Copper Socket Weld Fittings Mechanical, Weight, Dimension, Size and Physical Properties Chart Pdf, Table

Copper socket weld fittings have an important role in piping systems, which is based on its mechanical strength and endurance. These joints are installed on piping ends in order to make reliable secure connections in numerous industrial processes. These fittings are offered in a variety of sizes and shapes, necessary for any piping application, giving the user the freedom to choose the best fitting for the task and ease of installation. Copper socket weld fittings show top physical properties such as resistance to corrosion and high thermal conductivity which makes them applicable in a wide range of environments. In this website we have a chart in PDF format and a table with relevant statistics and data, which explains the mechanical specifications, applied force, dimensions, sizes, and physical properties of copper socket weld fittings. Whether you're a plumbing professional or a do-it-yourself, our website will provide you with up-to-date information to make the right decision regarding the fittings for your ventures.

C- FIT ASTM B280 / ASTM B88 / ASME B16.22 Copper Standard Refrigeration (HVAC) Grade Socket Weld Fittings (Elbow, Coupling, Tee, U Bend, End Cap) Dimension, Size, Gauge and Weight Table

| Size (in) | DIAMETER (mm) | GAUGE | THICKNESS (mm) | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|

| 5/16" | 8 | 22 | 0.7 | 100 | 2000 |

| 1/4 | 6.35 | 22 | 0.7 | 100 | 2000 |

| 3/8 | 9.05 | 21 | 0.8 | 100 | 1500 |

| 1/2 | 12.7 | 21 | 0.8 | 100 | 1000 |

| 5/8 | 15.9 | 21 | 0.8 | 50 | 500 |

| 3/4 | 19 | 20 | 0.9 | 50 | 500 |

| 7/8 | 22.2 | 20 | 0.9 | 25 | 200 |

| 1 | 25.4 | 20 | 0.9 | 25 | 200 |

| 1.1/8" | 28.6 | 19 | 1 | 10 | 50 |

| 1 1/4" | 31.8 | 19 | 1 | 10 | 50 |

| 1.3/8 | 34.9 | 18 | 1.2 | 5 | 25 |

| 1-1/2" | 38.1 | 18 | 1.2 | 5 | 25 |

| 1.5/8 | 41.3 | 18 | 1.2 | 5 | 25 |

| 2 | 50.8 | 16 | 1.6 | 5 | 25 |

| 2.1/8 | 54 | 16 | 1.6 | 5 | 20 |

| 2.5/8 | 66.7 | 16 | 1.6 | 4 | 20 |

| 3 | 76 | 16 | 1.6 | 4 | 20 |

| 3.1/8 | 79.4 | 16 | 1.6 | 1 | 10 |

| 3.5/8 | 92.1 | 16 | 1.6 | 1 | 5 |

| 4.1/8 | 104 | 16 | 1.6 | 1 | 5 |

| 4.5/8 | 120 | 16 | 1.6 | 1 | 4 |

C- FIT ASTM B280 / ASTM B88 / ASME B16.22 Copper VRV/VRF 18 SWG Socket Weld Fittings (Elbow, Coupling, Tee, End Cap) Dimension, Size, Gauge and Weight Table

| Size (in) | DIAMETER (mm) | GAUGE | THICKNESS (mm) | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|

