Steel Alloys Socket Weld Fittings Mechanical, Weight, Dimension, Size and Physical Properties Chart Pdf, Table

Steel alloys socket welding fittings play a crucial role in many piping systems as they facilitate a robust and effective connection of pipes. During their welding on the pipes,such joints, which are strong and leak-proof, are made forever. Socket welding fittings could be manufactured from a variety of different materials including carbon steel, stainless steel and nickel alloys. The high reliability imparts these machines for use at different levels in various applications such as high-pressure industrial systems or corrosive environments. Through our website, you will obtain information concerning different Type of steel alloys socket weld fittings, such as mechanical properties, weight, dimension, size, and physical properties. This information is very crucial for the engineers, designers and other professionals who are involved in working with these important components. It makes appropriate choice according to the specific requirements for the project and also ensures safety and reliability in the operation.

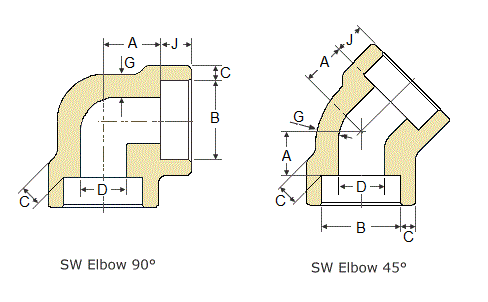

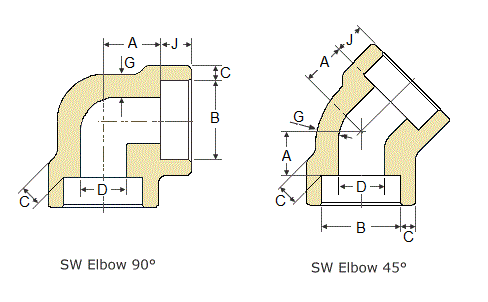

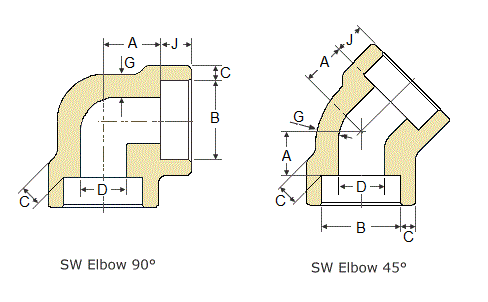

Socket Weld Elbow Dimensions - Class 3000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | 90° Elbow | 45° Elbow | 90° Elbow | 45° Elbow |

| 1/8 | 6 | 10.8 | 11.2 | 6.1 | 7.6 | 3.18 | 3.18 | 2.41 | 9.5 | 11.0 | 8.0 | 0.113 | 0.100 |

| 1/4 | 8 | 14.2 | 14.6 | 8.5 | 10.0 | 3.78 | 3.30 | 3.02 | 9.5 | 11.0 | 8.0 | 0.095 | 0.086 |

| 3/8 | 10 | 17.6 | 18.0 | 11.8 | 13.3 | 4.01 | 3.50 | 3.20 | 9.5 | 13.5 | 8.0 | 0.118 | 0.100 |

| 1/2 | 15 | 21.8 | 22.2 | 15.0 | 16.6 | 4.67 | 4.09 | 3.73 | 9.5 | 15.5 | 11.0 | 0.204 | 0.191 |

| 3/4 | 20 | 27.2 | 27.6 | 20.2 | 21.7 | 4.90 | 4.27 | 3.91 | 12.5 | 19.0 | 13.0 | 0.340 | 0.318 |

| 1 | 25 | 33.9 | 34.3 | 25.9 | 27.4 | 5.69 | 4.98 | 4.55 | 12.5 | 22.5 | 14.0 | 0.476 | 0.431 |

| 1-1/4 | 32 | 42.7 | 43.1 | 34.3 | 35.8 | 6.07 | 5.28 | 4.85 | 12.5 | 27.0 | 17.5 | 0.689 | 0.630 |

| 1-1/2 | 40 | 48.8 | 49.2 | 40.1 | 41.6 | 6.35 | 5.54 | 5.08 | 12.5 | 32.0 | 20.5 | 0.943 | 0.762 |

| 2 | 50 | 61.2 | 61.7 | 51.7 | 53.3 | 6.93 | 6.04 | 5.54 | 16.0 | 38.0 | 25.5 | 1.529 | 1.343 |

| 2-1/2 | 65 | 73.9 | 74.4 | 61.2 | 64.2 | 8.76 | 7.67 | 7.01 | 16.0 | 41.0 | 28.5 | 3.025 | 3.520 |

| 3 | 80 | 89.8 | 90.3 | 76.4 | 79.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | 5.026 | 3.878 |

| 4 | 100 | 115.2 | 115.7 | 100.7 | 103.8 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | 10.247 | 10.913 |

