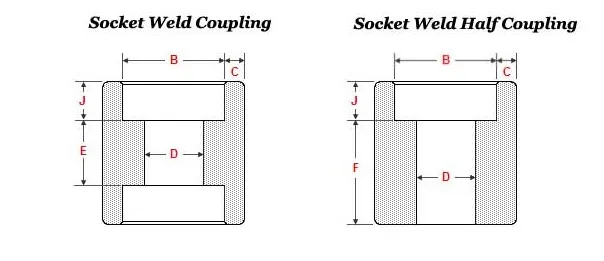

- Coupling

- Cap

- Union

Specifications of Copper socket weld Fittings

The dimensional standard of the Socket Weld fittings we supply are in accordance with the American National Standards Institute (ANSI): ANSI B16.9, MSS SP43 and MSS SP75. All the specifications of Socket Weld fittings are mentioned in the Dimensions Chart below.

Types of Copper socket weld fitting:

The types of Copper socket weld fitting are:

And many more...

ASME B16.22 90°/45° Long and Short Radius Elbow Weight and Dimension Chart (mm, kg)

Copper Socket weld Fittings Specifications

| Specifications | ASTM B62 & ASME B62 |

|---|---|

| Size | 1/8” NB to 4” NB (Socketweld & Screwed-Threaded) |

| Standards |

ASME 16.15, MSS SP-79, 83, 95, 97, BS 3799 |

| Class | 2000 LBS, 3000 LBS, 6000 LBS, 9000 LBS |

| Type | Socketweld Fittings |

Copper Forged Socket weld Fittings Chemical Composition

| Standard | Copper NO. | Chemical Composition | Mechanical Properties | ||||

|---|---|---|---|---|---|---|---|

| CU% | P% | Temper | Tensile strength (Mpa) | Elongation (%) | Average Grain Size (mm) | ||

| ASTM B280/68 |

C12200 | >99.9 | 0.015 to 0.040 | >60 | >205 | >40 | >0.040 |

| >50 | >245 | ||||||

Class 3000 Full Coupling Dimensions

| NPS |

Socket Bore |

Depth Socket |

Bore diameter |

Socket wall thickness |

Laying lengths | |

|---|---|---|---|---|---|---|

| B | J | D | C |

Coupling E |

||

| 1/2 |

21.95 21.70 |

10 |

16.6 15 |

4.65 4.10 |

9.5 | |

| 3/4 |

27.30 27.05 |

13 |

21.7 20.2 |

4.90 4.25 |

9.5 | |

| 1 |

34.05 33.80 |

13 |

27.4 25.9 |

5.70 5.00 |

13 | |

| 1¼ |

42.80 42.55 |

13 |

35.8 34.3 |

6.05 5.30 |

13 | |

| 1½ |

48.90 48.65 |

13 |

41.7 40.1 |

6.35 5.55 |

13 | |

| 2 |

61.35 61.10 |

16 |

53.5 51.7 |

6.95 6.05 |

19 | |

| 2½ |

74.20 73.80 |

16 |

64.2 61.2 |

8.75 7.65 |

19 | |

| 3 |

90.15 89.80 |

16 |

79.5 46.4 |

9.50 8.30 |

19 | |

| 4 |

115.80 115.45 |

19 |

103.8 100.7 |

10.70 9.35 |

19 | |

6000# Socket Weld Full Coupling Dimensions

| NPS |

Socket Bore |

Depth Socket |

Bore diameter |

Socket wall thickness |

Laying lengths | |

|---|---|---|---|---|---|---|

| B | J | D | C |

Coupling E |

||

| 1/2 |

21.95 21.70 |

10 |

12.5 11 |

5.95 5.20 |

9.5 | |

| 3/4 |

27.30 27.05 |

13 |

16.3 14.8 |

6.95 6.05 |

9.5 | |

| 1 |

34.05 33.80 |

13 |

21.5 19.9 |

7.90 6.95 |

13 | |

| 1¼ |

42.80 42.55 |

13 |

30.2 28.7 |

7.90 6.95 |

13 | |

| 1½ |

48.90 48.65 |

13 |

34.7 33.2 |

8.90 7.80 |

13 | |

| 2 |

61.35 61.10 |

16 |

43.6 42.1 |

10.90 9.50 |

19 | |