| 5/16" | 8 | 18 | 1.2 | 100 | 2000 |

| 1/4 | 6.35 | 18 | 1.2 | 100 | 2000 |

| 3/8 | 9.05 | 18 | 1.2 | 100 | 1500 |

| 1/2 | 12.7 | 18 | 1.2 | 100 | 1000 |

| 5/8 | 15.9 | 18 | 1.2 | 50 | 500 |

| 3/4 | 19 | 18 | 1.2 | 50 | 500 |

| 7/8 | 22.2 | 18 | 1.2 | 25 | 200 |

| 1 | 25.4 | 18 | 1.2 | 25 | 200 |

| 1.1/8" | 28.6 | 18 | 1.2 | 10 | 50 |

| 1 1/4" | 31.8 | 18 | 1.2 | 10 | 50 |

| 1.3/8 | 34.9 | 18 | 1.2 | 5 | 25 |

| 1-1/2" | 38.1 | 18 | 1.2 | 5 | 25 |

| 1.5/8 | 41.3 | 18 | 1.2 | 5 | 25 |

| 2 | 50.8 | 16 | 1.6 | 5 | 25 |

| 2.1/8 | 54 | 16 | 1.6 | 5 | 20 |

| 2.5/8 | 66.7 | 16 | 1.6 | 4 | 20 |

| 3 | 76 | 16 | 1.6 | 4 | 20 |

| 3.1/8 | 79.4 | 16 | 1.6 | 1 | 10 |

| 3.5/8 | 92.1 | 16 | 1.6 | 1 | 5 |

| 4.1/8 | 104 | 16 | 1.6 | 1 | 5 |

| 4.5/8 | 120 | 16 | 1.6 | 1 | 4 |

C- FIT ASTM B280 / ASTM B88 / ASME B16.22 Copper VRV/VRF 16 SWG Socket Weld Fittings (Elbow, Coupling, Tee, End Cap) Dimension, Size, Gauge and Weight Table

| Size (in) | DIAMETER (mm) | GAUGE | THICKNESS (mm) | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|

| 5/16" | 8 | 16 | 1.6 | 100 | 2000 |

| 1/4 | 6.35 | 16 | 1.6 | 100 | 2000 |

| 3/8 | 9.05 | 16 | 1.6 | 100 | 1500 |

| 1/2 | 12.7 | 16 | 1.6 | 100 | 1000 |

| 5/8 | 15.9 | 16 | 1.6 | 50 | 500 |

| 3/4 | 19 | 16 | 1.6 | 50 | 500 |

| 7/8 | 22.2 | 16 | 1.6 | 25 | 200 |

| 1 | 25.4 | 16 | 1.6 | 25 | 200 |

| 1.1/8" | 28.6 | 16 | 1.6 | 10 | 50 |

| 1 1/4" | 31.8 | 16 | 1.6 | 10 | 50 |

| 1.3/8 | 34.9 | 16 | 1.6 | 5 | 25 |

| 1-1/2" | 38.1 | 16 | 1.6 | 5 | 25 |

| 1.5/8 | 41.3 | 16 | 1.6 | 5 | 25 |

| 2 | 50.8 | 16 | 1.6 | 5 | 25 |

| 2.1/8 | 54 | 16 | 1.6 | 5 | 20 |

| 2.5/8 | 66.7 | 16 | 1.6 | 4 | 20 |

| 3 | 76 | 16 | 1.6 | 4 | 20 |

| 3.1/8 | 79.4 | 16 | 1.6 | 1 | 10 |

| 3.5/8 | 92.1 | 16 | 1.6 | 1 | 5 |

| 4.1/8 | 104 | 16 | 1.6 | 1 | 5 |

| 4.5/8 | 120 | 16 | 1.6 | 1 | 4 |

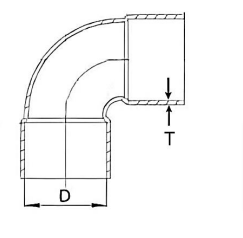

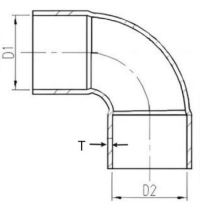

C- FIT BS EN 13348 / BS EN 1057 Copper 90° Elbow (F x F) Socket Weld Fittings Dimension, Size and Weight Table

| PART 1 | SIZE | Diameter (D) | Thickness (T) | SWG | INNER BOX QTY |

OUTER BOX QTY

|

|---|---|---|---|---|---|---|

| CF9E0010 | 10mm | 10 | 0.7 | 22 | 25 | 2000 |

| CF9E0012 | 12mm | 12 | 0.7 | 22 | 25 | 1000 |

| CF9E0015 | 15mm | 15 | 0.9 | 20 | 25 | 650 |

| CF9E0022 | 22mm | 22 | 0.9 | 20 | 10 | 300 |

| CF9E0028 | 28mm | 28 | 0.9 | 20 | 10 | 180 |

| CF9E0035 | 35mm | 35 | 1.2 | 18 | 10 | 80 |

| CF9E042 | 42mm | 42 | 1.2 | 18 | 5 | 30 |

| CF9E054 | 54mm | 54 | 1.2 | 18 | 1 | 12 |

| CF9E076 | 76mm | 76 | 1.5 | 16 | 1 | 2 |

| CF9E0108 | 108mm | 108 | 2.5 | 10 | 1 | 1 |

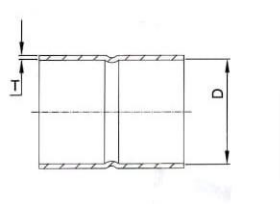

C- FIT BS EN 13348 / BS EN 1057 Copper Socket (Coupling F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter (D) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|