Socket Weld Elbow Dimensions - Class 6000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | 90° Elbow | 45° Elbow | 90° Elbow | 45° Elbow |

| 1/8 | 6 | 10.8 | 11.2 | 3.2 | 4.8 | 3.96 | 3.43 | 3.15 | 9.5 | 11.0 | 8.0 | 0.000 | 0.000 |

| 1/4 | 8 | 14.2 | 14.6 | 5.6 | 7.1 | 4.60 | 4.01 | 3.68 | 9.5 | 13.5 | 8.0 | 0.118 | 0.100 |

| 3/8 | 10 | 17.6 | 18.0 | 8.4 | 9.9 | 5.03 | 4.37 | 4.01 | 9.5 | 15.5 | 11.0 | 0.268 | 0.218 |

| 1/2 | 15 | 21.8 | 22.2 | 11.0 | 12.5 | 5.97 | 5.18 | 4.78 | 9.5 | 19.0 | 12.5 | 0.440 | 0.404 |

| 3/4 | 20 | 27.2 | 27.6 | 14.8 | 16.3 | 6.96 | 6.04 | 5.56 | 12.5 | 22.5 | 14.0 | 0.644 | 0.572 |

| 1 | 25 | 33.9 | 34.3 | 19.9 | 21.5 | 7.92 | 6.93 | 6.35 | 12.5 | 27.0 | 17.5 | 1.057 | 0.907 |

| 1-1/4 | 32 | 42.7 | 43.1 | 28.7 | 30.2 | 7.92 | 6.93 | 6.35 | 12.5 | 32.0 | 20.5 | 1.343 | 1.039 |

| 1-1/2 | 40 | 48.8 | 49.2 | 33.2 | 34.7 | 8.92 | 7.80 | 7.14 | 12.5 | 38.0 | 25.5 | 2.590 | 2.037 |

| 2 | 50 | 61.2 | 61.7 | 42.1 | 43.6 | 10.92 | 9.50 | 8.74 | 16.0 | 41.0 | 28.5 | 2.912 | 2.527 |

Socket Weld Elbow Dimensions - Class 9000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | 90° Elbow | 45° Elbow | 90° Elbow | 45° Elbow |

| 1/2 | 15 | 21.8 | 22.2 | 5.6 | 7.2 | 9.35 | 8.18 | 7.47 | 9.5 | 25.5 | 15.5 | 0.771 | 0.594 |

| 3/4 | 20 | 27.2 | 27.6 | 10.3 | 11.8 | 9.78 | 8.56 | 7.82 | 12.5 | 28.5 | 19.0 | 1.266 | 1.075 |

| 1 | 25 | 33.9 | 34.3 | 14.4 | 16.0 | 11.38 | 9.96 | 9.09 | 12.5 | 32.0 | 20.5 | 1.728 | 1.320 |

| 1-1/4 | 32 | 42.7 | 43.1 | 22.0 | 23.5 | 12.14 | 10.62 | 9.70 | 12.5 | 35.0 | 22.5 | 2.590 | 1.955 |

| 1-1/2 | 40 | 48.8 | 49.2 | 27.2 | 28.7 | 12.70 | 11.12 | 10.15 | 12.5 | 38.0 | 25.5 | 3.697 | 3.125 |

| 2 | 50 | 61.2 | 61.7 | 37.4 | 38.9 | 13.84 | 12.12 | 11.07 | 16.0 | 54.0 | 28.5 | 5.107 | 4.917 |