| CFSC0010 | 10mm | 10 | 0.7 | 22 | 25 | 3000 |

| CFSC0012 | 12mm | 12 | 0.7 | 22 | 25 | 2000 |

| CFSC0015 | 15mm | 15 | 0.9 | 20 | 25 | 1200 |

| CFSC0022 | 22mm | 22 | 0.9 | 20 | 25 | 650 |

| CFSC0028 | 28mm | 28 | 0.9 | 20 | 10 | 280 |

| CFSC0035 | 35mm | 35 | 1.2 | 18 | 10 | 100 |

| CFSC042 | 42mm | 42 | 1.2 | 18 | 10 | 60 |

| CFSC054 | 54mm | 54 | 1.2 | 18 | 5 | 20 |

| CFSC076 | 76mm | 76 | 1.5 | 16 | 2 | 6 |

| CFSC0108 | 108mm | 108 | 2.5 | 10 | 1 | 1 |

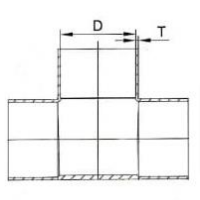

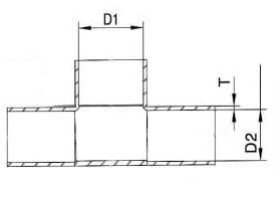

C- FIT BS EN 13348 / BS EN 1057 Copper Tee (F x F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter (D) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|

| CFET0010 | 10mm | 10 | 0.7 | 22 | 25 | 1000 |

| CFET0012 | 12mm | 12 | 0.7 | 22 | 25 | 650 |

| CFET0015 | 15mm | 15 | 0.9 | 20 | 255 | 300 |

| CFET0022 | 22mm | 22 | 0.9 | 20 | 10 | 120 |

| CFET0028 | 28mm | 28 | 0.9 | 20 | 10 | 80 |

| CFET0035 | 35mm | 35 | 1.2 | 18 | 4 | 32 |

| CFET042 | 42mm | 42 | 1.2 | 18 | 2 | 6 |

| CFET054 | 54mm | 54 | 1.2 | 18 | 1 | 2 |

| CFET076 | 76mm | 76 | 1.5 | 16 | 1 | 1 |

| CFET0108 | 108mm | 108 | 2.5 | 10 | 1 | 1 |

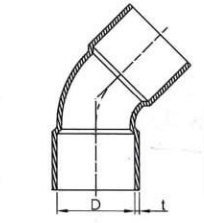

C- FIT BS EN 13348 / BS EN 1057 Copper 45° Elbow (F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter (D) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|

|

CF4E0010

|

10mm | 10 | 0.7 | 22 | 25 | 2000 |

|

CF4E0012

|

12mm | 12 | 0.7 | 22 | 25 | 1000 |

|

CF4E0015

|

15mm | 15 | 0.9 | 20 | 25 | 650 |

|

CF4E0022

|

22mm | 22 | 0.9 | 20 | 10 | 300 |

|

CF4E0028

|

28mm | 28 | 0.9 | 20 | 10 | 180 |

|

CF4E0035

|

35mm | 35 | 1.2 | 18 | 10 | 80 |

| CF4E042 | 42mm | 42 | 1.2 | 18 | 5 | 30 |

| CF4E054 | 54mm | 54 | 1.2 | 18 | 1 | 12 |

| CF4E076 | 76mm | 76 | 1.5 | 16 | 1 | 2 |

|

CF4E0108

|

108mm | 108 | 2.5 | 10 | 1 | 1 |

C- FIT BS EN 13348 / BS EN 1057 Copper Reducing Tee (F x F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter 1 (D1) | Diameter (D2) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|---|

| CFRT1510 | 15x10mm | 15 | 10 | 0.9 | 20 | 25 | 300 |

| CFRT01512 | 15x12mm | 15 | 12 | 0.9 | 20 | 25 | 300 |

| CFRT2210 | 22x10mm | 22 | 10 | 0.9 | 20 | 10 | 120 |

| CFRT2212 | 22x12mm | 22 | 12 | 0.9 | 20 | 10 | 120 |

| CFRT2215 | 22x15mm | 22 | 15 | 0.9 | 20 | 10 | 120 |

| CFRT2815 | 28x15mm | 28 | 15 | 0.9 | 20 | 10 | 80 |

| CFRT2822 | 28x22mm | 28 | 22 | 0.9 | 20 | 10 | 80 |

| CFRT3515 | 35x15mm | 35 | 15 | 1.2 | 18 | 4 | 32 |

| CFRT3522 | 35x22mm | 35 | 22 | 1.2 | 18 | 4 | 32 |

| CFRT3528 | 35x28mm | 35 | 28 | 1.2 | 18 | 4 | 32 |

| CFRT4215 | 42x15mm | 42 | 15 | 1.2 | 18 | 2 | 6 |

| CFRT4222 | 42x22mm | 42 | 22 | 1.2 | 18 | 2 | 6 |

| CFRT4228 | 42x28mm | 42 | 28 | 1.2 | 18 | 2 | 6 |

| CFRT4235 | 42x35mm | 42 | 35 | 1.2 | 18 | 2 | 6 |

| CFRT5422 | 54x22mm | 54 | 22 | 1.2 | 18 | 1 | 2 |

| CFRT5428 | 54x28mm | 54 | 38 | 1.2 | 18 | 1 | 2 |

| CFRT5435 | 54x35mm | 54 | 35 | 1.2 | 18 | 1 | 2 |

| CFRT5442 | 54x42mm | 54 | 42 | 1.2 | 18 | 1 | 2 |

| CFRT7642 | 76x42mm | 76 | 42 | 1.5 | 16 | 1 | 1 |

| CFRT7654 | 76x54mm | 76 | 54 | 1.5 | 16 | 1 | 1 |

| CFRT7667 | 76x67mm | 76 | 67 | 1.5 | 16 | 1 | 1 |

| CFRT10876 | 108x76mm | 108 | 76 | 2.5 | 10 | 1 | 1 |

C- FIT BS EN 13348 / BS EN 1057 Copper 90°Reducing Elbow (F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter 1 (D1) | Diameter (D2) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|---|

| CFRE1510 | 15x10mm | 15 | 10 | 0.9 | 20 | 25 | 650 |

| CFRE01512 | 15x12mm | 15 | 12 | 0.9 | 20 | 25 | 650 |

| CFRE2210 | 22x10mm | 22 | 10 | 0.9 | 20 | 10 | 300 |

| CFRE2212 | 22x12mm | 22 | 12 | 0.9 | 20 | 10 | 300 |

| CFRE2215 | 22x15mm | 22 | 15 | 0.9 | 20 | 10 | 300 |

| CFRE2815 | 28x15mm | 28 | 15 | 0.9 | 20 | 10 | 180 |

| CFRE2822 | 28x22mm | 28 | 22 | 0.9 | 20 | 10 | 180 |

| CFRE3515 | 35x15mm | 35 | 15 | 1.2 | 18 | 10 | 80 |

| CFRE3522 | 35x22mm | 35 | 22 | 1.2 | 18 | 10 | 80 |

| CFRE3528 | 35x28mm | 35 | 28 | 1.2 | 18 | 10 | 80 |

| CFRE4215 | 42x15mm | 42 | 15 | 1.2 | 18 | 5 | 30 |

| CFRE4222 | 42x22mm | 42 | 22 | 1.2 | 18 | 5 | 30 |

| CFRE4228 | 42x28mm | 42 | 28 | 1.2 | 18 | 5 | 30 |

| CFRE4235 | 42x35mm | 42 | 35 | 1.2 | 18 | 5 | 30 |

| CFRE5422 | 54x22mm | 54 | 22 | 1.2 | 18 | 1 | 12 |

| CFRE5428 | 54x28mm | 54 | 38 | 1.2 | 18 | 1 | 12 |

| CFRE5435 | 54x35mm | 54 | 35 | 1.2 | 18 | 1 | 12 |

| CFRE5442 | 54x42mm | 54 | 42 | 1.2 | 18 | 1 | 12 |

| CFRE7642 | 76x42mm | 76 | 42 | 1.5 | 16 | 1 | 2 |

| CFRE7654 | 76x54mm | 76 | 54 | 1.5 | 16 | 1 | 2 |

| CFRE7667 | 76x67mm | 76 | 67 | 1.5 | 16 | 1 | 2 |

| CFRE10876 | 108x76mm | 108 | 76 | 2.5 | 10 | 1 | 1 |

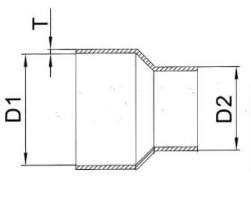

C- FIT BS EN 13348 / BS EN 1057 Copper Reducer (Coupling F x F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter 1 (D1) | Diameter (D2) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|---|