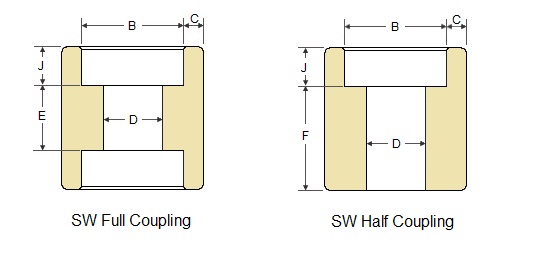

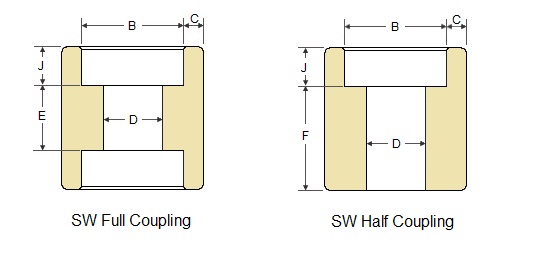

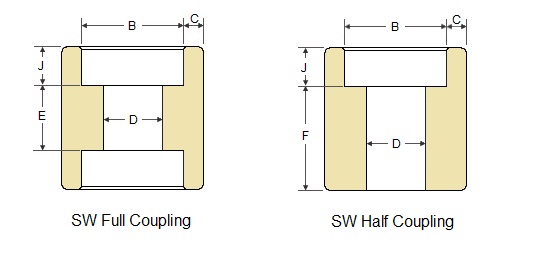

Socket Weld Coupling Dimensions - Class 3000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Socket Depth (J) | Laying Length | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Full Coupling (E) | Half Coupling (F) | Full Coupling | Half Coupling |

| 1/8 | 6 | 10.8 | 11.2 | 6.1 | 7.6 | 3.18 | 3.18 | 9.5 | 6.5 | 16.0 | 0.041 | 0.045 |

| 1/4 | 8 | 14.2 | 14.6 | 8.5 | 10.0 | 3.78 | 3.30 | 9.5 | 6.5 | 16.0 | 0.054 | 0.059 |

| 3/8 | 10 | 17.6 | 18.0 | 11.8 | 13.3 | 4.01 | 3.50 | 9.5 | 6.5 | 17.5 | 0.073 | 0.082 |

| 1/2 | 15 | 21.8 | 22.2 | 15.0 | 16.6 | 4.67 | 4.09 | 9.5 | 9.5 | 22.5 | 0.109 | 0.145 |

| 3/4 | 20 | 27.2 | 27.6 | 20.2 | 21.7 | 4.90 | 4.27 | 12.5 | 9.5 | 24.0 | 0.177 | 0.209 |

| 1 | 25 | 33.9 | 34.3 | 25.9 | 27.4 | 5.69 | 4.98 | 12.5 | 12.5 | 28.5 | 0.259 | 0.340 |

| 1-1/4 | 32 | 42.7 | 43.1 | 34.3 | 35.8 | 6.07 | 5.28 | 12.5 | 12.5 | 30.0 | 0.408 | 0.562 |

| 1-1/2 | 40 | 48.8 | 49.2 | 40.1 | 41.6 | 6.35 | 5.54 | 12.5 | 12.5 | 32.0 | 0.472 | 0.603 |

| 2 | 50 | 61.2 | 61.7 | 51.7 | 53.3 | 6.93 | 6.04 | 16.0 | 19.0 | 41.0 | 0.812 | 1.080 |

| 2-1/2 | 65 | 73.9 | 74.4 | 61.2 | 64.2 | 8.76 | 7.67 | 16.0 | 19.0 | 43.0 | 1.098 | 1.610 |

| 3 | 80 | 89.8 | 90.3 | 76.4 | 79.4 | 9.52 | 8.30 | 16.0 | 19.0 | 44.5 | 1.842 | 2.830 |

| 4 | 100 | 115.2 | 115.7 | 100.7 | 103.8 | 10.69 | 9.35 | 19.0 | 19.0 | 48.0 | 2.599 | 3.765 |