| CFRC1510 | 15x10mm | 15 | 10 | 0.9 | 20 | 25 | 1200 |

| CFRC1512 | 15x12mm | 15 | 12 | 0.9 | 20 | 25 | 1200 |

| CFRC2210 | 22x10mm | 22 | 10 | 0.9 | 20 | 25 | 650 |

| CFRC2212 | 22x12mm | 22 | 12 | 0.9 | 20 | 25 | 650 |

| CFRC2215 | 22x15mm | 22 | 15 | 0.9 | 20 | 25 | 650 |

| CFRC2815 | 28x15mm | 28 | 15 | 0.9 | 20 | 10 | 280 |

| CFRC2822 | 28x22mm | 28 | 22 | 0.9 | 20 | 10 | 280 |

| CFRC3515 | 35x15mm | 35 | 15 | 1.2 | 18 | 10 | 100 |

| CFRC3522 | 35x22mm | 35 | 22 | 1.2 | 18 | 10 | 100 |

| CFRC3528 | 35x28mm | 35 | 28 | 1.2 | 18 | 10 | 100 |

| CFRC4215 | 42x15mm | 42 | 15 | 1.2 | 18 | 10 | 60 |

| CFRC4222 | 42x22mm | 42 | 22 | 1.2 | 18 | 10 | 60 |

| CFRC4228 | 42x28mm | 42 | 28 | 1.2 | 18 | 10 | 60 |

| CFRC4235 | 42x35mm | 42 | 35 | 1.2 | 18 | 10 | 60 |

| CFRC5422 | 54x22mm | 54 | 22 | 1.2 | 18 | 5 | 20 |

| CFRC5428 | 54x28mm | 54 | 38 | 1.2 | 18 | 5 | 20 |

| CFRC5435 | 54x35mm | 54 | 35 | 1.2 | 18 | 5 | 20 |

| CFRC5442 | 54x42mm | 54 | 42 | 1.2 | 18 | 5 | 20 |

| CFRC7642 | 76x42mm | 76 | 42 | 1.5 | 16 | 2 | 6 |

| CFRC7654 | 76x54mm | 76 | 54 | 1.5 | 16 | 2 | 6 |

| CFRC7667 | 76x67mm | 76 | 67 | 1.5 | 16 | 2 | 6 |

| CFRC10876 | 108x76mm | 108 | 76 | 2.5 | 10 | 1 | 1 |

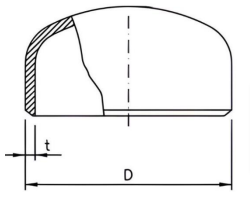

C- FIT BS EN 13348 / BS EN 1057 Copper End Cap (F) Socket Weld Fittings Dimension, Size, Gauge and Weight Table

| PART 1 | SIZE | Diameter (D) | Thickness (T) | SWG | INNER BOX QTY | OUTER BOX QTY |

|---|---|---|---|---|---|---|

| CFEC0010 | 10mm | 10 | 0.7 | 22 | 50 | 5000 |

| CFEC0012 | 12mm | 12 | 0.7 | 22 | 50 | 4000 |

| CFEC0015 | 15mm | 15 | 0.9 | 20 | 50 | 3200 |

| CFEC0022 | 22mm | 22 | 0.9 | 20 | 50 | 2400 |

| CFEC0028 | 28mm | 28 | 0.9 | 20 | 25 | 1600 |

| CFEC0035 | 35mm | 35 | 1.2 | 18 | 25 | 1000 |

| CFEC042 | 42mm | 42 | 1.2 | 18 | 25 | 500 |

| CFEC054 | 54mm | 54 | 1.2 | 18 | 10 | 200 |

| CFEC076 | 76mm | 76 | 1.5 | 16 | 10 | 120 |

| CFEC0108 | 108mm | 108 | 2.5 | 10 | 4 | 40 |

C- FIT BS EN 13348 / BS EN 1057 Copper Alloys Physical, Thermal, and Electrical Properties

| Physical Properties | Original Value | Comments |

|---|---|---|

| Density | 0.325 - 23.1 g/cc | Average value: 8.65 g/cc Grade Count:4395 |

| Porosity | 0.400 - 95.0 % | Average value: 18.8 % Grade Count:10 |

| Particle Size | 0.0220 - 105 µm | Average value: 15.2 µm Grade Count:32 |

| Molecular Weight | 63.5 g/mol | Average value: 63.5 g/mol Grade Count:4 |

| Thickness | 2.00 - 140 microns | Average value: 56.8 microns Grade Count:12 |

| Chemical Properties | Original Value | Comments |

| Thermal Neutron Cross Section | 3.80 barns/atom | Average value: 3.80 barns/atom Grade Count:3 |

| Electrode Potential | -0.520 - -0.340 V | Average value: -0.430 V Grade Count:3 |

| Mechanical Properties | Original Value | Comments |

| Hardness, Brinell | 11.6 - 420 | Average value: 129 Grade Count:360 |

| Hardness, Rockwell B | 6.00 - 150 | Average value: 69.3 Grade Count:1561 |

| Hardness, Rockwell C | 18.0 - 100 | Average value: 33.2 Grade Count:276 |

| Hardness, Rockwell F | 8.00 - 110 | Average value: 70.3 Grade Count:665 |

| Hardness, Rockwell 30T | 4.00 - 240 | Average value: 57.4 Grade Count:821 |

| Hardness, Rockwell HR30N | 37.0 - 80.0 | Average value: 54.1 Grade Count:30 |

| Hardness, Rockwell H | 45.0 - 90.0 | Average value: 70.7 Grade Count:20 |

| Hardness, Vickers | 18.0 - 475 | Average value: 210 Grade Count:536 |

| Tensile Strength, Ultimate | 0.250 - 2170 MPa | Average value: 507 MPa Grade Count:4352 |

| Tensile Strength, Yield | 0.250 - 1590 MPa | Average value: 390 MPa Grade Count:3863 |

| Elongation at Break | 0.000 - 80.0 % | Average value: 21.2 % Grade Count:4149 |

| Elongation at Yield | 5.00 - 15.0 % | Average value: 9.60 % Grade Count:5 |

| Reduction of Area | 0.000 - 80.0 % | Average value: 42.3 % Grade Count:125 |

| Creep Strength | 0.0758 - 228 MPa | Average value: 85.4 MPa Grade Count:10 |

| Modulus of Elasticity | 0.0960 - 250 GPa | Average value: 117 GPa Grade Count:3985 |

| Flexural Yield Strength | 216 - 908 MPa | Average value: 550 MPa Grade Count:36 |

| Flexural Modulus | 0.162 - 0.190 GPa | Average value: 0.177 GPa Grade Count:12 |

| Compressive Yield Strength | 48.3 - 2580 MPa | Average value: 543 MPa Grade Count:179 |

| Bearing Yield Strength | 207 - 262 MPa | Average value: 241 MPa Grade Count:3 |

| Bulk Modulus | 140 GPa | Average value: 140 GPa Grade Count:3 |

| Poissons Ratio | 0.181 - 0.460 | Average value: 0.323 Grade Count:2369 |

| Fatigue Strength | 0.276 - 552 MPa | Average value: 187 MPa Grade Count:591 |

| Machinability | 2.00 - 400 % | Average value: 36.2 % Grade Count:2830 |

| Shear Modulus | 25.5 - 115 GPa | Average value: 44.2 GPa Grade Count:2458 |

| Shear Strength | 44.0 - 538 MPa | Average value: 235 MPa Grade Count:1042 |

| Izod Impact | 2.70 - 115 J | Average value: 32.7 J Grade Count:109 |

| Izod Impact, Unnotched | 0.620 - 1.30 J/cm | Average value: 0.963 J/cm Grade Count:3 |

| Charpy Impact | 2.70 - 135 J | Average value: 44.7 J Grade Count:207 |

| Charpy Impact, Unnotched | 4.07 - 75.9 J | Average value: 23.8 J Grade Count:7 |

| Coefficient of Friction | 0.100 - 0.530 | Average value: 0.388 Grade Count:20 |

| Coefficient of Friction, Static | 0.530 - 1.05 | Average value: 0.753 Grade Count:19 |

| Peel Strength | 0.329 - 0.438 kN/m | Average value: 0.383 kN/m Grade Count:6 |

| Bend Radius, Minimum | 0.000 - 8.00 t | Average value: 1.64 t Grade Count:18 |

| Electrical Properties | Original Value | Comments |

| Electrical Resistivity | 0.00000167 - 0.0108 ohm-cm | Average value: 0.0000153 ohm-cm Grade Count:4102 |