Socket Weld Coupling Dimensions - Class 6000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Socket Depth (J) | Laying Length | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Full Coupling (E) | Half Coupling (F) | Full Coupling | Half Coupling |

| 1/8 | 6 | 10.8 | 11.2 | 3.2 | 4.8 | 3.96 | 3.43 | 9.5 | 6.5 | 16.0 | 0.000 | 0.000 |

| 1/4 | 8 | 14.2 | 14.6 | 5.6 | 7.1 | 4.60 | 4.01 | 9.5 | 6.5 | 16.0 | 0.104 | 0.000 |

| 3/8 | 10 | 17.6 | 18.0 | 8.4 | 9.9 | 5.03 | 4.37 | 9.5 | 6.5 | 17.5 | 0.150 | 0.000 |

| 1/2 | 15 | 21.8 | 22.2 | 11.0 | 12.5 | 5.97 | 5.18 | 9.5 | 9.5 | 22.5 | 0.204 | 0.254 |

| 3/4 | 20 | 27.2 | 27.6 | 14.8 | 16.3 | 6.96 | 6.04 | 12.5 | 9.5 | 24.0 | 0.304 | 0.363 |

| 1 | 25 | 33.9 | 34.3 | 19.9 | 21.5 | 7.92 | 6.93 | 12.5 | 12.5 | 28.5 | 0.576 | 0.717 |

| 1-1/4 | 32 | 42.7 | 43.1 | 28.7 | 30.2 | 7.92 | 6.93 | 12.5 | 12.5 | 30.0 | 0.621 | 0.780 |

| 1-1/2 | 40 | 48.8 | 49.2 | 33.2 | 34.7 | 8.92 | 7.80 | 12.5 | 12.5 | 32.0 | 0.948 | 1.356 |

| 2 | 50 | 61.2 | 61.7 | 42.1 | 43.6 | 10.92 | 9.50 | 16.0 | 19.0 | 41.0 | 1.746 | 2.263 |

Socket Weld Coupling Dimensions - Class 9000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Socket Depth (J) | Laying Length | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Full Coupling (E) | Half Coupling (F) | Full Coupling | Half Coupling |

| 1/2 | 15 | 21.8 | 22.2 | 5.6 | 7.2 | 9.35 | 8.18 | 9.5 | 9.5 | 22.5 | 0.281 | 0.399 |

| 3/4 | 20 | 27.2 | 27.6 | 10.3 | 11.8 | 9.78 | 8.56 | 12.5 | 9.5 | 24.0 | 0.472 | 0.363 |

| 1 | 25 | 33.9 | 34.3 | 14.4 | 16.0 | 11.38 | 9.96 | 12.5 | 12.5 | 28.5 | 0.776 | 0.789 |

| 1-1/4 | 32 | 42.7 | 43.1 | 22.0 | 23.5 | 12.14 | 10.62 | 12.5 | 12.5 | 30.0 | 0.767 | 1.007 |

| 1-1/2 | 40 | 48.8 | 49.2 | 27.2 | 28.7 | 12.70 | 11.12 | 12.5 | 12.5 | 32.0 | 1.329 | 1.329 |

| 2 | 50 | 61.2 | 61.7 | 37.4 | 38.9 | 13.84 | 12.12 | 16.0 | 19.0 | 41.0 | 2.091 | 2.263 |

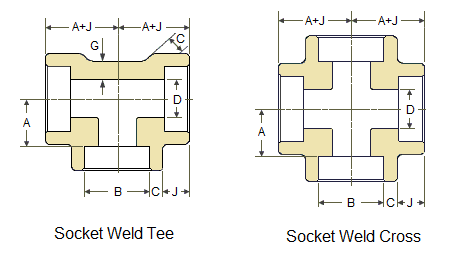

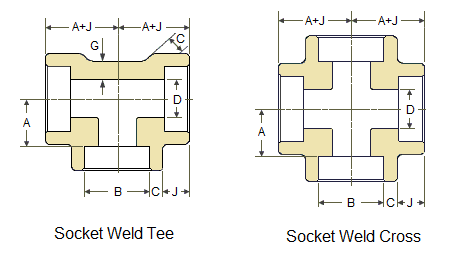

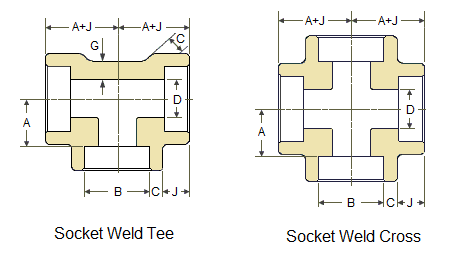

Socket Weld Tee and Cross Dimensions - Class 3000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | Tee | Cross | Tee | Cross |

| 1/8 | 6 | 10.8 | 11.2 | 6.1 | 7.6 | 3.18 | 3.18 | 2.41 | 9.5 | 11.0 | 8.0 | 0.150 | 0.113 |

| 1/4 | 8 | 14.2 | 14.6 | 8.5 | 10.0 | 3.78 | 3.30 | 3.02 | 9.5 | 11.0 | 8.0 | 0.122 | 0.113 |

| 3/8 | 10 | 17.6 | 18.0 | 11.8 | 13.3 | 4.01 | 3.50 | 3.20 | 9.5 | 13.5 | 8.0 | 0.154 | 0.191 |

| 1/2 | 15 | 21.8 | 22.2 | 15.0 | 16.6 | 4.67 | 4.09 | 3.73 | 9.5 | 15.5 | 11.0 | 0.268 | 0.327 |

| 3/4 | 20 | 27.2 | 27.6 | 20.2 | 21.7 | 4.90 | 4.27 | 3.91 | 12.5 | 19.0 | 13.0 | 0.426 | 0.531 |

| 1 | 25 | 33.9 | 34.3 | 25.9 | 27.4 | 5.69 | 4.98 | 4.55 | 12.5 | 22.5 | 14.0 | 0.585 | 0.676 |

| 1-1/4 | 32 | 42.7 | 43.1 | 34.3 | 35.8 | 6.07 | 5.28 | 4.85 | 12.5 | 27.0 | 17.5 | 0.925 | 1.080 |

| 1-1/2 | 40 | 48.8 | 49.2 | 40.1 | 41.6 | 6.35 | 5.54 | 5.08 | 12.5 | 32.0 | 20.5 | 1.256 | 1.474 |

| 2 | 50 | 61.2 | 61.7 | 51.7 | 53.3 | 6.93 | 6.04 | 5.54 | 16.0 | 38.0 | 25.5 | 1.864 | 2.304 |

| 2-1/2 | 65 | 73.9 | 74.4 | 61.2 | 64.2 | 8.76 | 7.67 | 7.01 | 16.0 | 41.0 | 28.5 | 3.937 | 7.158 |

| 3 | 80 | 89.8 | 90.3 | 76.4 | 79.4 | 9.52 | 8.30 | 7.62 | 16.0 | 57.0 | 32.0 | 6.255 | 11.217 |

| 4 | 100 | 115.2 | 115.7 | 100.7 | 103.8 | 10.69 | 9.35 | 8.56 | 19.0 | 66.5 | 41.0 | 12.973 | 18.144 |

Socket Weld Tee and Cross Dimensions - Class 6000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | Tee | Cross | Tee | Cross |

| 1/8 | 6 | 10.8 | 11.2 | 3.2 | 4.8 | 3.96 | 3.43 | 3.15 | 9.5 | 11 | 8.0 | 0.000 | 0.000 |

| 1/4 | 8 | 14.2 | 14.6 | 5.6 | 7.1 | 4.60 | 4.01 | 3.68 | 9.5 | 13.5 | 8.0 | 0.154 | 0.000 |

| 3/8 | 10 | 17.6 | 18.0 | 8.4 | 9.9 | 5.03 | 4.37 | 4.01 | 9.5 | 15.5 | 11.0 | 0.363 | 0.000 |

| 1/2 | 15 | 21.8 | 22.2 | 11.0 | 12.5 | 5.97 | 5.18 | 4.78 | 9.5 | 19.0 | 12.5 | 0.576 | 0.703 |

| 3/4 | 20 | 27.2 | 27.6 | 14.8 | 16.3 | 6.96 | 6.04 | 5.56 | 12.5 | 22.5 | 14.0 | 0.866 | 1.048 |

| 1 | 25 | 33.9 | 34.3 | 19.9 | 21.5 | 7.92 | 6.93 | 6.35 | 12.5 | 27.0 | 17.5 | 1.438 | 1.696 |

| 1-1/4 | 32 | 42.7 | 43.1 | 28.7 | 30.2 | 7.92 | 6.93 | 6.35 | 12.5 | 32.0 | 20.5 | 1.833 | 2.381 |

| 1-1/2 | 40 | 48.8 | 49.2 | 33.2 | 34.7 | 8.92 | 7.80 | 7.14 | 12.5 | 38.0 | 25.5 | 3.425 | 3.992 |

| 2 | 50 | 61.2 | 61.7 | 42.1 | 43.6 | 10.92 | 9.50 | 8.74 | 16.0 | 41.0 | 28.5 | 3.715 | 4.382 |