| Surface Resistance | 0.0300 - 0.300 ohm | Average value: 0.127 ohm Grade Count:3 |

| Magnetic Permeability | 0.800 - 80.0 | Average value: 3.53 Grade Count:341 |

| Magnetic Susceptibility | -0.0000125 - -8.00e-8 | Average value: -0.00000143 Grade Count:75 |

| Shielding Effectiveness | 65.0 - 110 dB | Average value: 87.1 dB Grade Count:4 |

| Thermal Properties | Original Value | Comments |

| CTE, linear | 6.00 - 160 µm/m-°C | Average value: 17.7 µm/m-°C Grade Count:2389 |

| Specific Heat Capacity | 0.115 - 0.510 J/g-°C | Average value: 0.384 J/g-°C Grade Count:2776 |

| Thermal Conductivity | 1.01 - 457 W/m-K | Average value: 108 W/m-K Grade Count:3874 |

| Melting Point | 178 - 3410 °C | Average value: 997 °C Grade Count:3730 |

| Solidus | 178 - 1230 °C | Average value: 965 °C Grade Count:3018 |

| Liquidus | 547 - 3410 °C | Average value: 1020 °C Grade Count:3385 |

| Boiling Point | 1400 - 2570 °C | Average value: 1770 °C Grade Count:35 |

| Maximum Service Temperature, Air | 60.0 - 1000 °C | Average value: 316 °C Grade Count:49 |

| Softening Point | 355 - 800 °C | Average value: 399 °C Grade Count:27 |

| Annealing Point | 21.1 - 1040 °C | Average value: 567 °C Grade Count:1823 |

| Minimum Service Temperature, Air | -34.0 - -18.0 °C | Average value: -23.1 °C Grade Count:7 |

| Optical Properties | Original Value | Comments |

| Reflection Coefficient, Visible (0-1) | 0.630 - 0.700 | Average value: 0.694 Grade Count:38 |

| Processing Properties | Original Value | Comments |

| Processing Temperature | 149 - 1180 °C | Average value: 539 °C Grade Count:497 |

| Annealing Temperature | 225 - 950 °C | Average value: 593 °C Grade Count:1332 |

| Solution Temperature | 249 - 1100 °C | Average value: 852 °C Grade Count:356 |

| Aging Temperature | 260 - 510 °C | Average value: 402 °C Grade Count:222 |

| Hot-Working Temperature | 316 - 1070 °C | Average value: 805 °C Grade Count:1833 |

| Precipitation Temperature | 304 - 510 °C | Average value: 414 °C Grade Count:288 |

| Casting Temperature | 955 - 1430 °C | Average value: 1120 °C Grade Count:44 |

| Recrystallization Temperature | 288 - 870 °C | Average value: 449 °C Grade Count:416 |

Explore the comprehensive information on the steel alloy socket weld fittings including material properties, weight specifications, dimensions, sizes, and physical attributes in our PDF chart and table of details. Through our website, you will be able to explore the data in an organized manner concerning these solutions. Whether it is mechanical strength or dimensional accuracy, obtain knowledge about socket weld fittings to assist in your decision making processes. The tables represent different dimensions, thus, by taking the information from its charts an engineer, designer or any other person can get the point of help on the choice of a right steel alloy fitting in his application. Comprehensive and well organized format of the PDF page will serve as a guide in rapid identification of steel alloys socket weld fittings properties and specifications.

Technical Data

- Working Pressure 16 Bar @ 95°C

- Weight and thickness maintained compliant to EN 13348 / EN 1254.

- Tolerance maintained below 2%

Applicable Standards

- WRAS approved

- For use with Copper Tubing conformant to EN 13348 / EN 1057

- Manufactured to EN 13348 / EN 1254 standard

Features & Benefits

- 100% Degreased. Safe for Medical Gas use.

- WRAS Compliant. Safe for Water Plumbing

- Durable and secure leakproof joint

- Braze-able. Permanent Joint. Copper Brazing required

- Smooth ends. Huge time and resource savings

- 15 years warranty

- Works perfectly with all major pipe brands (Minimum or no tolerance)

- Polished to retain its color for a longer period

Material Specifications

| Description | Materials |

|---|---|

| Body | COPPER |

| ISO Certified | ISO 9001:2015 |

| Degreased | YES |

| Preservatives | SILICA GEL |