Socket Weld Tee and Cross Dimensions - Class 9000

| Nom Pipe Size | Socket Bore Dia (B) | Fitting Bore Dia (D) | Socket Wall Thk (C) | Body Wall Thk (G) | Socket Depth (J) | Center to bottom of socket (A) | Weight (kg) | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (inches) | (mm) | Min. | Max. | Min. | Max. | Avg. | Min. | Min. | Min. | Tee | Cross | Tee | Cross |

| 1/2 | 15 | 21.8 | 22.2 | 5.6 | 7.2 | 9.35 | 8.18 | 7.47 | 9.5 | 25.5 | 15.5 | 1.048 | 0.807 |

| 3/4 | 20 | 27.2 | 27.6 | 10.3 | 11.8 | 9.78 | 8.56 | 7.82 | 12.5 | 28.5 | 19.0 | 1.642 | 1.869 |

| 1 | 25 | 33.9 | 34.3 | 14.4 | 16.0 | 11.38 | 9.96 | 9.09 | 12.5 | 32.0 | 20.5 | 2.359 | 2.381 |

| 1-1/4 | 32 | 42.7 | 43.1 | 22.0 | 23.5 | 12.14 | 10.62 | 9.70 | 12.5 | 35.0 | 22.5 | 3.425 | 2.322 |

| 1-1/2 | 40 | 48.8 | 49.2 | 27.2 | 28.7 | 12.70 | 11.12 | 10.15 | 12.5 | 38.0 | 25.5 | 4.890 | 3.969 |

| 2 | 50 | 61.2 | 61.7 | 37.4 | 38.9 | 13.84 | 12.12 | 11.07 | 16.0 | 54.0 | 28.5 | 7.162 | 10.065 |

Steel Alloys Physical, Thermal, and Electrical Properties And More

| Physical Properties | Metric | Comments |

|---|---|---|

| Density | 0.190 - 9.01 g/cc | Average value: 7.79 g/cc Grade Count:1432 |

| Porosity | 0.000 - 5.00 % | Average value: 2.97 % Grade Count:15 |

| Particle Size | 0.000 - 300 µm | Average value: 37.9 µm Grade Count:88 |

| Permeability | 0.0150 - 1.00 | Average value: 0.509 Grade Count:4 |

| Thickness | 20.0 - 508 microns | Average value: 86.8 microns Grade Count:14 |

| Mechanical Properties | Metric | Comments |

| Hardness, Brinell | 80.0 - 600 | Average value: 251 Grade Count:564 |

| Hardness, Knoop | 97.0 - 662 | Average value: 301 Grade Count:276 |

| Hardness, Rockwell A | 51.1 - 58.0 | Average value: 54.0 Grade Count:8 |

| Hardness, Rockwell B | 37.0 - 130 | Average value: 86.2 Grade Count:503 |

| Hardness, Rockwell C | 10.0 - 71.0 | Average value: 39.6 Grade Count:447 |

| Hardness, Vickers | 82.0 - 1100 | Average value: 294 Grade Count:339 |

| Tensile Strength, Ultimate | 32.3 - 3100 MPa | Average value: 935 MPa Grade Count:1729 |

| Tensile Strength, Yield | 25.0 - 2500 MPa | Average value: 669 MPa Grade Count:1638 |

| Elongation at Break | 0.000 - 88.0 % | Average value: 26.5 % Grade Count:1583 |

| Elongation at Yield | 0.000 - 62.0 % | Average value: 22.7 % Grade Count:22 |

| Reduction of Area | 0.500 - 88.0 % | Average value: 49.3 % Grade Count:308 |

| Modulus of Elasticity | 2.36 - 310 GPa | Average value: 196 GPa Grade Count:1175 |

| Flexural Yield Strength | 58.0 - 938 MPa | Average value: 479 MPa Grade Count:4 |

| Compressive Yield Strength | 262 - 3000 MPa | Average value: 1080 MPa Grade Count:11 |

| Notched Tensile Strength | 710 - 2230 MPa | Average value: 1740 MPa Grade Count:30 |

| Bulk Modulus | 166 GPa | Average value: 166 GPa Grade Count:14 |

| Poissons Ratio | 0.120 - 0.380 | Average value: 0.282 Grade Count:310 |

| Fatigue Strength | 85.0 - 1070 MPa | Average value: 439 MPa Grade Count:54 |

| Fracture Toughness | 17.6 - 165 MPa-m½ | Average value: 90.9 MPa-m½ Grade Count:9 |

| Machinability | 18.0 - 65.0 % | Average value: 31.7 % Grade Count:126 |

| Shear Modulus | 62.1 - 86.5 GPa | Average value: 77.6 GPa Grade Count:324 |

| Shear Strength | 74.5 - 597 MPa | Average value: 358 MPa Grade Count:5 |

| Izod Impact | 16.3 - 208 J | Average value: 115 J Grade Count:140 |

| Izod Impact Unnotched | 13.6 - 149 J | Average value: 77.8 J Grade Count:13 |

| Charpy Impact | 0.500 - 404 J | Average value: 115 J Grade Count:253 |

| Charpy Impact, Unnotched | 7.46 - 294 J | Average value: 157 J Grade Count:9 |

| Charpy Impact Unnotched | 1.59 - 60.0 J/cm² | Average value: 22.0 J/cm² Grade Count:3 |

| Charpy Impact, Notched | 0.710 - 294 J/cm² | Average value: 137 J/cm² Grade Count:5 |

| Taber Abrasion, mg/1000 Cycles | 3.20 - 30.0 | Average value: 11.3 Grade Count:3 |

| Electrical Properties | Metric | Comments |

| Electrical Resistivity | 0.00000450 - 0.000145 ohm-cm | Average value: 0.0000729 ohm-cm Grade Count:962 |

| Magnetic Permeability | 1.00 - 3000 | Average value: 178 Grade Count:316 |

| Magnetic Coercive Force, Hc | 1.20 - 7.00 Oe | Average value: 2.40 Oe Grade Count:6 |

| Magnetic Saturation Flux Density, Bmax | 11900 - 17000 Gauss | Average value: 15000 Gauss Grade Count:6 |

| Magnetic Remanence, Br | 2500 - 8500 Gauss | Average value: 6000 Gauss Grade Count:6 |

| Curie Temperature | -115 - 732 °C | Average value: 266 °C Grade Count:14 |

| Thermal Properties | Metric | Comments |

| CTE, linear | 7.02 - 21.1 µm/m-°C | Average value: 15.4 µm/m-°C Grade Count:977 |

| Specific Heat Capacity | 0.200 - 0.850 J/g-°C | Average value: 0.478 J/g-°C Grade Count:934 |

| Thermal Conductivity | 10.0 - 34.3 W/m-K | Average value: 16.7 W/m-K Grade Count:567 |

| Melting Point | 1230 - 1530 °C | Average value: 1440 °C Grade Count:580 |

| Solidus | 1230 - 1480 °C | Average value: 1410 °C Grade Count:553 |

| Liquidus | 1360 - 1530 °C | Average value: 1460 °C Grade Count:553 |

| Maximum Service Temperature, Air | 100 - 1400 °C | Average value: 837 °C Grade Count:368 |

| Minimum Service Temperature, Air | -200 - -30.0 °C | Average value: -133 °C Grade Count:26 |

| Optical Properties | Metric | Comments |

| Emissivity (0-1) | 0.7 | Average value: 0.700 Grade Count:4 |

| Processing Properties | Metric | Comments |

| Processing Temperature | 382 - 863 °C | Average value: 767 °C Grade Count:4 |

| Annealing Temperature | 593 - 1200 °C | Average value: 977 °C Grade Count:31 |

| Hot-Working Temperature | 482 - 1290 °C | Average value: 960 °C Grade Count:13 |

Find out in detail about the steel socket weld fittings, including the mechanical properties, weight, dimensions, sizes and physical properties on our downloadable PDF Chart. Our website has a comprehensive table that highlights all these major properties of the discussed metal, which also simplifies the process of making decisions for several industrial applications. Whether you are looking for data to decide which fittings to use for a project or to understand the performance of certain alloys the resource we provide is a quick and easy reference. In our chart, parameters such as tensile strength, corrosion resistance are indicated, helping engineers, building contractors, and those getting project supplies in carrying out efficient and improved operations. Ensuring the compatibility, durability, and efficiency of your piping systems is now easier than ever as you can access the necessary details at ease. Visit our website to discover this essential information for your piping care.